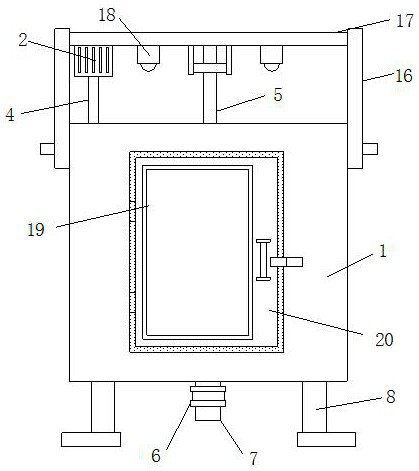

Efficient wastewater filtering device for machining

A mechanical processing, high-efficiency filtration technology, applied in the direction of filtration separation, moving filter element filters, separation methods, etc., can solve the problems of inconvenient cleaning and low filtration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

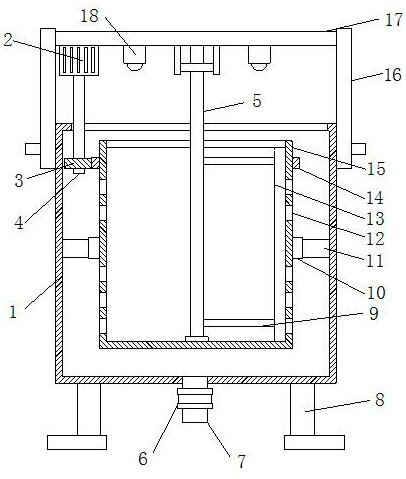

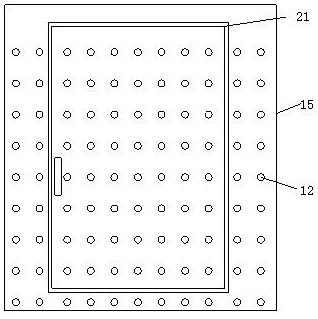

[0020] Embodiment: Firstly, waste water is poured into the filter barrel 15, and then the waste water can be filtered through the filter through hole 12, and the reduction motor 2 is started, and the reduction motor 2 drives the main gear 3 to rotate through the drive shaft 4, and the rotating main gear 3. By driving the filter barrel 15 to rotate from the gear 14, the rotating filter barrel 15 drives the waste water to rotate, and the waste water does a centrifugal motion, thereby improving the filtering effect of the filter through hole 12 on the waste water, and when the filter barrel 15 is rotating, the slide plate can be attached to the The impurities on the inner wall of the filter hole and the inner surface of the second cleaning door panel 21 are scraped off, and the inside of the device shell 1 and the inside of the filter barrel 15 can be cleaned through the first cleaning port and the second cleaning port. By opening the switch valve 6, Then the waste water in the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com