A kind of encapsulation machine and encapsulation method

A glue wrapping machine and glue wrapping technology, which is applied in the field of glue wrapping machines, can solve the problems that the heat sink cannot be clamped, the heat sink is easy to loosen, and the glue wrap is not in place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The following is a further detailed description through specific embodiments:

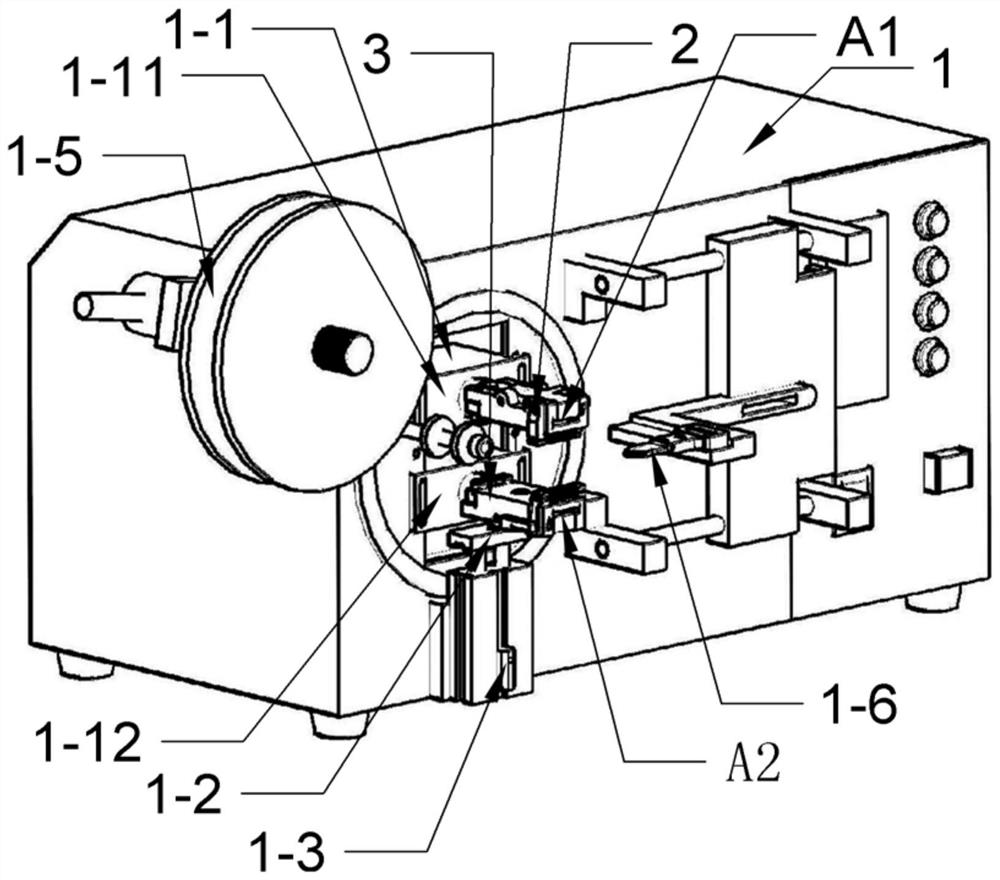

[0066] In order to realize the clamping of the encapsulated parts by the double-shaft encapsulation machine, take the encapsulated part as an example with a heat sink with a metal body on the surface, such as Figure 1-5 As shown, the present embodiment provides an encapsulation machine, including:

[0067] The main body 1 of the laminating machine, and the first clamp 2 and the second clamp 3 fixedly installed on the main body 1 of the laminating machine. The first clamp 2 clamps the first heat sink A1, and the second clamp 3 clamps the first heat sink Two heat sink A2.

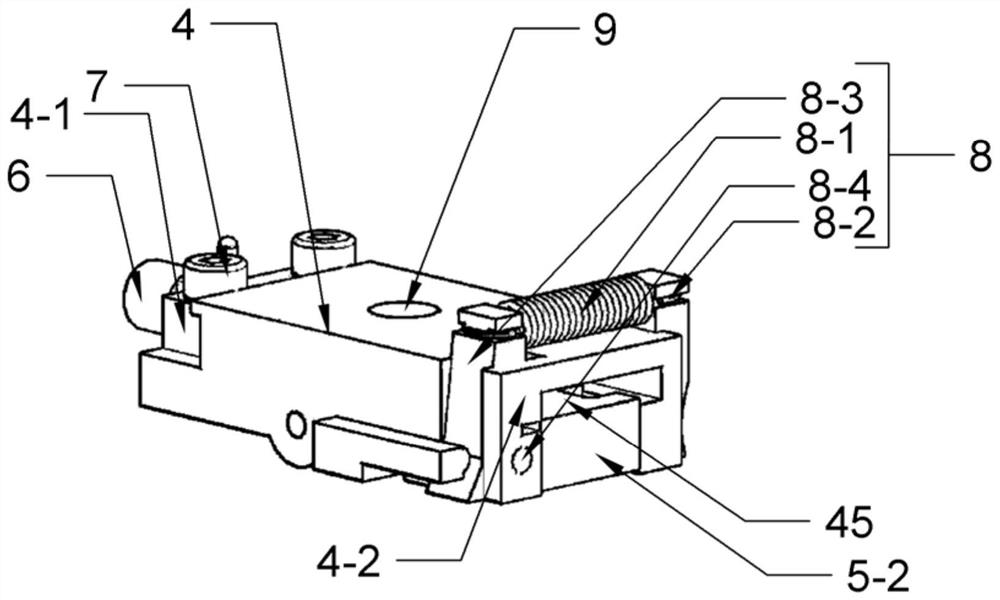

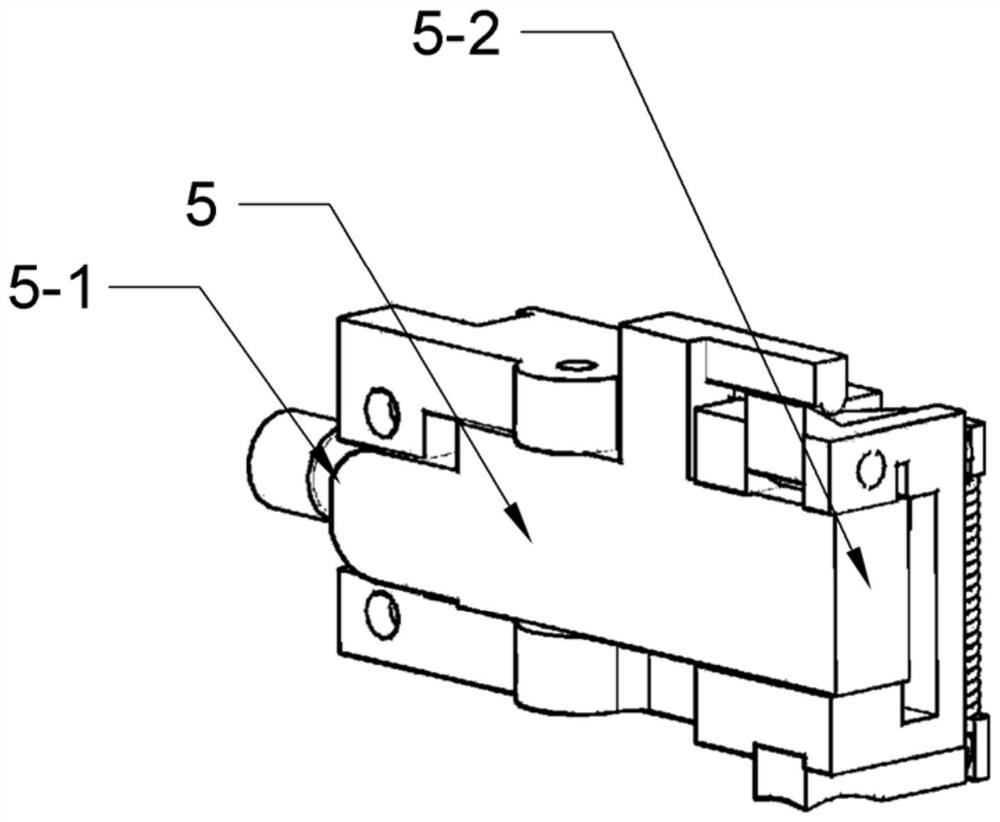

[0068] (1) The first jig 2 and the second jig 3

[0069] In this embodiment, the structures of the first clamp 2 and the second clamp 3 are the same, and the specific structure of each clamp will be described below by taking the first clamp 2 as a representative.

[0070] The first fixture 2 includes:

[0071] 1) the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com