Atmospheric sampling instrument for environmental monitoring

An atmospheric sampler and environmental monitoring technology, applied in sampling devices, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problems of inconvenient movement of the atmospheric sampler and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

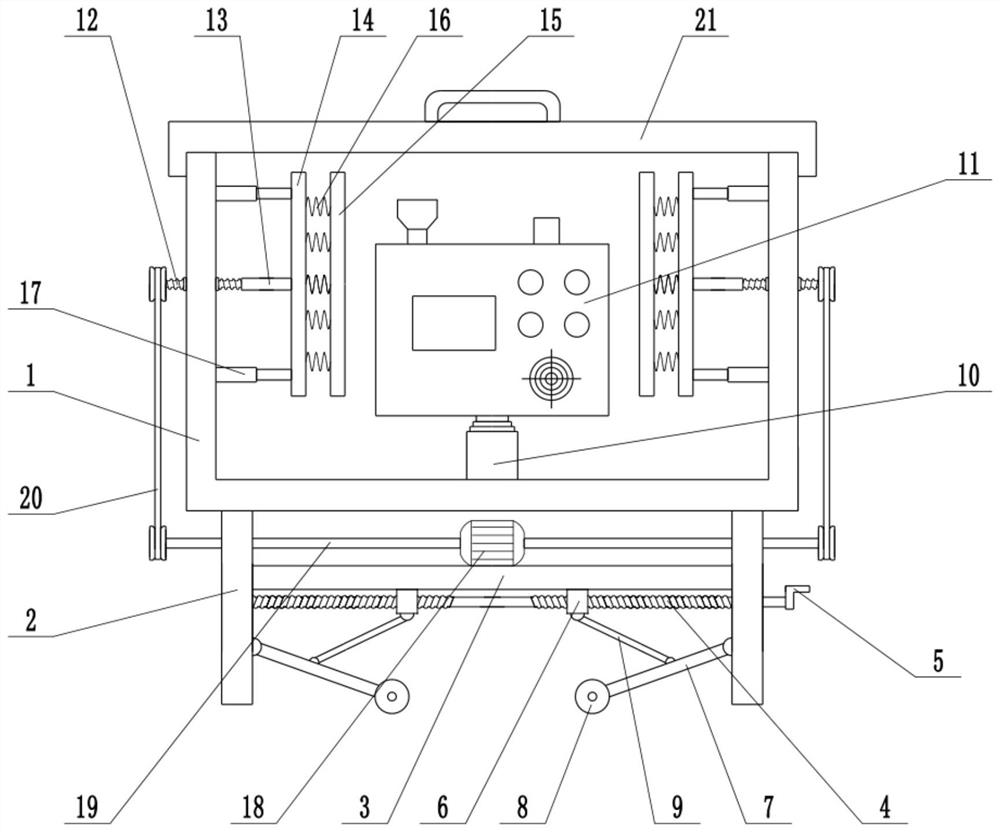

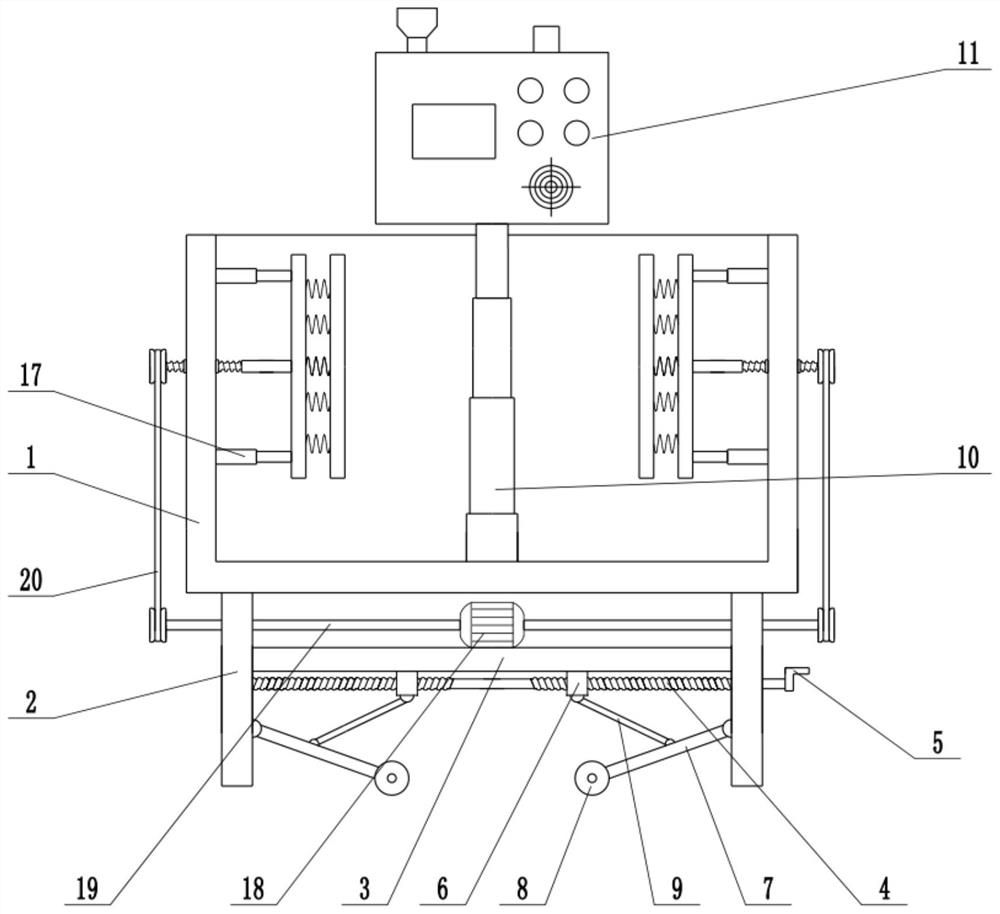

[0023] see Figure 1-3 , in an embodiment of the present invention, an atmospheric sampler for environmental monitoring includes a housing 1, a support plate 2, a sampler body 11 and a movable cover 21, the bottom of the housing 1 is fixedly connected with a support plate 2, and there are two support plates 2 , left and right symmetrically arranged, the bottom of the shell 1 is provided with a fixed plate 3, the left and right ends of the fixed plate 3 are respectively fixedly connected with the support plate 2, the inside of the shell 1 is equipped with a telescopic mechanism 10, and the telescopic mechanism 10 is an electro-hydraulic telescopic cylinder. The top of the mechanism 10 is fixedly connected with the sampler body 11, which controls the expansion and contraction of the telescopic mechanism 10, which can drive the sampler body 11 to move up and down, adjust the height of the sampler body 11, and use the sampler body 11 to perform atmospheric sampling operations. The...

Embodiment 2

[0025] On the basis of Embodiment 1, a moving mechanism is installed on the bottom of the fixed plate 3, and the moving mechanism includes a two-way screw rod 4, a slide block 6, a movable rod 7, a universal wheel 8 and a connecting rod 9, and the bottom of the fixed plate 3 is provided with The two-way screw rod 4, the left and right ends of the two-way screw rod 4 are respectively connected to the support plate 2 in rotation, the end of the two-way screw rod 4 is equipped with a crank handle 5, and the two-way screw rod 4 is covered with a slider 6, and the slider 6 has a total of Two, arranged symmetrically left and right, the slider 6 is threadedly connected with the two-way screw rod 4, the upper surface of the slider 6 is slidably connected with the bottom of the fixed plate 3, the side wall of the support plate 2 is hinged with a movable rod 7, and the movable rod 7 The lower end is equipped with a universal wheel 8, the lower surface of the slider 6 is hinged with a con...

Embodiment 1、 Embodiment 2

[0026] In conjunction with Embodiment 1 and Embodiment 2, the working principle of the present invention is: when the atmospheric sampling operation is required, the movable cover 21 is removed, the biaxial motor 18 is controlled to reverse, and the buffer plate 15 is out of contact with the sampler body 11, Control the expansion of the telescopic mechanism 10 to drive the sampler body 11 to move upwards, so that the sampler body 11 is lifted from the shell 1 to facilitate the atmospheric sampling operation. After the sampling operation is completed, the control telescopic mechanism 10 is shortened to make the sampler body 11 re- Return to the housing 1, start the biaxial motor 18, drive the drive shaft 19 to rotate, and then drive the screw rod 12 to rotate through the transmission belt 20, drive the clamping plate 14 to move laterally, and make the buffer plate 15 contact the side wall of the sampler body 11 , use the buffer plate 15 to clamp the sampler body 11 to keep the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com