Airplane surface bolt tightening detection method

A technology of aircraft surface and detection method, applied in the direction of computer parts, instruments, character and pattern recognition, etc., which can solve the problems of insufficient temporary information supplement ability, high operational risk, and reduced data traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

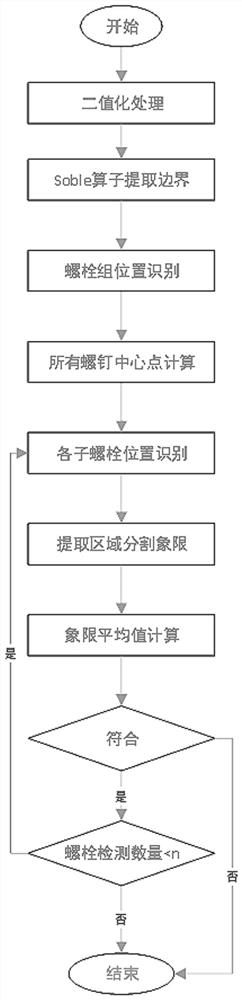

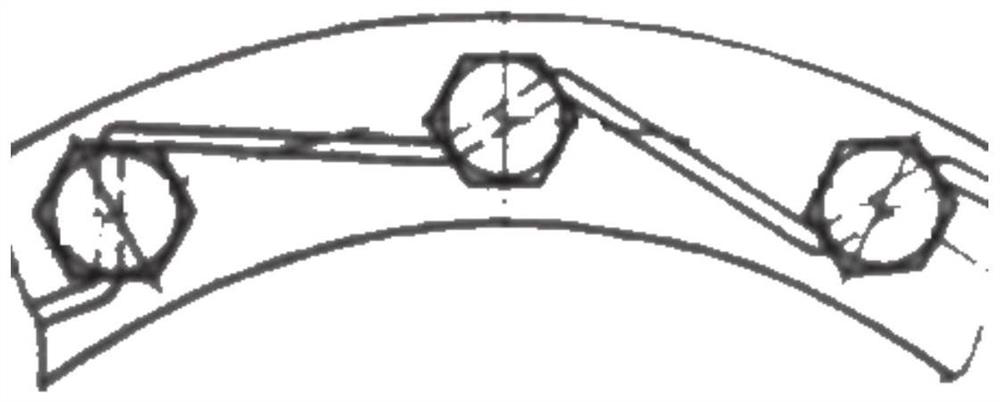

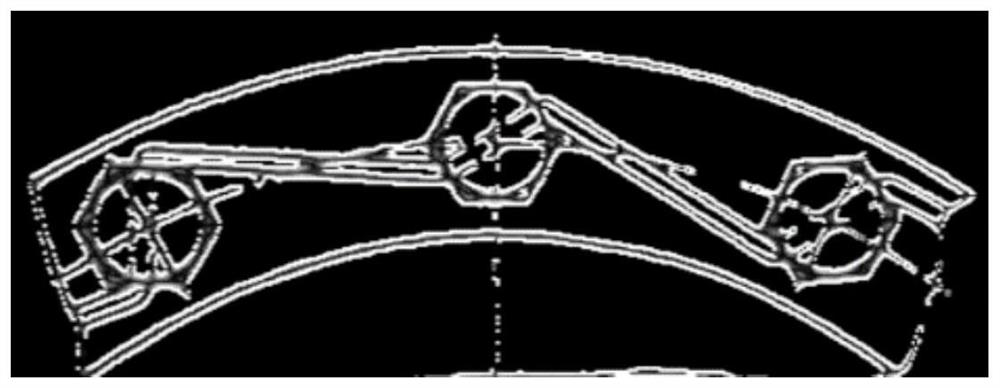

[0060] Aircraft surface bolt tightening detection method, such as Figure 1-8 As shown, the system establishes local feature samples based on the bolt group as a whole. First, the circular contours of each bolt in the bolt group are extracted, and the feature samples are constructed based on the relative positional relationship between the center points of the circular contours. When the system is running, the system is Match the features of this sample within the captured image range. After the matching is successful, intercept its local area and save it for bolt tightening state detection. The specific steps include the following steps:

[0061] S1: System initiali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com