Automatic rapid treatment water tank for domestic water

A technology for domestic water and water tank treatment, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sewage treatment equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

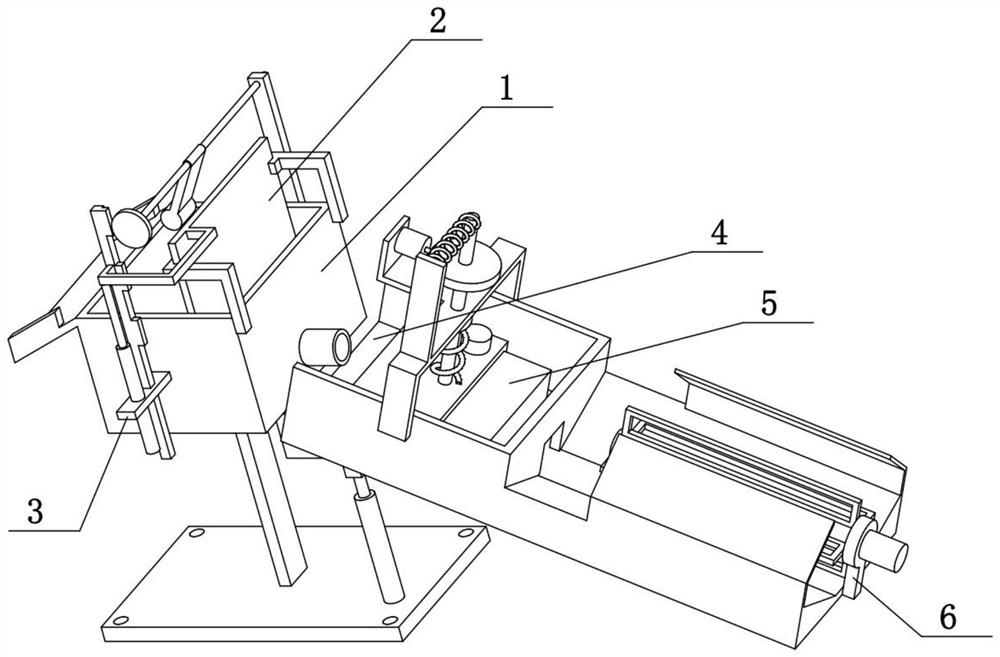

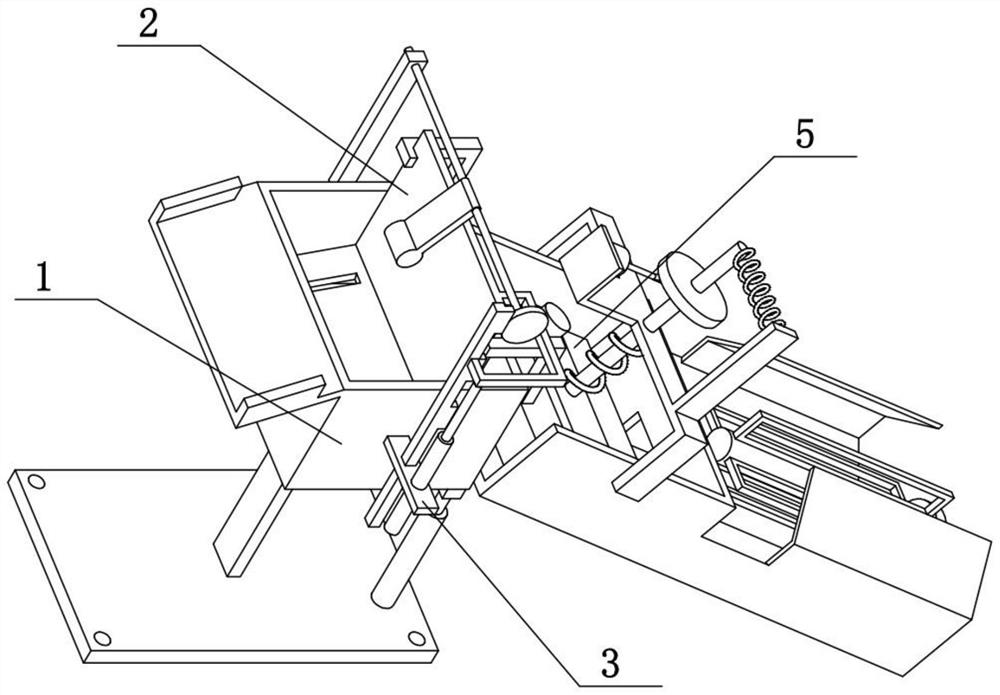

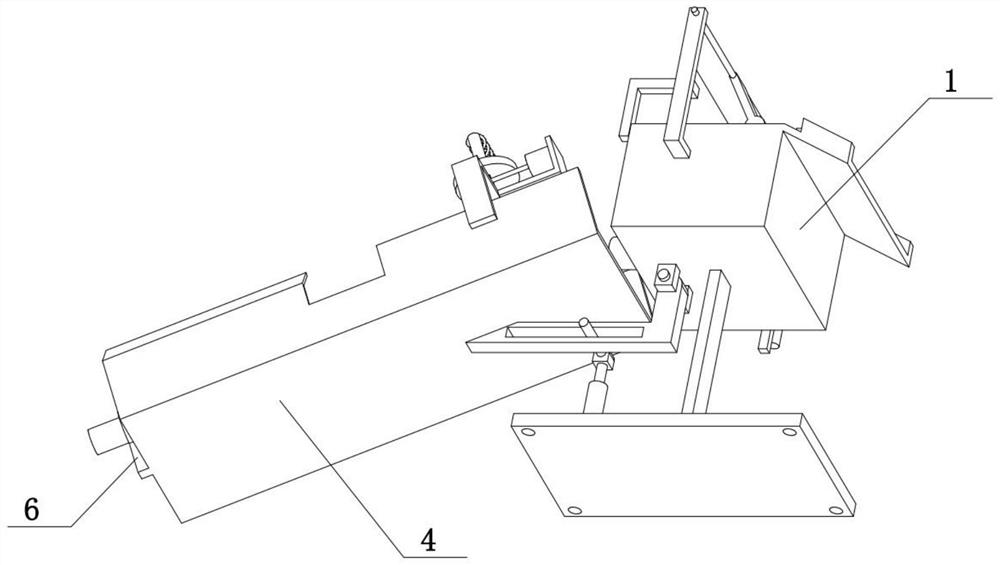

[0032] Combine below Figure 1-11 Describe this embodiment, the present invention relates to a water treatment equipment, more specifically a water tank for automatic and rapid treatment of domestic water, including a water tank 1, a bracket 101, a diagonal flow plate 102, a liquid outlet pipe 107, a vertical baffle 2 and an inclined filter Plate 201, the present invention can perform rapid filtration treatment on domestic water.

[0033] The upper right side of the water tank 1 is fixedly connected with a diagonal flow plate 102, the front and rear ends of the water tank 1 are fixedly connected with brackets 101, the lower right side of the water tank 1 is fixedly connected with a liquid outlet pipe 107, and the vertical baffle 2 slides vertically Connected between the two brackets 101, the right part of the inclined filter plate 201 is fixedly connected to the lower part of the vertical baffle plate 2, and the left side of the inclined filter plate 201 is attached to the inn...

specific Embodiment approach 2

[0035] Combine below Figure 1-11To illustrate this embodiment, the water tank for automatic and rapid treatment of domestic water also includes a convex seat 3, an electric push rod 301, a vertical slide bar 302 and a folding bar 309, the front side of the water tank 1 is fixedly connected with the convex seat 3, and the vertical slide bar 302 is vertical Slidingly connected to the convex seat 3, one end of the folding rod 309 is fixedly connected to the top of the vertical slide bar 302, the other end of the folding rod 309 is fixedly connected to the top of the vertical baffle plate 2, and the convex seat 3 is fixedly connected to the electric push rod 301 , the movable end of the electric push rod 301 is fixedly connected to the folding rod 309 . When the electric push rod 301 stretches, it can drive the folding rod 309 and the vertical slide bar 302 to slide upwards, and then the folding rod 309 controls the vertical baffle plate 2 and the inclined filter plate 201 to mov...

specific Embodiment approach 3

[0037] Combine below Figure 1-11 To illustrate this embodiment, the automatic and rapid domestic water treatment water tank also includes a smashing block 305, a connecting column 306, a bracket 307 and a fixed shaft 308, the rear side of the water tank 1 is fixedly connected with a bracket 307, and the top of the smashing block 305 is fixedly connected with a connecting Column 306, the top of connecting column 306 is fixedly connected with fixed shaft 308, the rear end of fixed shaft 308 is connected to the top of support 307 in rotation, smashing block 305 is positioned at the left side of vertical baffle plate 2. The connecting column 306 and the smashing block 305 can be rotated on the support 307 with the axis of the fixed shaft 308 as the axis through the fixed shaft 308, and then the smashing block 305 is rotated and lifted and smashed on the vertical baffle 2 to vibrate the vertical baffle 2 , and then vibrate the inclined filter plate 201 to facilitate the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com