Dry sludge incineration and feeding device for textile wastewater treatment

A technology for drying sludge and feeding device, which is applied to incinerators, combustion methods, combustion types, etc., and can solve the problems of affecting sludge incineration treatment efficiency, long sludge incineration time, and large amount of feeding at one time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

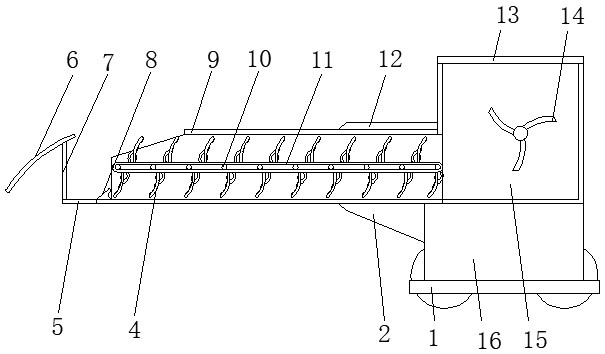

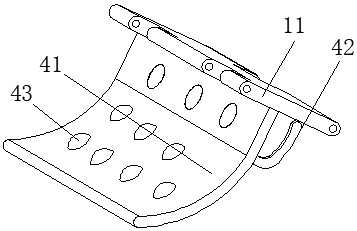

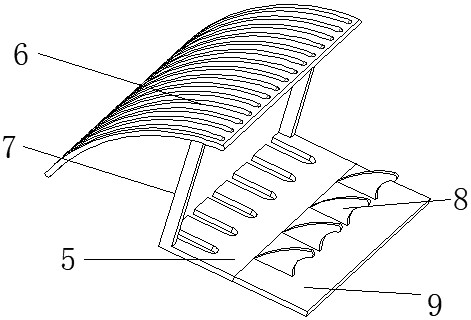

[0028] refer to Figure 1-3 , a dry sludge incineration feeding device for textile sewage treatment, comprising a base 1, a support frame 16 is fixedly installed on the top of the base 1, and a feed box 15 is fixedly installed on the top of the support frame 16, and the top of the support frame 16 A feed pipe 9 with a rectangular structure is fixedly installed between the side of the feed box 15, and a plurality of conveying rollers 10 are mounted on the inside of the feed pipe 9 through bearings, and the outer sides of the conveying rollers 10 are sleeved with conveying rollers. Chain plate 11, the outer surface of conveying chain plate 11 is fixedly equipped with elastic scraping mechanism 4, the inside of support frame 16 is fixedly installed with main drive motor, and the output shaft of main drive motor is connected with transmission roller 10 through chain, One end of the material tube 9 is fixedly equipped with a plurality of stoppers 8 of arc-shaped structure, and the ...

Embodiment 2

[0037] refer to Figure 2-5 , a dry sludge incineration feeding device for textile sewage treatment. Compared with Example 1, the outer side of the feeding pipe 9 is sleeved with a sealing ring mechanism 3, and the end of the sealing ring mechanism 3 is provided with A sealing ring 32 extending to the interior of the incinerator;

[0038] The sealing ring mechanism 3 includes a plugging plate 31 adapted to the feed interface of the incinerator, and the inner wall of the plugging plate 31 is provided with a mounting groove, the inside of the mounting groove is equipped with a roller 33 through a bearing, and the side of the blocking plate 31 is fixedly installed with An adjusting plate 34, and the side of the adjusting plate 34 is screwed with fastening bolts.

[0039] When this embodiment is in use, the sealing ring mechanism 3 can be pushed to move outside the feed pipe 9, and then the gap between the device and the furnace mouth of the incinerator can be blocked, so as to a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap