Fixing frame for electromechanical equipment and installation method thereof

An installation method and technology of electromechanical equipment, applied in the direction of mechanical equipment, machine platform/bracket, supporting machine, etc., can solve the problems of large spring loss and poor shock absorption effect, and achieve vibration reduction, good cushioning effect, and good shock absorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

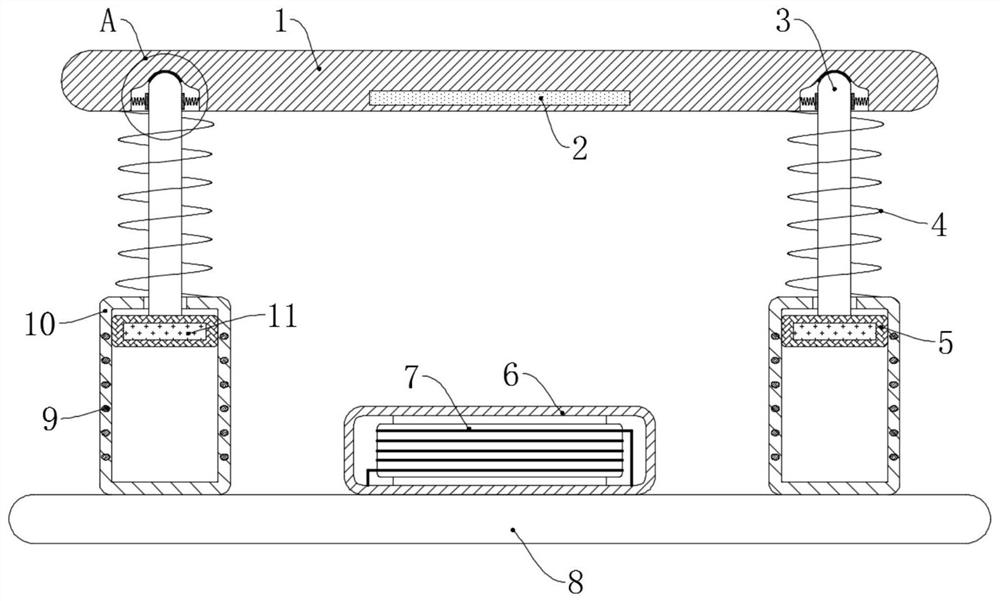

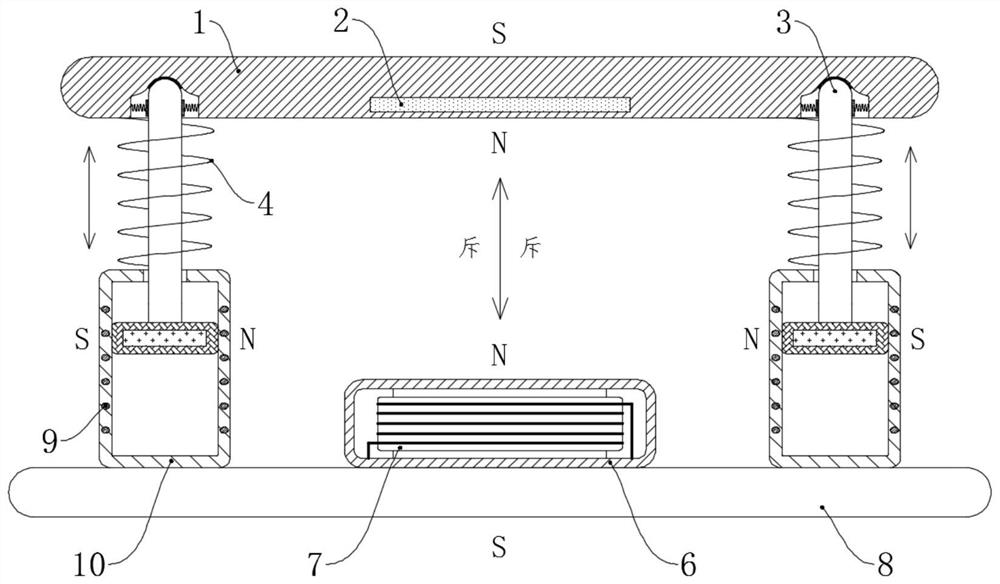

[0032] refer to Figure 1-3 , a method for installing a fixing frame for electromechanical equipment, the specific steps are as follows:

[0033] S1: Fix the protective box 6 and the two vertical cylinders 10 on the bottom plate 8 by bolts;

[0034] S2: Fix the magnetic block 11 to the bottom end of the support rod 3 and put the anti-wear sleeve 5 on the magnetic block 11, and then put the two magnetic blocks 11 into the two vertical tubes 10 respectively;

[0035] S3: welding one end of the first spring 4 to the upper surface of the vertical cylinder 10, and welding the other end to the upper side wall of the support rod 3;

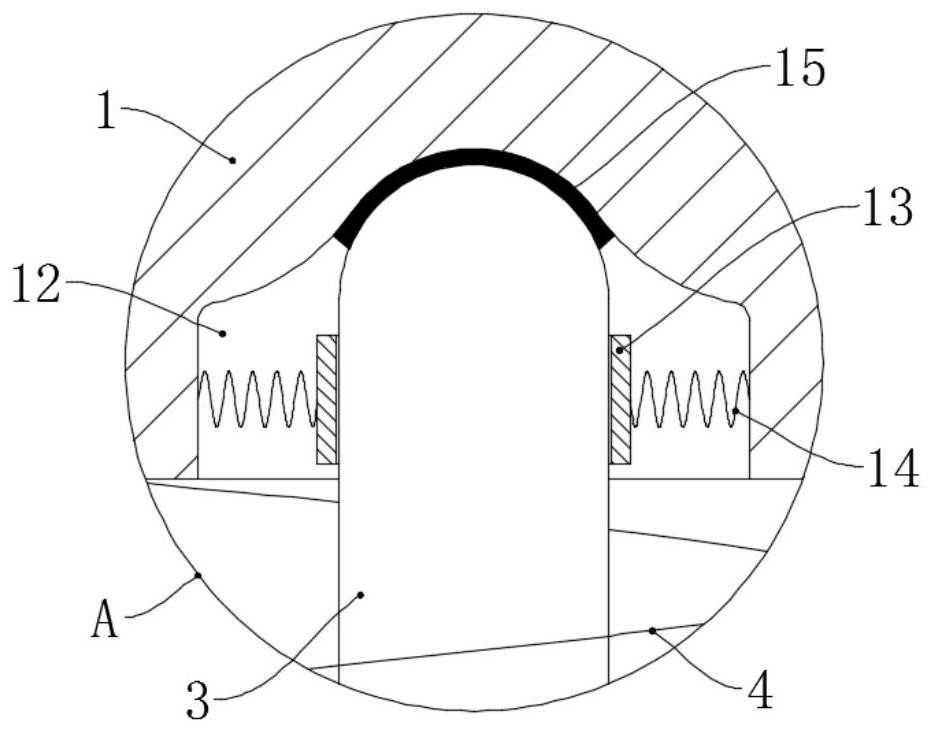

[0036] S4: welding a plurality of second springs 14 with arc-shaped plates 13 symmetrically in the two assembly grooves 12 and fixing the buffer member 2 under the stage 1;

[0037] S5: Make the two support rods 3 stably support the stage 1 through the assembly groove 12, and the arc-shaped plate 13 in the same assembly groove 12 is offset against the ...

Embodiment 2

[0048] refer to Figure 4-6 The difference between this embodiment and Embodiment 1 is that: a chute 16 is provided in the stage 1, and the buffer member 2 is movably placed in the chute 16, and the buffer member 2 includes two permanent magnet plates with the same polarity direction. The side wall of the chute 16 is bonded with a circle of buffer sheet 17 in the circumferential direction, and the middle part of the chute 16 divides the internal space of the chute 16 into two parts by the buffer sheet 17. Two permanent magnet plates are respectively located on the two sides of the buffer sheet 17 On the other hand, the buffer sheet 17 can avoid the damage or demagnetization of the permanent magnet plate caused by the rigid collision between the buffer member 2 and the chute 16 .

[0049] During specific work, when the electromechanical equipment is subjected to vibration in the horizontal direction, the second spring 14 and the rubber gasket 15 still have the effect of weakeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com