Viewing angle adjusting film structure, manufacturing method thereof and display device

A production method and a technology for adjusting the film, which are applied in the fields of nonlinear optics, instruments, optics, etc., can solve the problems of display panel display quality deterioration, display brightness and front viewing angle contrast reduction, etc., and achieve the goal of solving the problem of display brightness and front viewing angle contrast reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The application will be described in further detail below in conjunction with the accompanying drawings and embodiments. In particular, the following examples are only used to illustrate the present application, but not to limit the scope of the present application. Likewise, the following embodiments are only some of the embodiments of the present application but not all of them, and all other embodiments obtained by those skilled in the art without creative efforts fall within the protection scope of the present application.

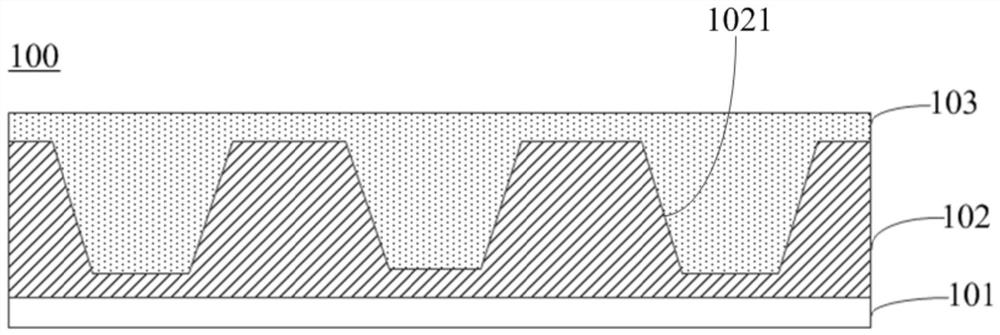

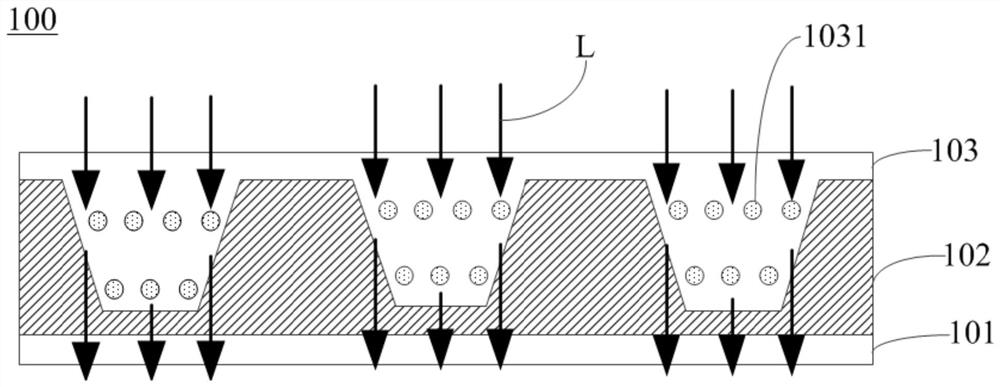

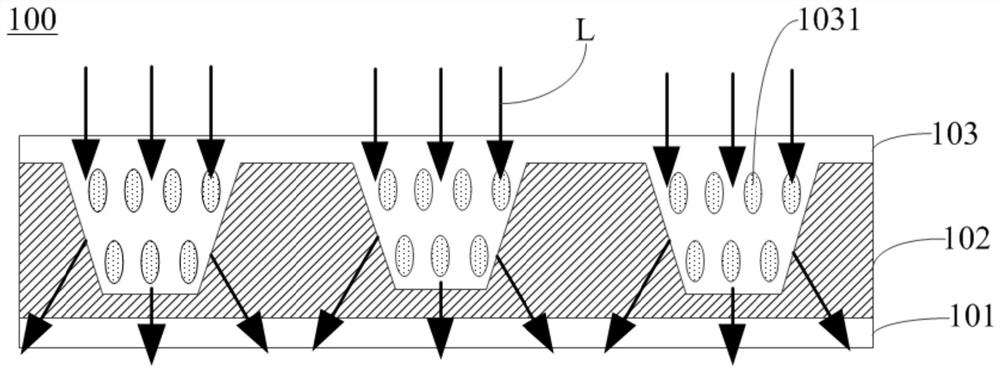

[0027] see Figure 1 to Figure 3 , figure 1 It is a schematic structural view of the viewing angle adjustment film structure provided in the embodiment of the present application, figure 2 It is a schematic diagram of the effect of adjusting the viewing angle of light by the viewing angle adjustment film structure provided in the embodiment of the present application, image 3 It is a schematic diagram of another effect of adjusting the view...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap