High-reliability environment-adaptability magneto-electric rotating speed sensor for engine and preparation method

An environmental adaptability, rotational speed sensor technology, applied to devices, instruments, speed/acceleration/shock measurement using electrical/magnetic methods, etc. Problems such as poor interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

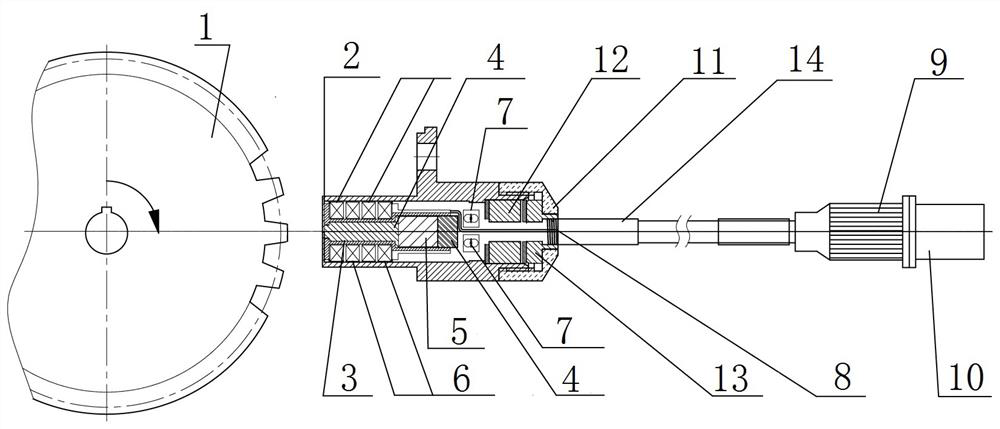

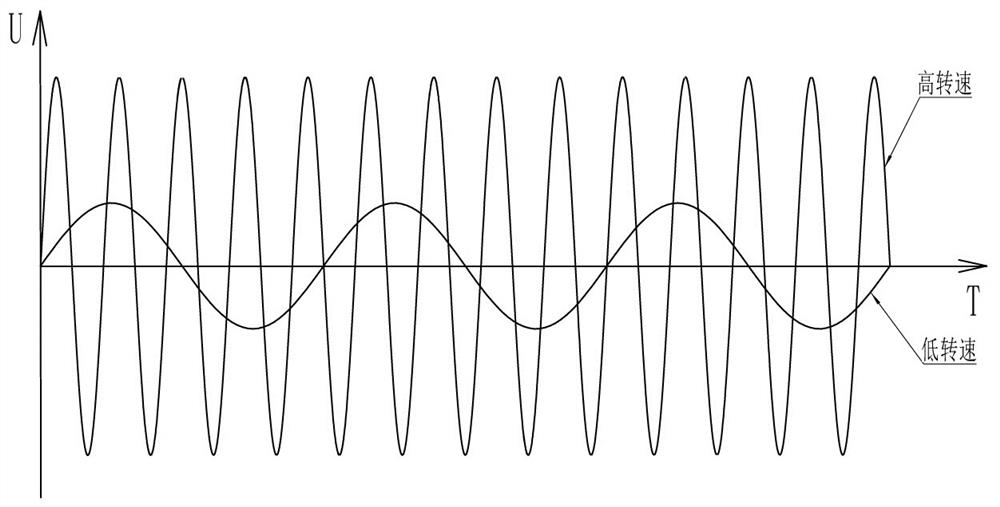

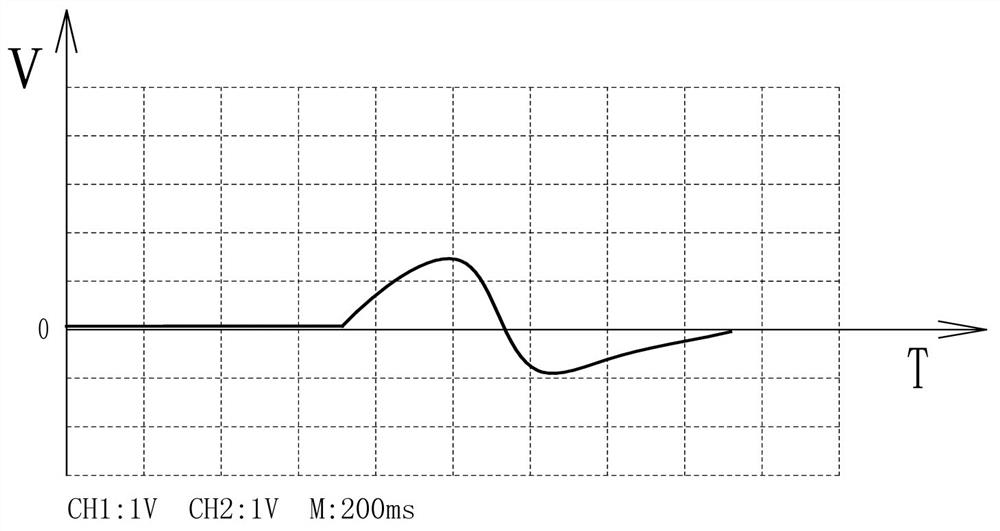

[0027] Such as Figure 1-3 Shown is a high-reliability environment-adaptable magnetoelectric speed sensor for an engine, including a test gear 1 and a sensor body that are connected to the engine to be tested and rotate synchronously; the sensor body includes a housing 2, inside the housing The front end is provided with a skeleton 3, an iron core 4 is arranged inside the skeleton, a magnetic steel 5 is arranged at the rear end of the iron core, and two sets of induction coils 6 are wound in a parallel synchronous manner on the outside of the skeleton; The internal rear end is between the induction coil and the signal output line, and there are two sets of toroidal transformers 7; the primary lead-out lines of the toroidal transformer are connected to the lead-out lines of the two sets of induction coils, and the secondary lead-out lines are connected to the speed signal output lines 8 connected; the output line of the rotational speed signal extends from the rear end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com