New energy automobile driving motor suspension structure

A technology for new energy vehicles and driving motors, which is applied in the direction of power devices, electromechanical devices, and electric power devices, and can solve problems such as poor installation stability, vibration, and inconvenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

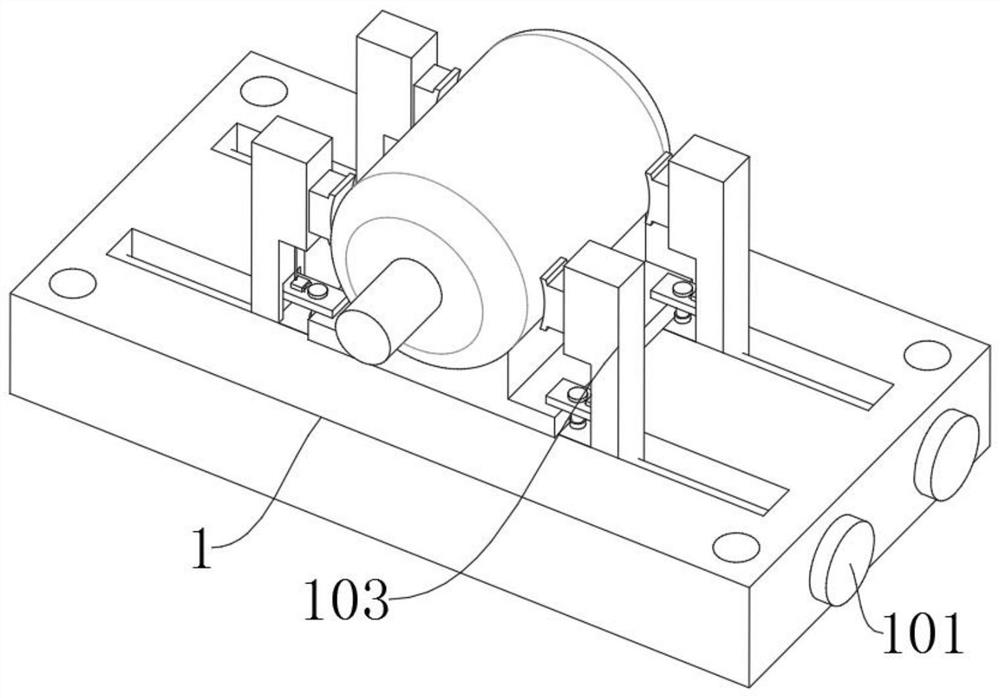

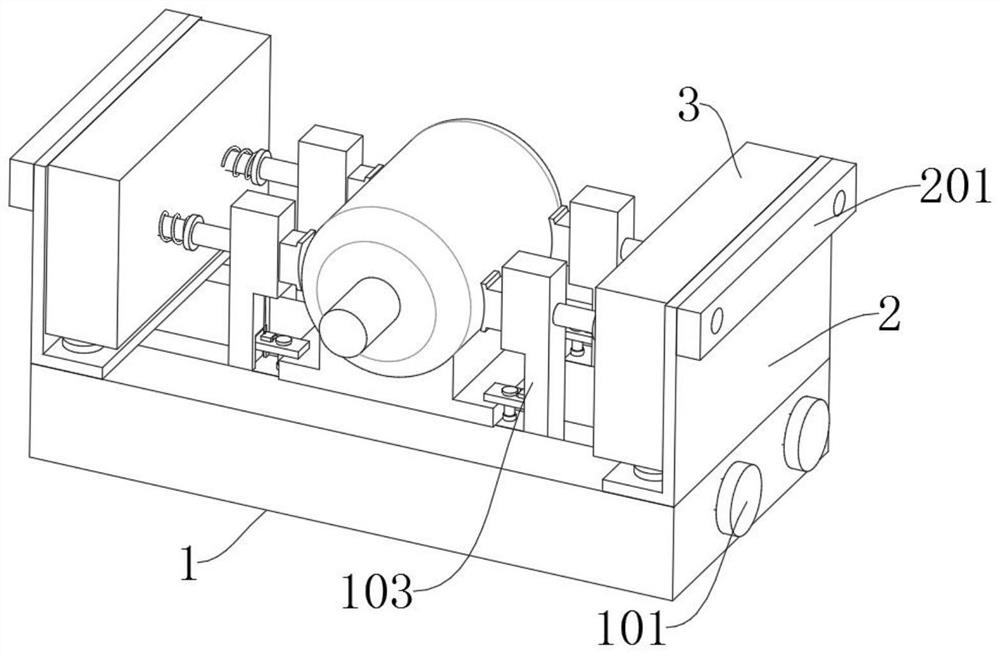

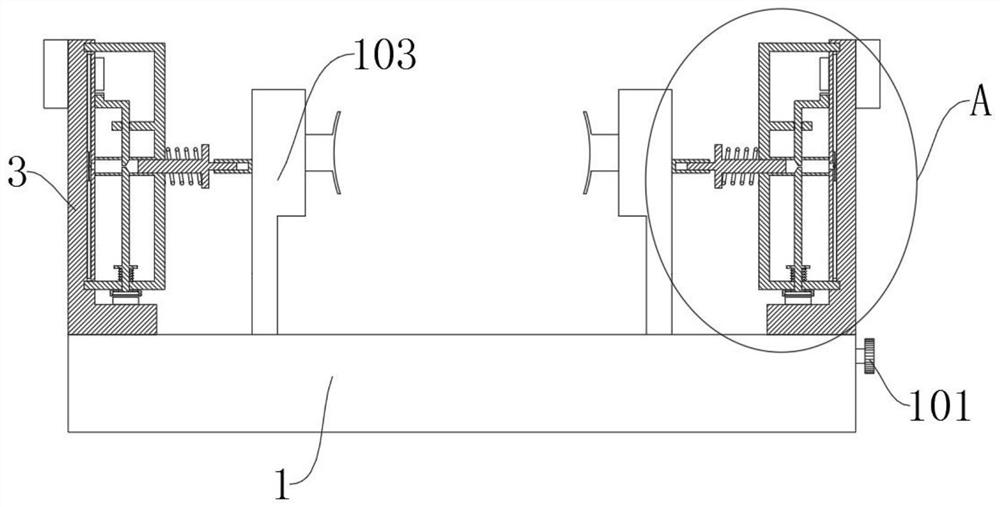

[0032] refer to Figure 1-9 , a new energy vehicle drive motor suspension structure, including a frame longitudinal beam 201, and also includes: a mounting base 1; a rotating screw 101, rotatably connected to the mounting base 1; a clamping plate 103, symmetrically arranged in two groups, It is used to fix the drive motor, and is connected with the threaded screw rod 101; wherein, the directions of the threads on the two sets of clamping plates 103 are opposite; It is connected with the installation base 1 through the lower bolt 203; the protective cover 3 is inserted on the suspension frame 2; the sliding rod 301 is slidably connected to the protective cover 3 and attached to the clamping plate 103; the sliding spring 302 is sleeved on the On the sliding rod 301, both ends are respectively fixedly connected to the sliding rod 301 and the protective cover 3; the sliding rod 4 is slidably connected to the protective cover 3, and one end is placed in the protective cover 3; One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com