Facing sand screening equipment for water permeable bricks

A technology of screening equipment and permeable bricks, which is applied in the direction of screening, solid separation, grille, etc., and can solve the problems of easy blockage of the screen cylinder by soil blocks, increase of labor intensity, and influence of surface sand screening efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

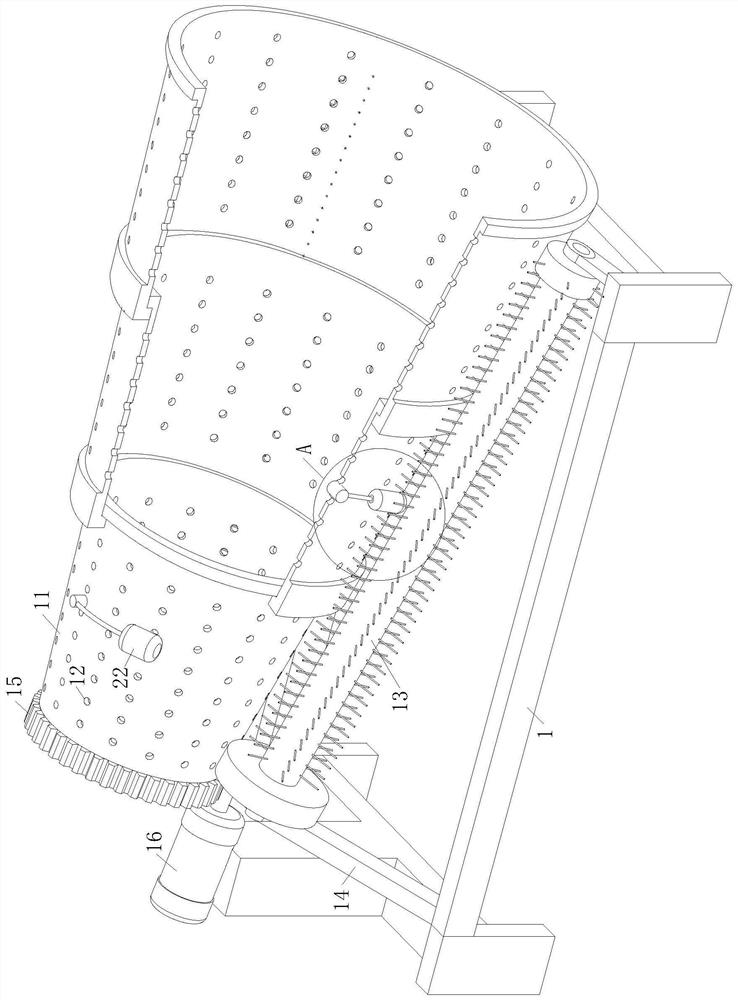

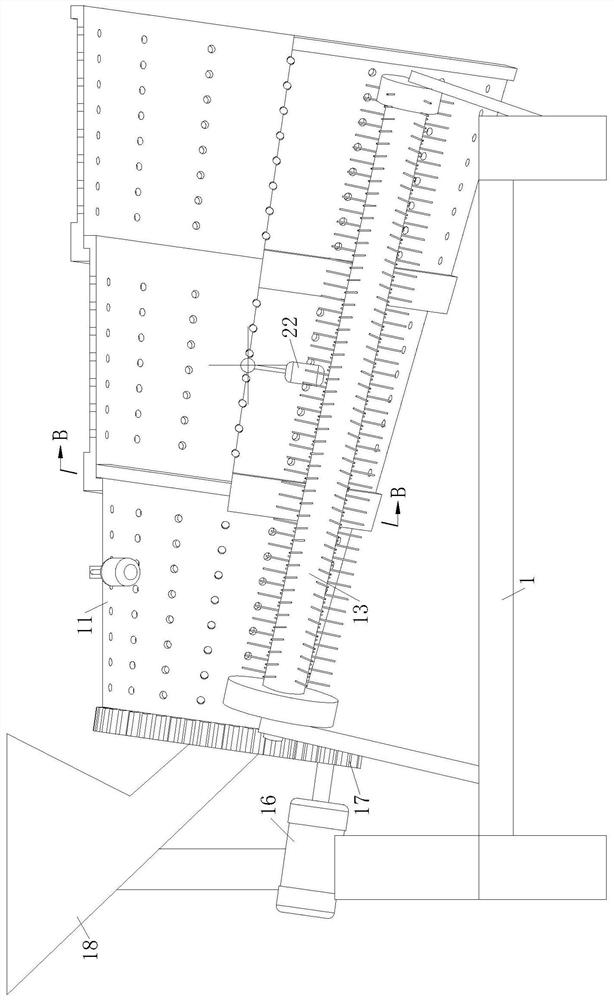

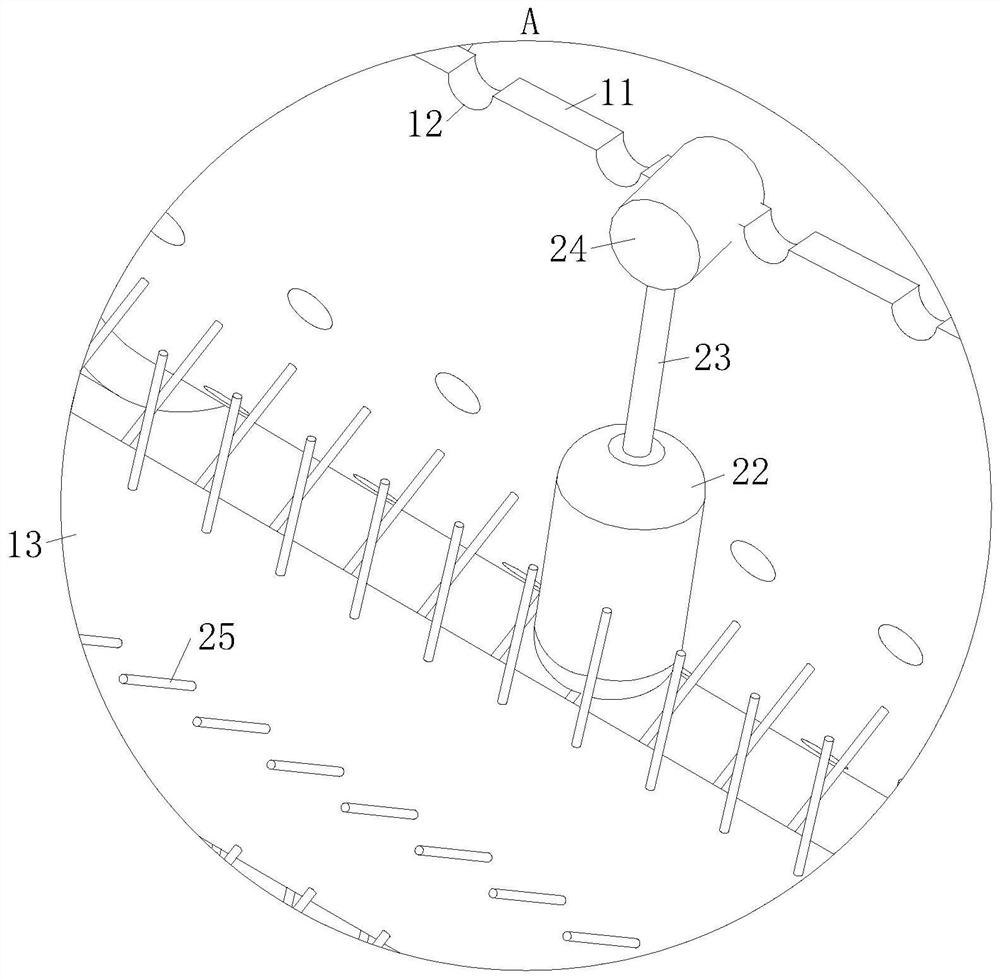

[0025] As an embodiment of the present invention, the sieve cylinder 11 is conical and its diameter gradually increases towards the direction away from the feed hopper 18; the rotational resistance at the joint of adjacent sieve cylinders 11 is reduced by the conical sieve cylinder 11, Further increase the vibration of the screen cylinder 11 to increase the screening efficiency; through the tapered screen cylinder 11, the surface sand in the screen cylinder 11 will continuously fall and move naturally to the lower end of the screen cylinder 11 with its own weight during the rotation of the screen cylinder 11. Then increase the discharge efficiency of impurities with larger particles after the screening of surface sand, accelerate the discharge of soil clods, reduce the blockage of sieve holes 12, and simultaneously make the surface sand at the junction of the adjacent sieve cylinder 11 flow downward quickly, reducing the inflow of surface sand The connection of adjacent screen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com