Clothes making hanging system and rail changing control method thereof

A control method and hanging technology, which are applied to conveyor control devices, conveyor objects, conveyors, etc., can solve the problems of slow clothing production, long time consumption, affecting system work efficiency, etc., so as to save the transition time and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

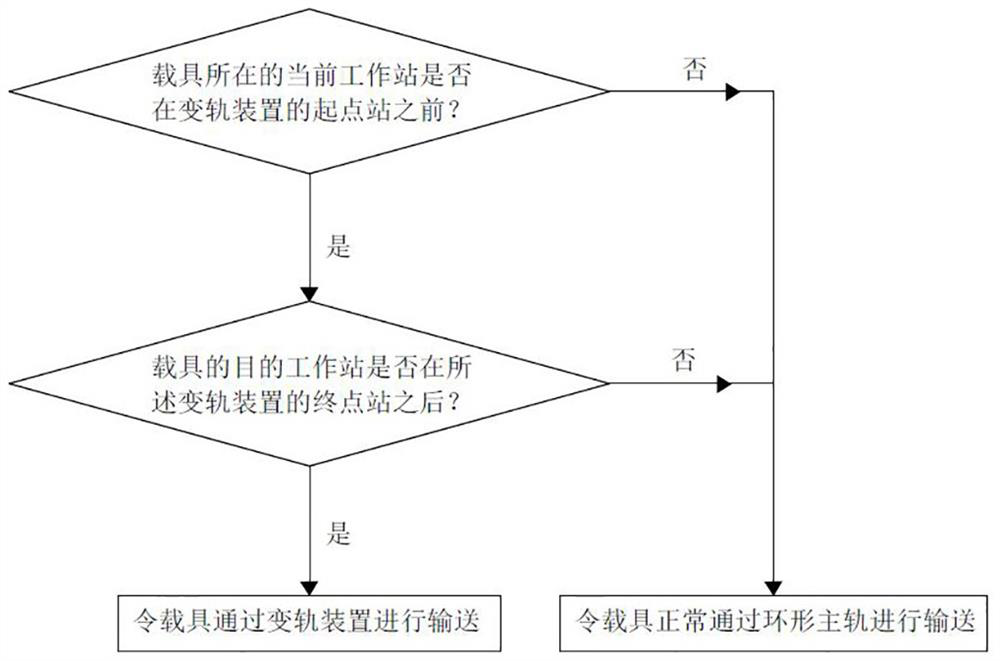

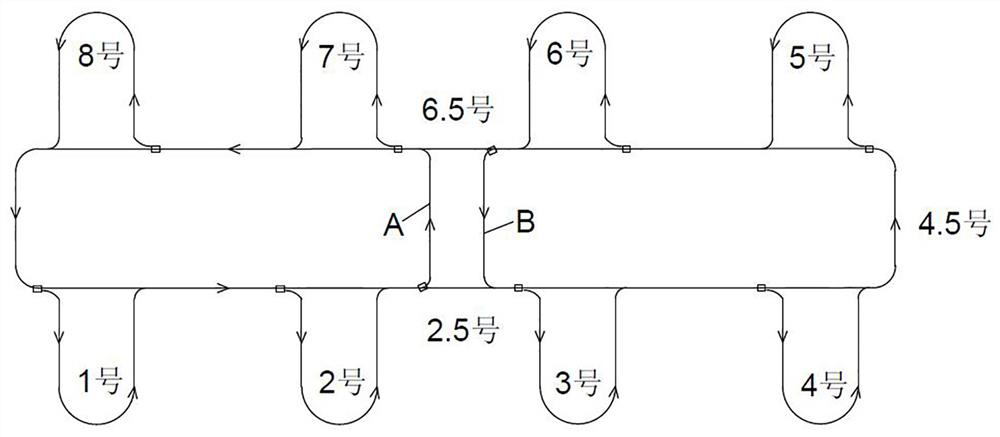

[0024] A track change control method for a garment hanging system, the garment hanging system includes a ring-shaped main rail, a carrier, and a plurality of workstations arranged along the ring-shaped main rail; Track change device, described track change control method comprises:

[0025] The current workstation where the carrier is located and the destination workstation are on the opposite side track of the ring main rail, and the current workstation where the carrier is located and the starting point of the track changing device are on the same side track of the ring main rail, and the destination workstation of the carrier When the terminal station of the track changing device is on the same side track as the circular main rail, if the current workstation where the carrier is located is before the starting station of the track c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com