The Method of Losing Electricity and Dissipating Tension in Large Vertical Annealing Furnace

A vertical annealing furnace and annealing furnace technology, applied in the field of iron and steel manufacturing, can solve the problems of large frictional resistance of strip steel, inability to compensate strip steel, long strip steel, etc., and achieve the effect of avoiding transitional deformation and broken strip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

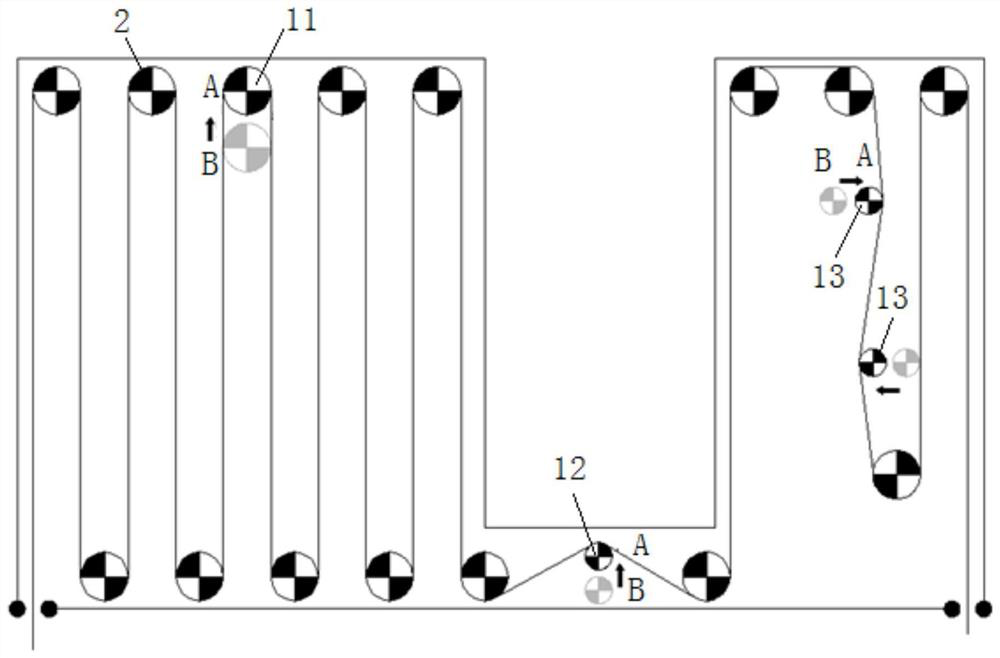

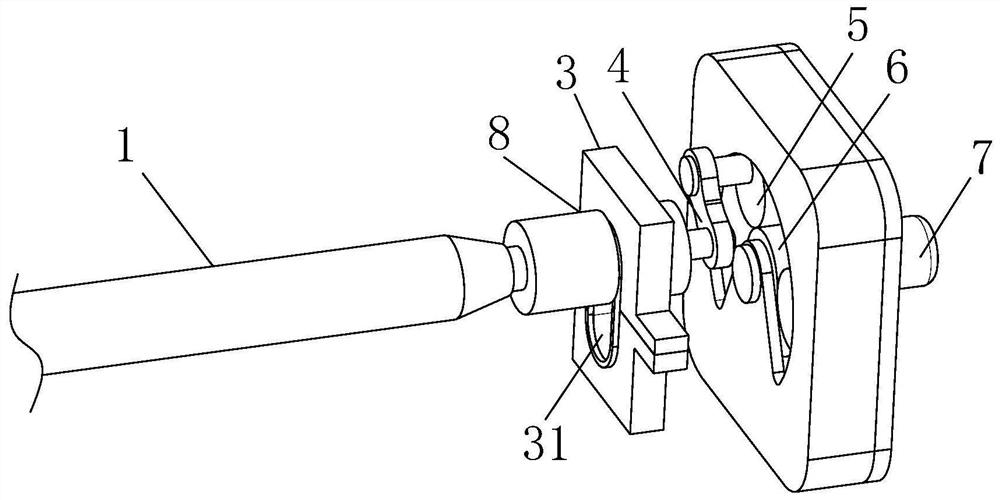

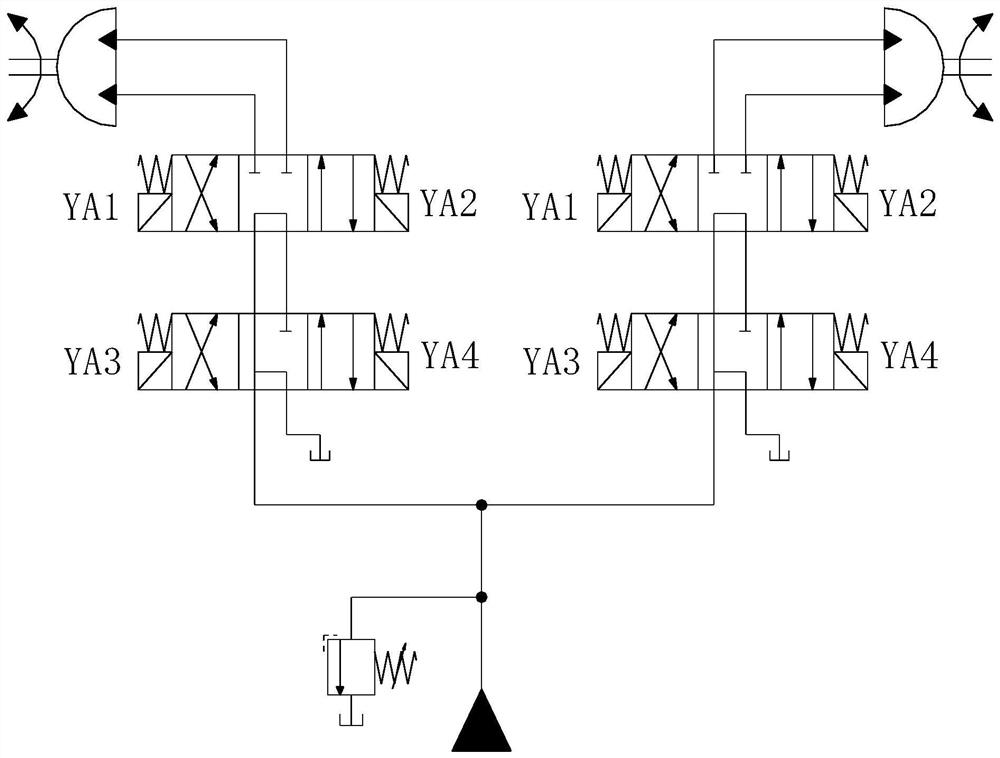

[0033] Usually, see Figure 1 to Figure 8 , the annealing furnace is provided with several furnace rolls for tensioning the steel strip during annealing. In the method of power loss and tension elimination of the large vertical annealing furnace of the present invention, the furnace rolls are divided into fixed rolls 2 and movable moving rolls 1. The fixed and moving here refer to the fixed and movable axis positions of the furnace rollers respectively. Both the fixed roller 2 and the moving roller 1 can rotate. When the power is on, the moving roller 1 is controlled to remain at Tensioning position A for tensioning the steel strip; after power failure, unlock the moving roller 1 and move the moving roller 1 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com