Scour monitoring system and method for buried pipeline

A monitoring system and pipeline technology, applied in pipeline systems, measuring devices, instruments, etc., can solve the problems of poor monitoring effect, long interval time, and difficulty in covering the entire pipeline along the pipeline, and achieve the effect of improving the monitoring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

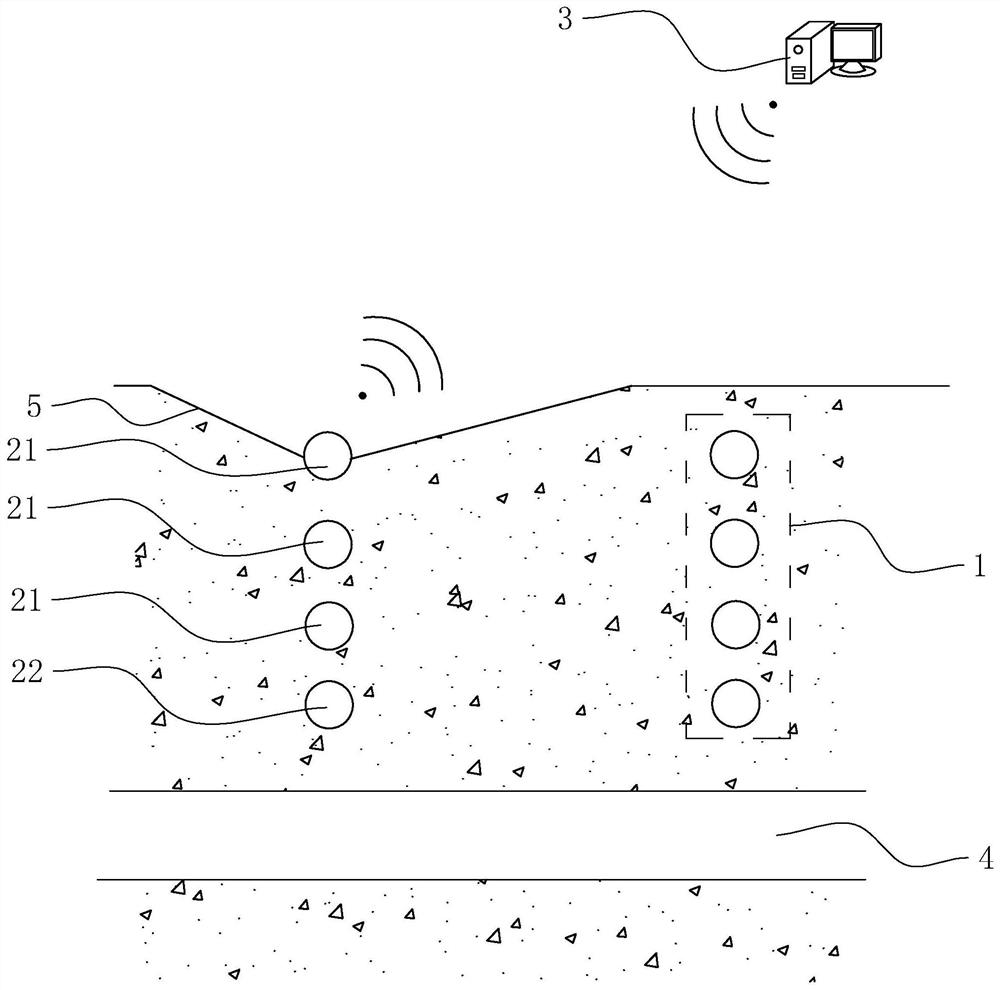

[0050] refer to figure 1 , the system includes multiple sets of monitoring components 1 and a server 3 communicating with the monitoring components 1; multiple sets of monitoring components 1 are buried in the soil layer 5 and located above the pipeline 4, and multiple sets of monitoring components 1 are along the length direction of the pipeline 4 Arranged in sequence. It should be noted that multiple sets of monitoring components 1 do not need to be located directly above the pipeline 4, and sometimes the impact of construction on the pipeline 4 is worried, so the monitoring components 1 need to be properly deviated and placed on one or both sides of the pipeline 4; Or in order to detect problems earlier, the monitoring component 1 can be arranged on the side of the direction where the water flows.

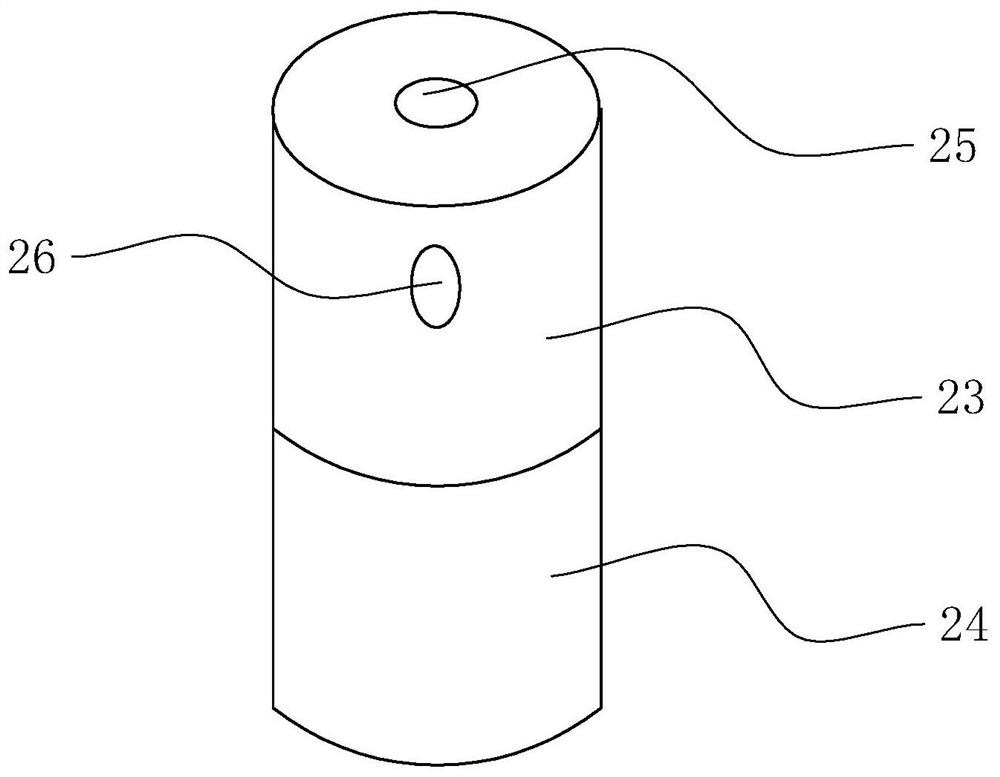

[0051] The monitoring assembly 1 includes a monitoring part 21 and an early warning part 22. The monitoring parts 21 are arranged in multiples and arranged in sequence along th...

Embodiment 2

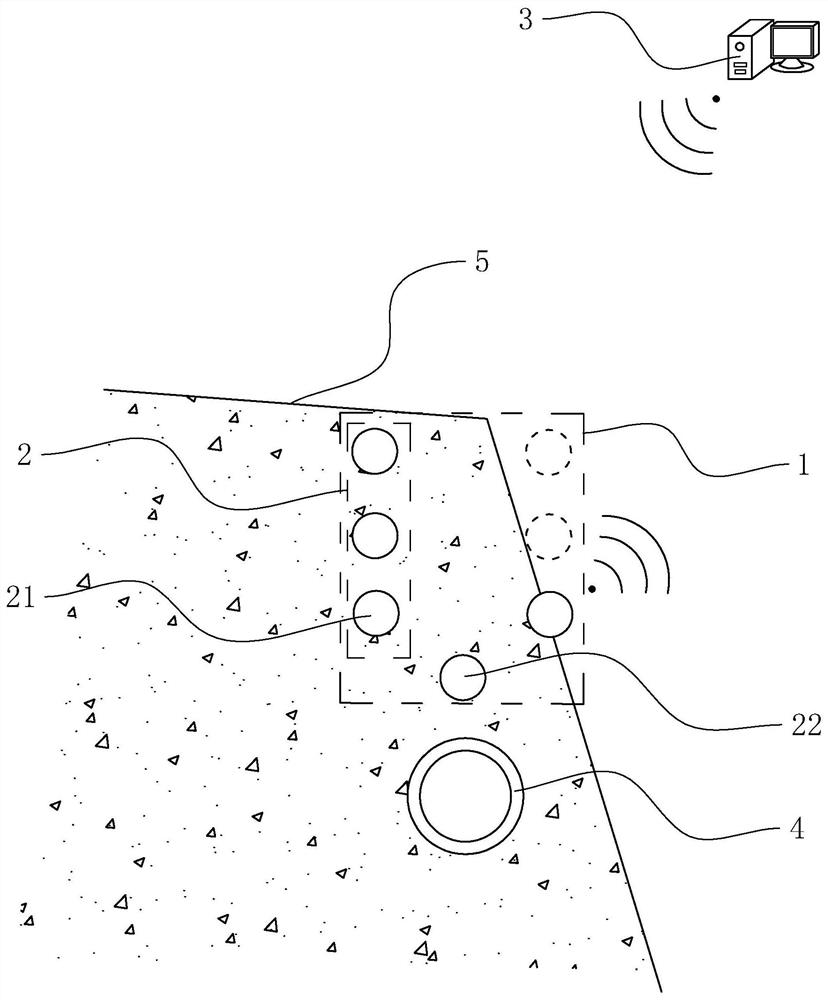

[0062] refer to image 3 , the difference between this embodiment and Embodiment 1 is that each group of monitoring components 1 includes at least two columns of monitoring element groups 2, and this embodiment takes two columns of monitoring element groups as an example, and each column of monitoring element groups 2 includes a plurality of edge For the monitoring elements 21 arranged in the vertical direction, the connection direction of the two rows of monitoring element groups 2 is perpendicular to the extension direction of the pipeline 4 , and the two rows of monitoring element groups 2 are located above the two sides of the pipeline 4 .

[0063] The implementation principle of embodiment 2 is: when the system is applied to the monitoring of slope water damage, the water flow erosion may cause the slope to collapse, forming a nearly 90-degree fracture surface. In this case, the system in embodiment 1 is due to The monitoring part 21 and the early warning part 22 are loca...

Embodiment 3

[0065] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that an early warning accessory 27 is provided between two adjacent groups of monitoring components 1 , and the early warning accessory 27 is also located above the pipeline 4 . The structure of the early warning accessory 27 is the same as that of the early warning accessory 22 , and the embedding distance between the early warning accessory 27 and the pipeline 4 is also equal to the embedding distance between the early warning accessory 22 and the pipeline 4 .

[0066] The implementation principle of Embodiment 3 is as follows: the purpose of setting up the early warning accessory 27 is to increase the early warning range along the length direction of the pipeline 4 and help the staff to know the surrounding conditions of the pipeline 4 more timely and comprehensively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com