Isolated fireproof power distribution cabinet

A power distribution cabinet and cabinet technology, which is applied in the substation/distribution device shell, electrical components, fire rescue and other directions, can solve the problems of paralysis of the whole set of equipment, direct economic losses, and no automatic fire extinguishing device in the power distribution cabinet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

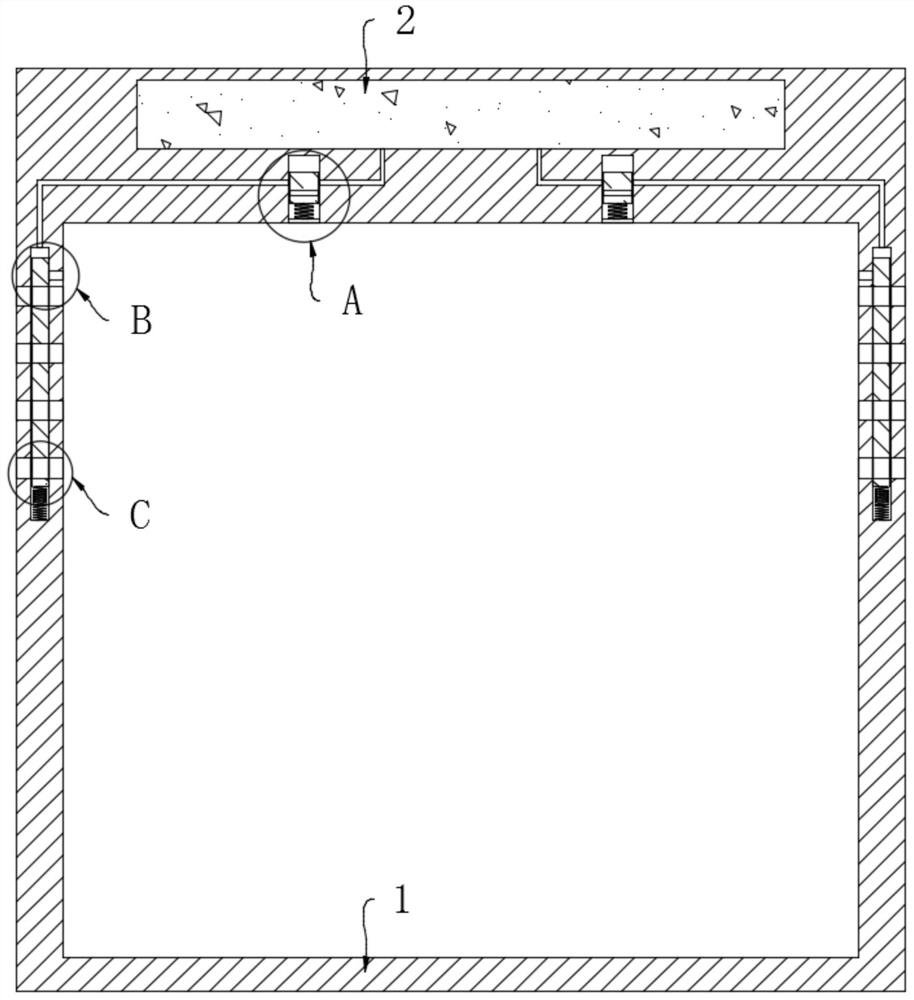

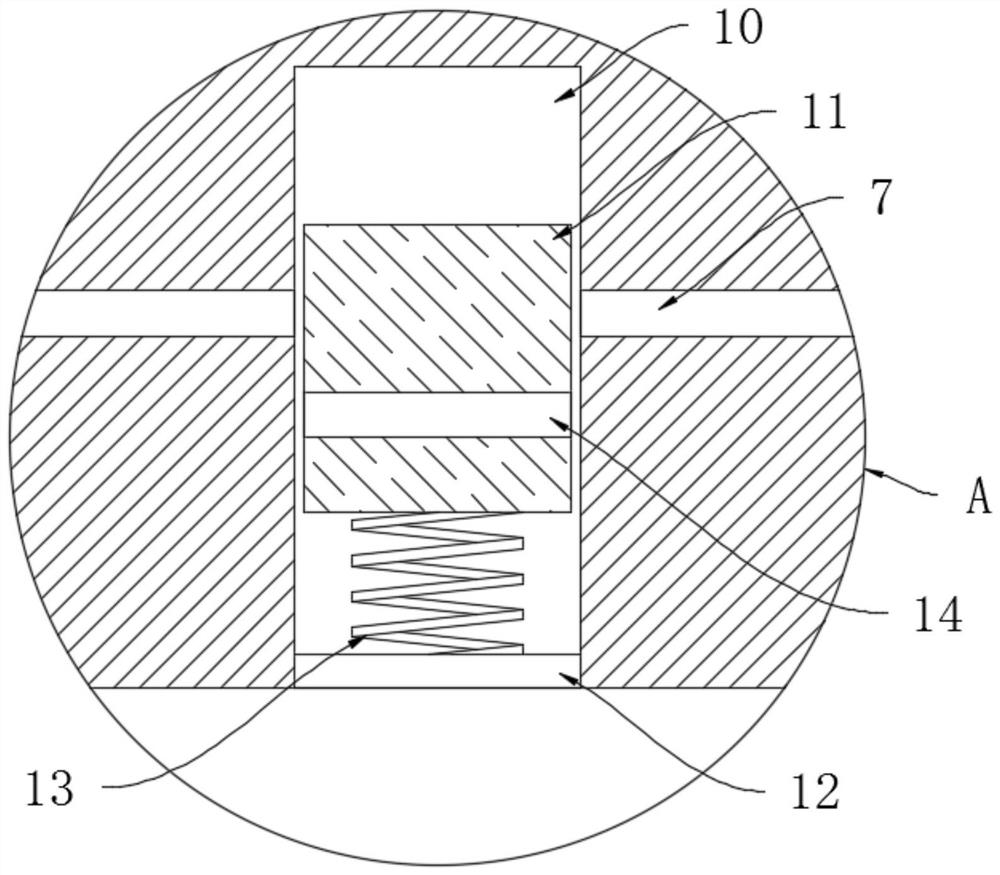

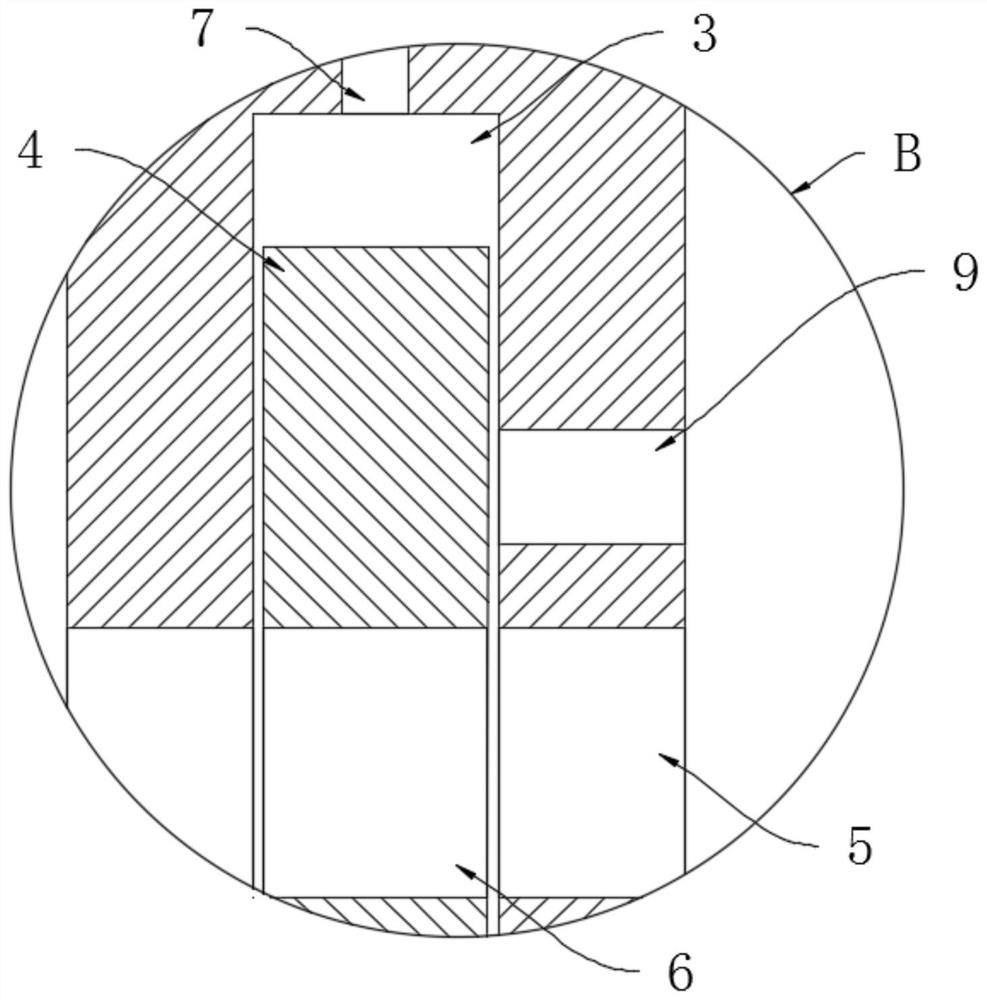

[0021] refer to Figure 1-4 , an isolated fireproof power distribution cabinet, including a cabinet body 1 for installing electrical devices, a liquid storage tank 2 for filling a fire extinguishing agent is opened at the upper end of the cabinet body 1, and the fire extinguishing agent is high-pressure carbon dioxide gas, and the side wall of the cabinet body 1 The upper end is symmetrically provided with chute 3, and each chute 3 is elastically connected with a slider 4 through a return spring 8, and each slider 4 is sealed and slidably connected with the corresponding chute 3, and the groove wall of each chute 3 There are vents 5 that connect the chute 3 with the outside world and the interior of the cabinet body 1 symmetrically on the top. Each slider 4 is provided with a plurality of through holes 6 that cooperate with the vents 5. The grooves of each chute 3 The upper end of the wall is provided with an air intake pipe 9 connecting the chute 3 with the interior of the ca...

Embodiment 2

[0027] refer to Figure 5-6 The difference between this embodiment and Embodiment 1 is that: the lower end of the side wall of the cabinet body 1 is symmetrically provided with a second control groove 15, and the inner bottom wall of each second control groove 15 is elastically connected with a piston through a second memory spring 16. plate 17, and the side walls of each piston plate 17 are sealed and slidably connected with the groove wall of the corresponding second control groove 15, and the second memory spring 16 can be made of a thermally deformable metal material with a transformation temperature of about 200 degrees Celsius. A connecting pipe 18 is connected between the top groove wall of the second control groove 15 and the corresponding drive zone, and the sealed space formed by the upper end surface of the piston plate 17 and the second control groove 15 is a control zone, and each control zone is connected to the corresponding drive zone. The connecting pipes 18 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com