Automobile full-bridge air tightness detection tool

An air-tightness detection and automotive technology, which is used in fluid-tightness testing, measuring devices, and liquid-tightness measurement using liquid/vacuum degree. The effect of ensuring the quality of the full bridge, ensuring stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

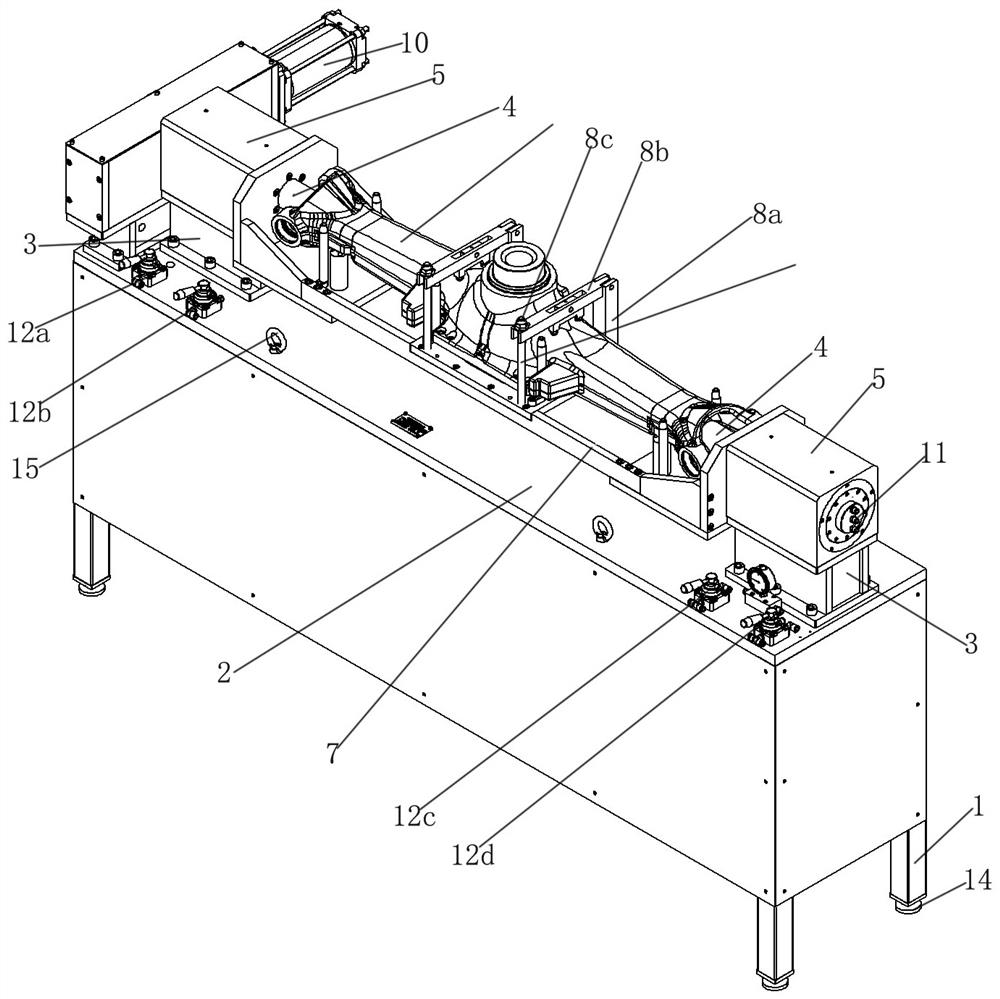

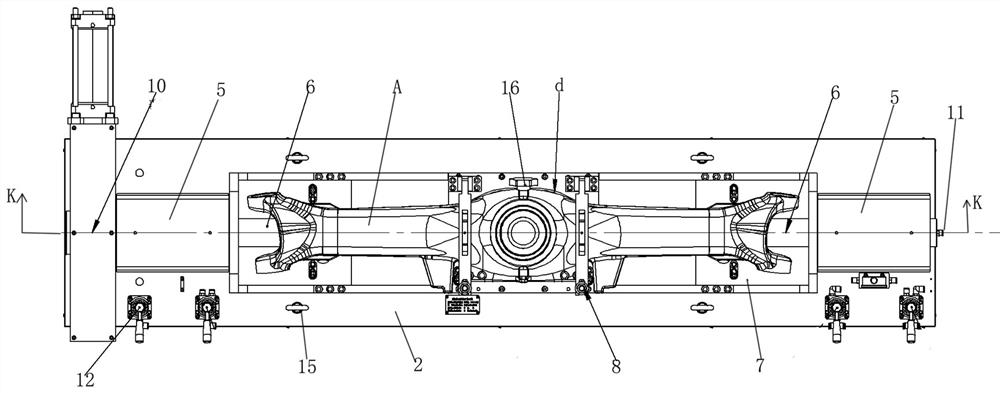

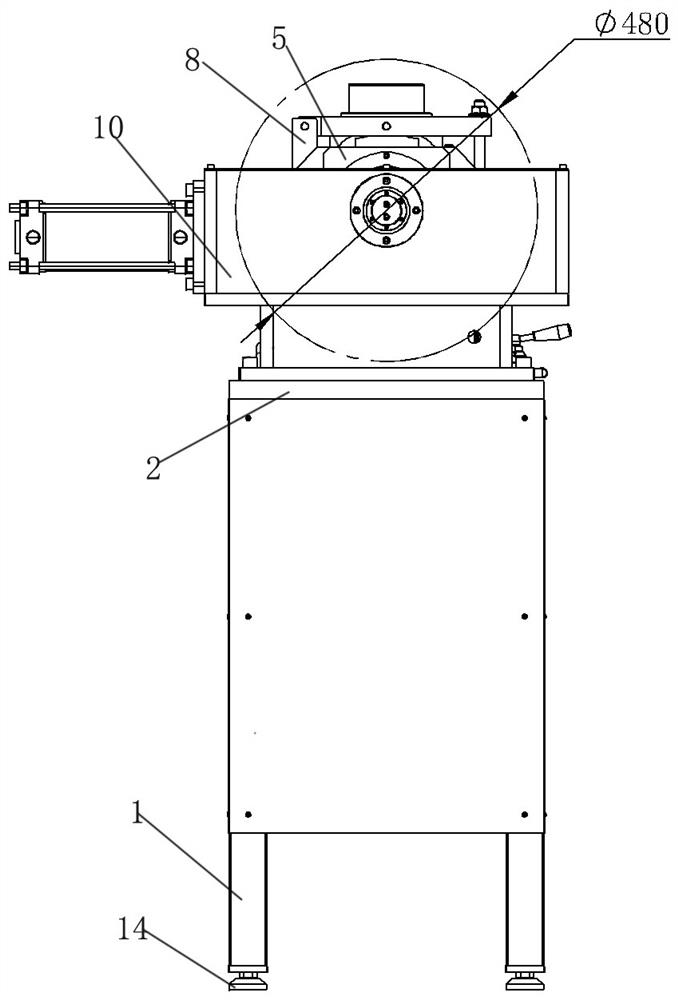

[0029] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , in the figure, 1-supporting leg, 2-operating platform, 3-fixed seat, 4-clamping cylinder, 5-bearing seat, 6-piston rod, 7-rotating frame, 8-manual limit frame (pole 8a , cross bar 8b, bolt 8c), 9-hydraulic positioning pin, 10-cylinder turning mechanism, 11-pipeline, 12-operating switch, 13-sealing ring, 14-foot, 15-lifting ring, 16-movable plug, 17-extended workpiece; A-product, B-internal chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com