Pipe roofing heave monitoring system and method applied to pipe roofing box culvert construction

A monitoring system and settlement monitoring technology, applied in measuring devices, surveying and navigation, measuring inclination, etc., can solve the problem that pipe screens cannot provide vertical rulers and external stand observations, it is difficult to install static levels, and it is difficult to provide stable reference points and other issues, to achieve the effect of easy automation, good practicability and flexibility of use, and small plane size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

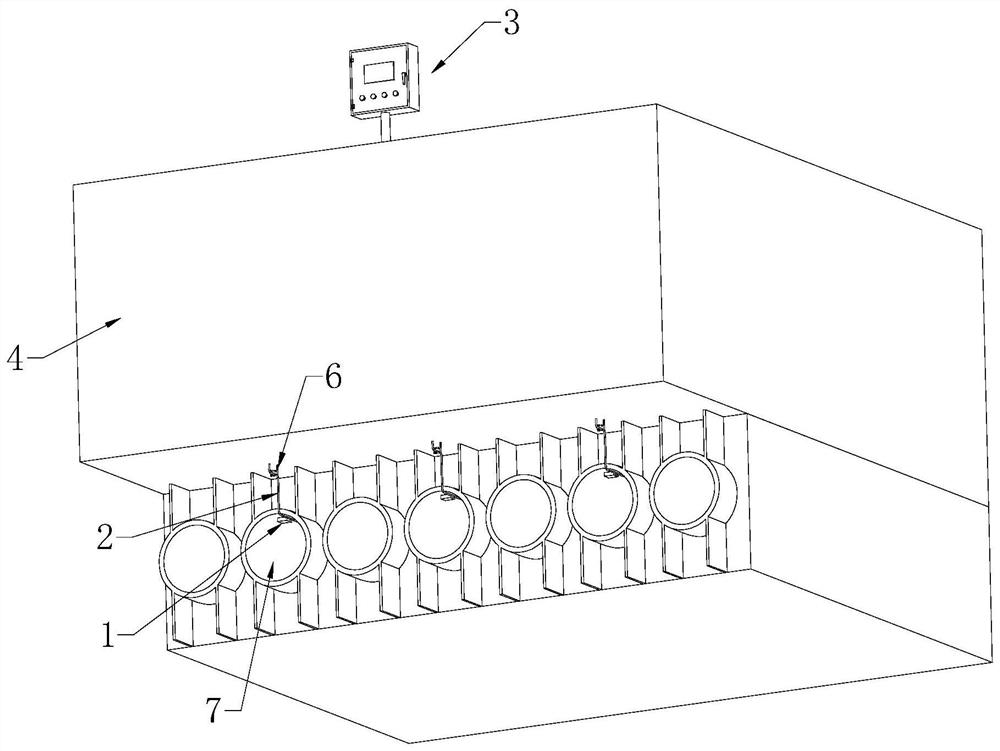

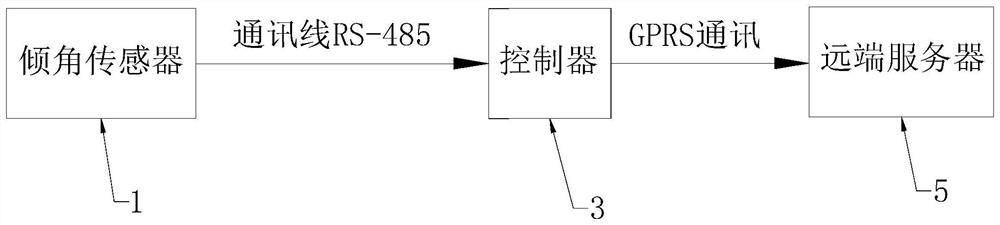

[0043] combine figure 1 and figure 2 As shown, the pipe curtain heave monitoring system applied to the construction of pipe curtain box culverts includes an inclination sensor 1 and a controller 3. The inclination sensor 1 is also called an inclinometer, which is connected in series through a communication line 2 and bonded and fixed in advance. On the inner pipe wall of the monitored steel pipe 7 , the inclination sensor 1 connected in series communicates with the controller 3 through the communication line 2 . The controller 3 is erected and fixed on the concrete base 4 above the pipe curtain, and the controller 3 is connected to the remote server 5 for communication. The inclination monitoring data can be stored in the remote server 5, and the monitoring personnel can directly log in to access the remote server 5 or Access the remote server 5 through the client to obtain the inclination monitoring data, and then know the longitudinal posture changes of the pipe curtain du...

Embodiment 2

[0064] like Figure 9 As shown, the pipe curtain heave monitoring method applied to the construction of pipe curtain box culvert includes the following steps,

[0065] S1. Select the steel pipe 7 at the top of the steel pipe curtain according to the actual working conditions, and clean the inner wall of the selected steel pipe 7 to expose the surface of the steel structure.

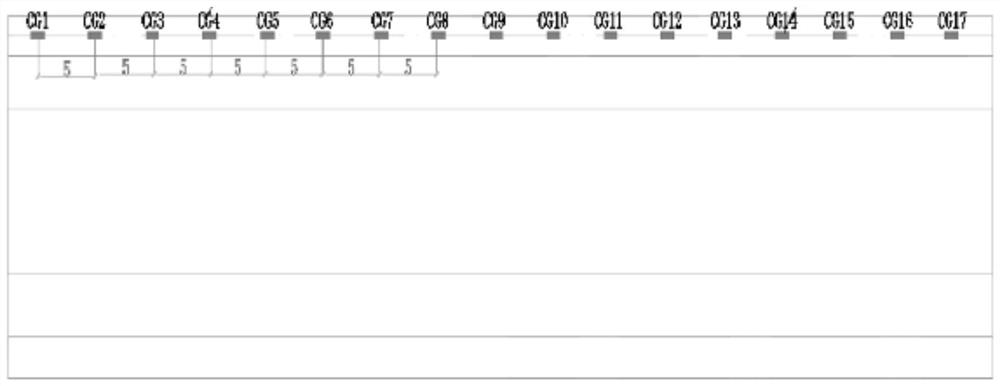

[0066] S2. Utilize the RS-485 communication line 2 to connect 17 inclination sensors 1 in series, the interval between adjacent inclination sensors 1 is 5m, and the inclination sensors 1 connected in series are bonded and fixed to the selected steel pipe 7 along the length direction of the steel pipe 7 top of the pipe wall.

[0067] S3. Set up the controller 3 on the concrete base layer above the steel pipe curtain, and bury the hook 6 on the lower surface of the concrete base 4 in advance. The communication line 2 passes through the steel pipe 7 and hangs it on the corresponding hook 6. The communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com