T-shaped vacuum induction smelting and casting furnace

A vacuum induction smelting and vacuum smelting technology, which is applied in ingot workshops, casting workshops, casting equipment, etc., can solve problems such as low casting efficiency, broken holes in the furnace, and products that do not meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

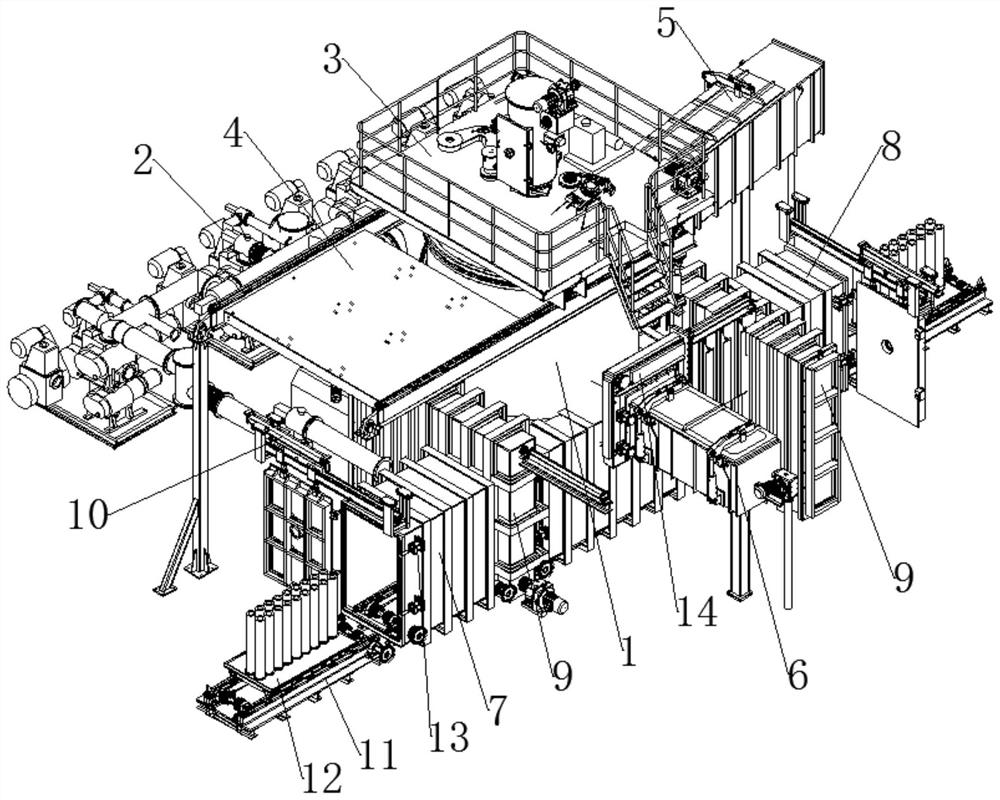

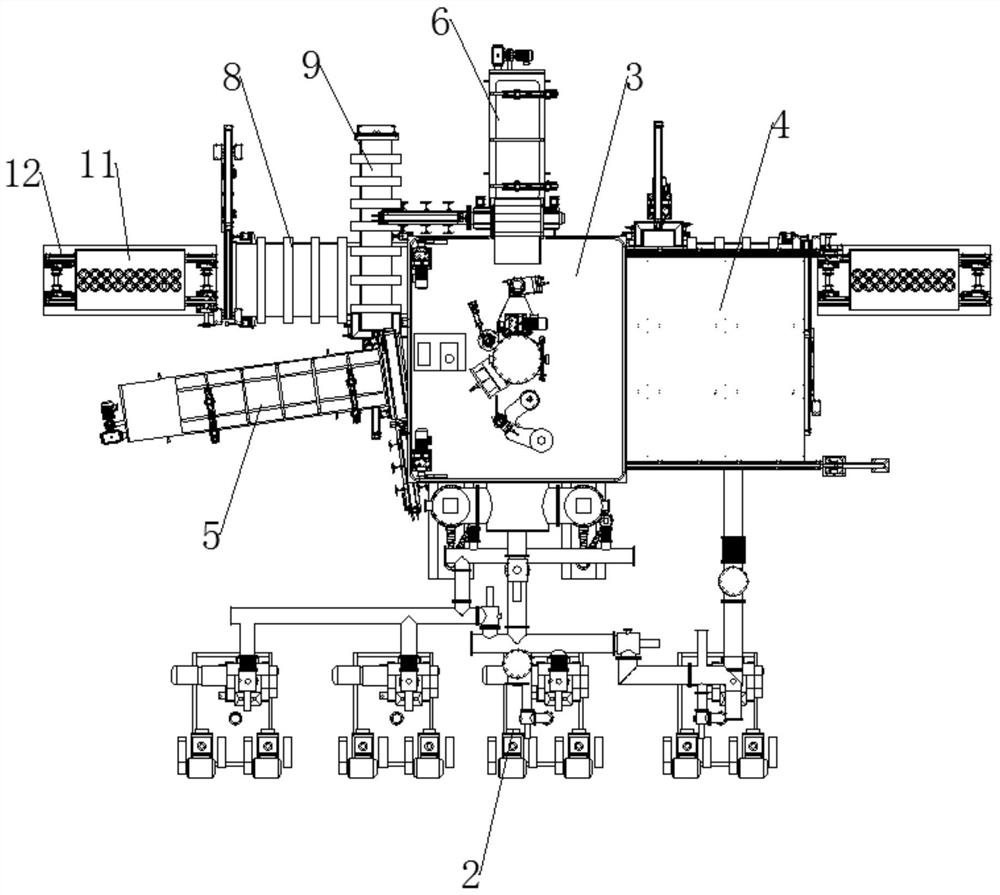

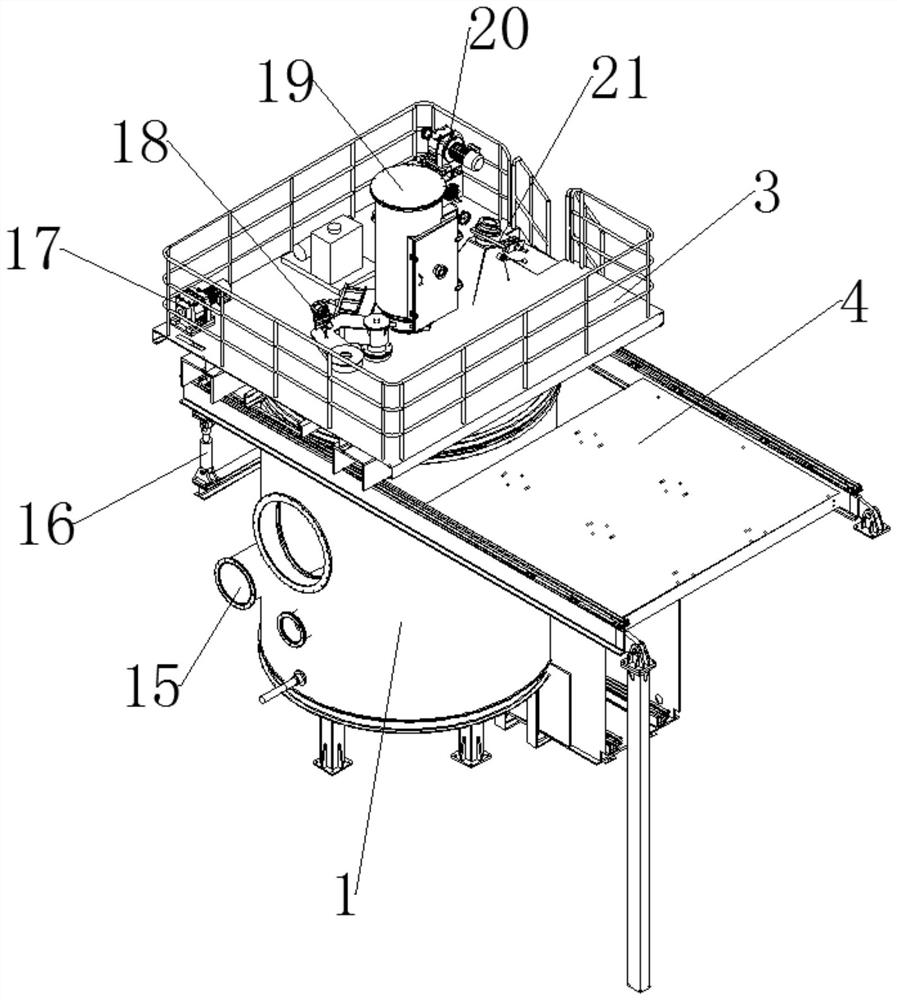

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, the T-type vacuum induction melting casting furnace mainly includes the following structures: a vacuum melting chamber 1, in which metal melting and casting are carried out; a melting furnace 23, installed in the vacuum melting chamber 1 for melting metal; There are four vacuum valves 2, which are respectively arranged outside the vacuum smelting chamber 1, connected to the vacuum smelting chamber 1 through pipes, and different vacuum levels can be achieved by switching the inside of the vacuum smelting chamber 1 in different forms; moving the furnace cover 3 , installed on the top of the vacuum melting chamber 1, the inside of the vacuum melting furnace 23 can be overhauled and parts replaced by opening the movable furnace cover 3; side, which plays the role of buffering; the transmission device 11 runs through the entire vacuum melting chamber 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com