Electric power engineering field intelligent management system

A power engineering and management system technology, applied in the field of power engineering, can solve problems such as many unsafe factors, poor reliability, and difficult safety management of power line foundation construction, and achieve flexible data operation and upload, good durability and reliability, The effect of inspection data visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The application will be described in further detail below in conjunction with the accompanying drawings.

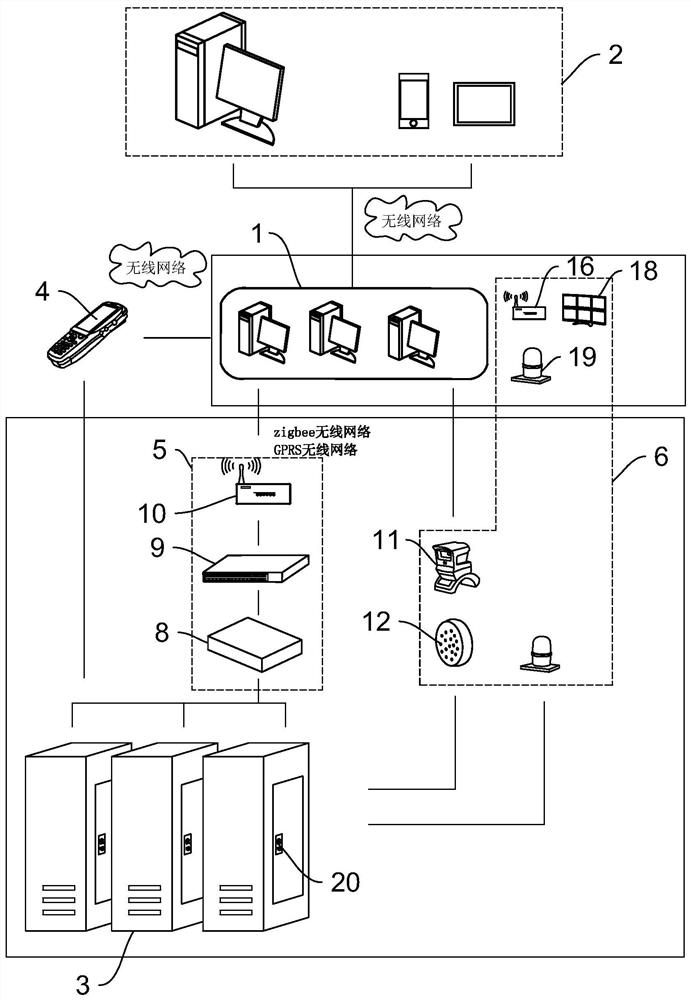

[0040] The embodiment of the present application discloses an on-site intelligent management system for electric power engineering. refer to figure 1 , including the data server 1 installed on the workstation, the supporting service management terminal 2, the power equipment 3 installed on the construction site, the patrol inspection terminal 4 wirelessly connected to the supporting service management terminal 2, the equipment operation monitoring subsystem 5, and the on-site visual monitoring subsystem6.

[0041] This system is based on the B / S structure framework. The data server 1 uses an FTP server or a Web server, and the supporting service management terminal 2 uses multiple PC terminals and multiple portable intelligent mobile terminals. It has the functions of query, update, transaction Management, indexing, cache, query optimization, security and multi-use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com