Composite material storage battery trolley and manufacturing method thereof

A technology of composite materials and manufacturing methods, applied in the field of rail transit, can solve the problems of increasing the load of the hanging equipment at the bottom of the carriage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

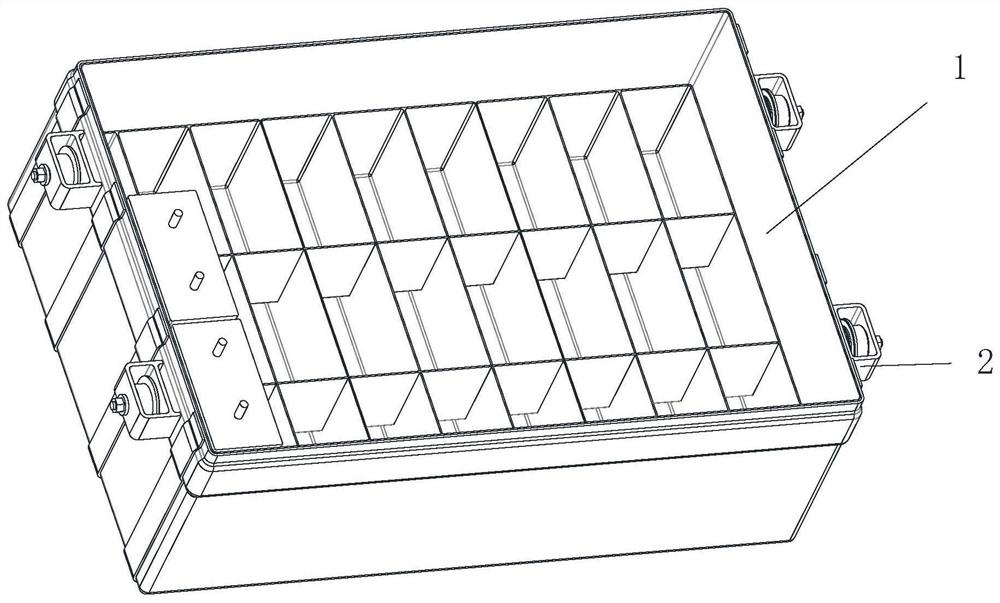

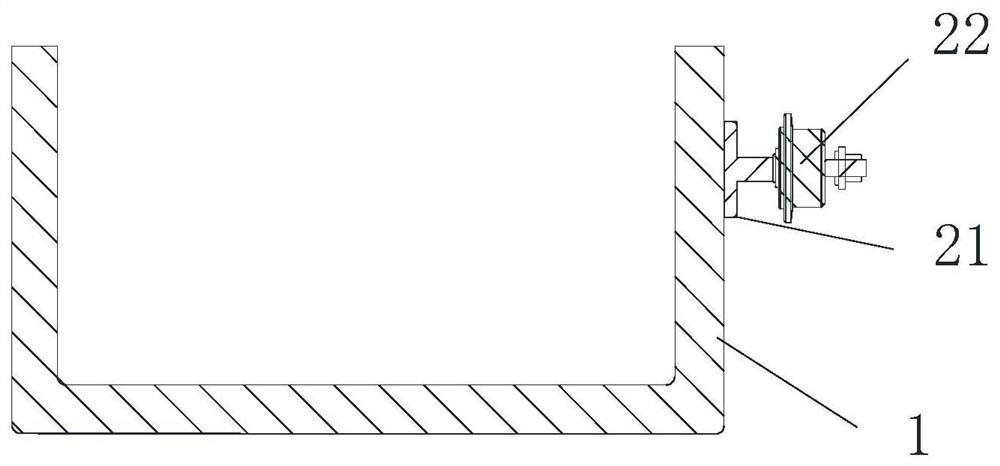

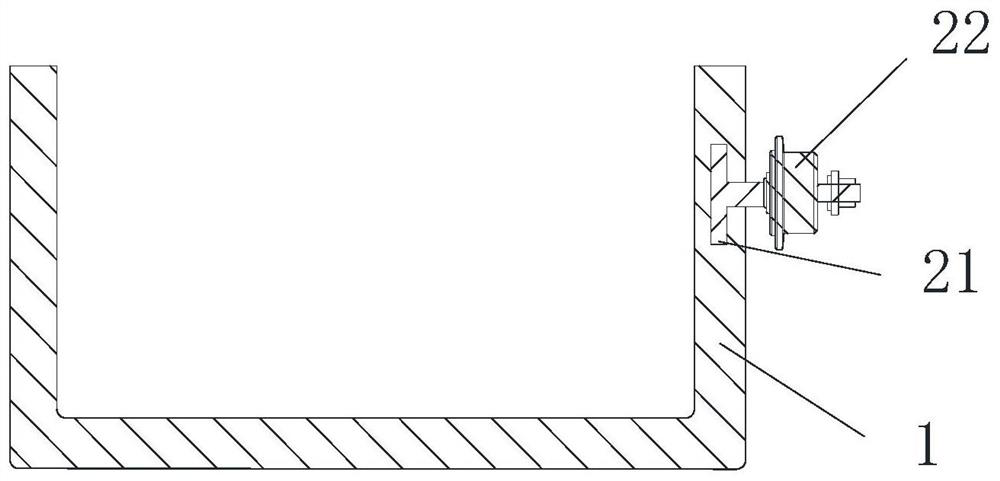

[0035] Such as figure 1 , Figure 2a , Figure 2b Figure 2c The shown composite battery trolley includes a tray 1 and a pulley assembly 2; the tray 1 includes an upwardly opening accommodating chamber 11 for placing the battery; the pulley assembly 2 includes a pulley support structure 21 and a wheel body that is rotatably connected to the pulley support structure 21 22. The pulley support structure 21 is partly or entirely located outside the tray 1, and is used to provide an installation position for the wheel body 22. The pulley assembly 2 is rolled on the guide rail in the battery box; the tray 1 and the pulley support structure 21 are composite material struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com