Ceramic base of high-voltage direct-current contactor and assembling method thereof

A ceramic base, high-voltage direct current technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of not meeting the design requirements, reducing the reliability and life performance of contactors, and reducing the wear resistance of contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention provides a ceramic base of a high-voltage DC contactor, the base is used for the installation of the contactor body, the connection between the contactor body and the external load is realized through the terminal on the base, and the power loaded on the external load is controlled on and off.

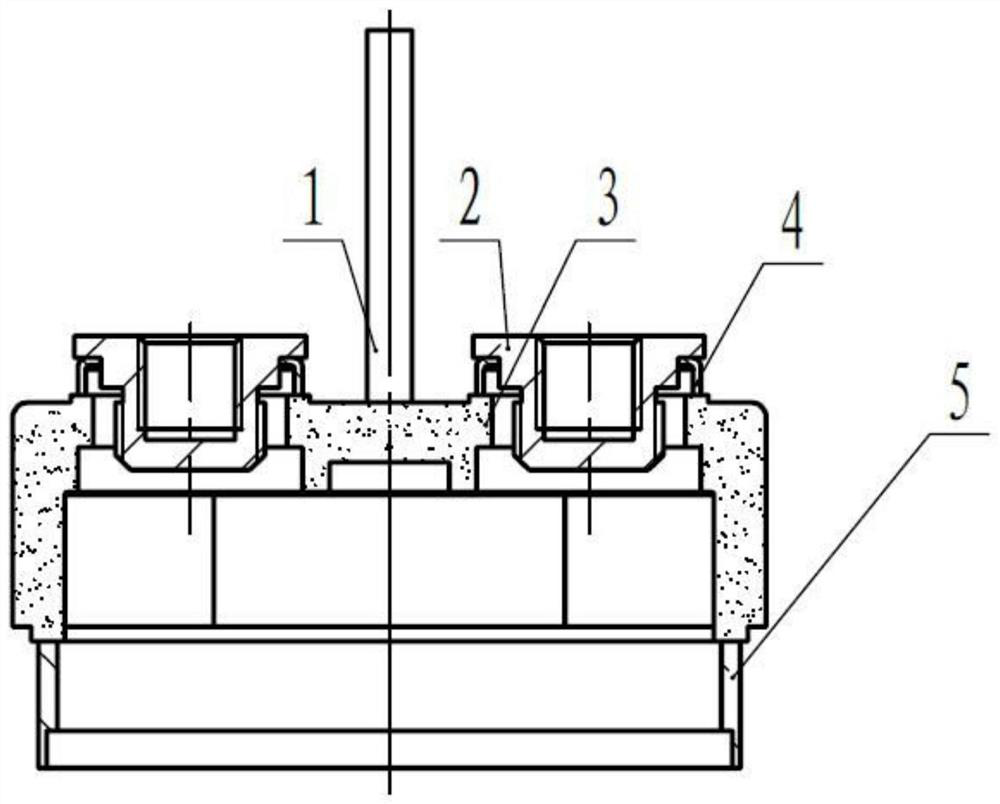

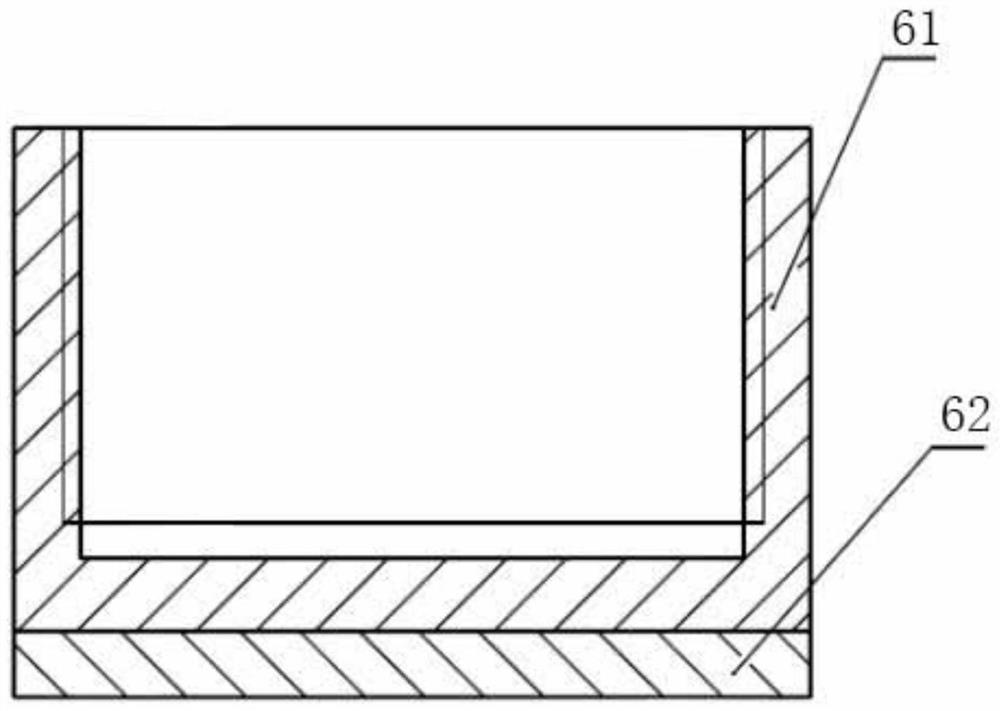

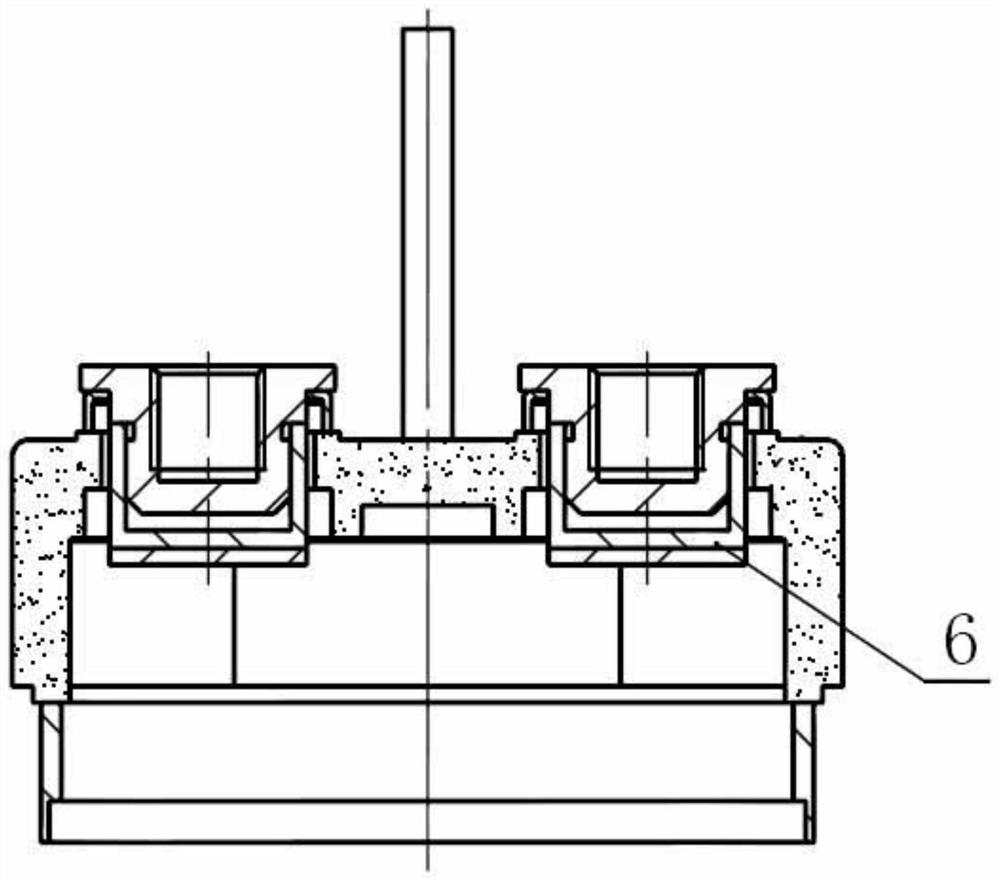

[0015] Such as figure 1 and image 3 As shown, the ceramic base is a cavity structure, including a non-sealed ceramic base cavity for installing the contactor body and a contact 6 screwed into the cavity of the ceramic base. The contact 6 is used for contacting The contacts on the body of the device form a circuit / break circuit to control the on-off of the power loaded on the load. The contactor body described here refers to the control circuit part of the contactor.

[0016] Among them, the ceramic base cavity includes a base body 3, an air extraction pipe 1, a terminal post 2 and a first sealing ring 4; one end of the air extraction pipe 1 is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com