Air port converging mechanism of backrest ventilating fan and automobile seat

A ventilation fan and tandem technology, which is applied to vehicle seats, seat heating/ventilation devices, vehicle components, etc., can solve the problems of long air paths, unfavorable seat ventilation, and high wind damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

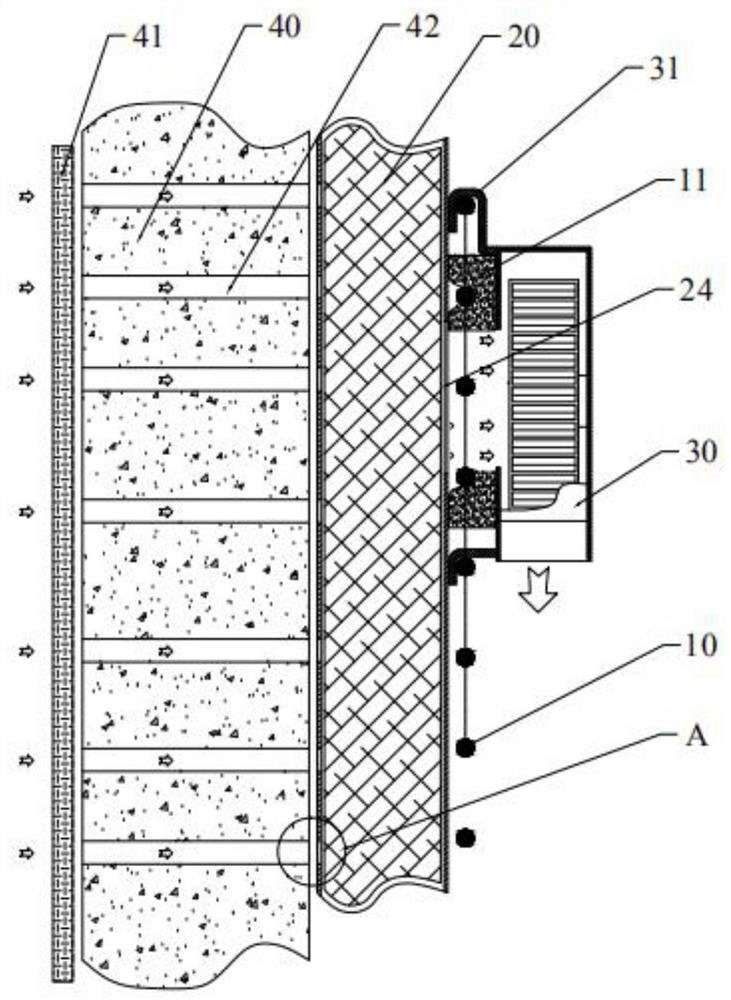

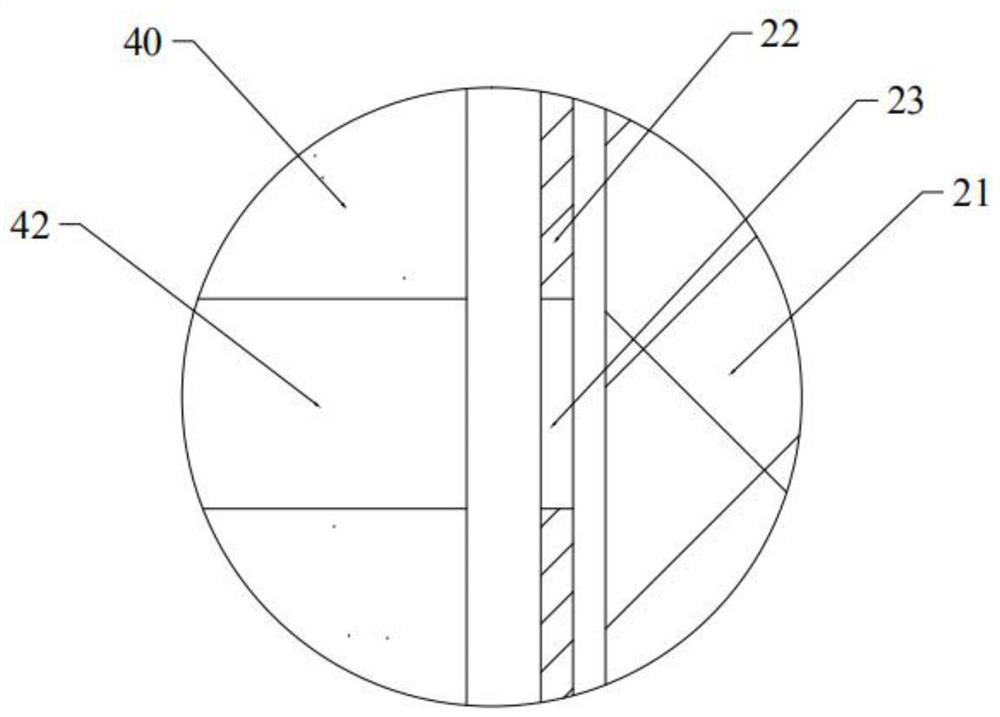

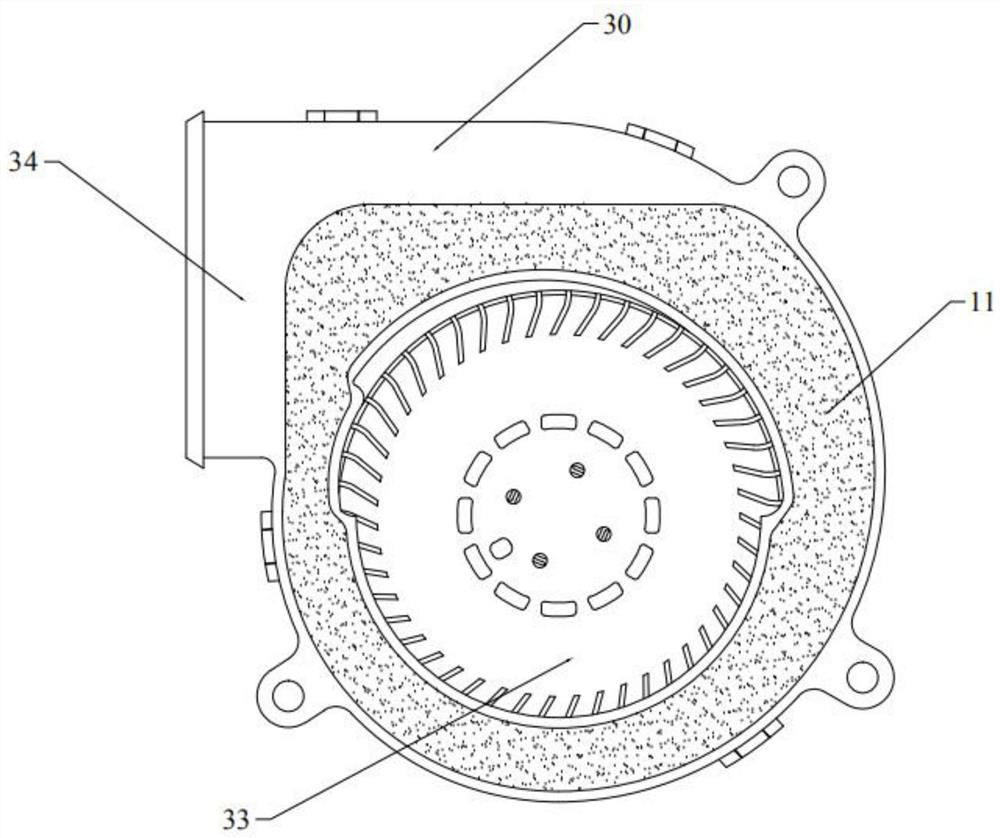

[0030] Please refer to figure 1 and figure 2 , the present embodiment provides a tuyere confluence mechanism of a backrest ventilation fan, including a frame wire spring frame 10; one side of the frame wire spring frame 10 is provided with an air guide structure, and the other side is provided with a ventilation fan 30; In the embodiment, the air guide structure is an air guide bag 20. In other embodiments of the present application, the air guide structure can also be set to any of the following structures: a sealing layer plus a foamed internal channel structure, and a sealed air guide inside the sealing layer. layer (commonly used three-dimensional knitted mesh cloth or a plastic plate with protrusions), or a foaming structure can be provided on the outside of the side of the air guide bag surface cover with the total air path interface 24, on the foaming structure A through hole is opened to communicate with the main air path interface and the air inlet or air outlet of ...

Embodiment 2

[0036]This embodiment provides another tuyere confluence mechanism of the backrest ventilation fan. The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that one end of the first flexible wind-blocking cushion layer 11 is fixedly connected to On the side where the wind guide bag 20 has the total air path interface 24, since the first flexible wind blocking cushion layer 11 is a compressible elastic material, it can avoid the steel wire of the frame wire spring frame 10 at a fixed point. The free end of a flexible wind-blocking cushion layer 11 can pass through the gap between the adjacent steel wires and be directly compressed with the ventilation fan 30, and can also be partially compressed on the steel wires to undergo elastic deformation, that is, it is bonded and merged with the steel wires. In the depressed state, the other part is compressed on the ventilation fan 30 and undergoes a small elastic deformation, and because th...

Embodiment 3

[0038] Please refer to image 3 , this embodiment provides another tuyere confluence mechanism of the backrest ventilation fan. The similarities between this embodiment and Embodiment 1 will not be described in detail. There is also a second flexible wind-blocking cushion layer 12 in between; the second flexible wind-blocking cushion layer 12 is a compressible elastic wind-blocking material, and a second air path hole corresponding to the first air path hole is opened on it; One end of the second flexible wind-blocking cushion layer 12 is fixedly connected to the side of the air-guiding bag 20 with the main air-way interface 24, and the other end is used for extrusion-tight fit with the first flexible wind-blocking cushion layer 11 , that is, the first flexible wind-blocking cushion layer 11 and the second flexible wind-blocking cushion layer 12 are disposed opposite to each other between the ventilation fan 30 and the wind guide bag 20 . In this embodiment, one end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com