Novel girder-free photovoltaic module mounting bracket

A technology for photovoltaic modules and mounting brackets, which is applied to the support structure of photovoltaic modules, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of complex structure, multiple labor, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

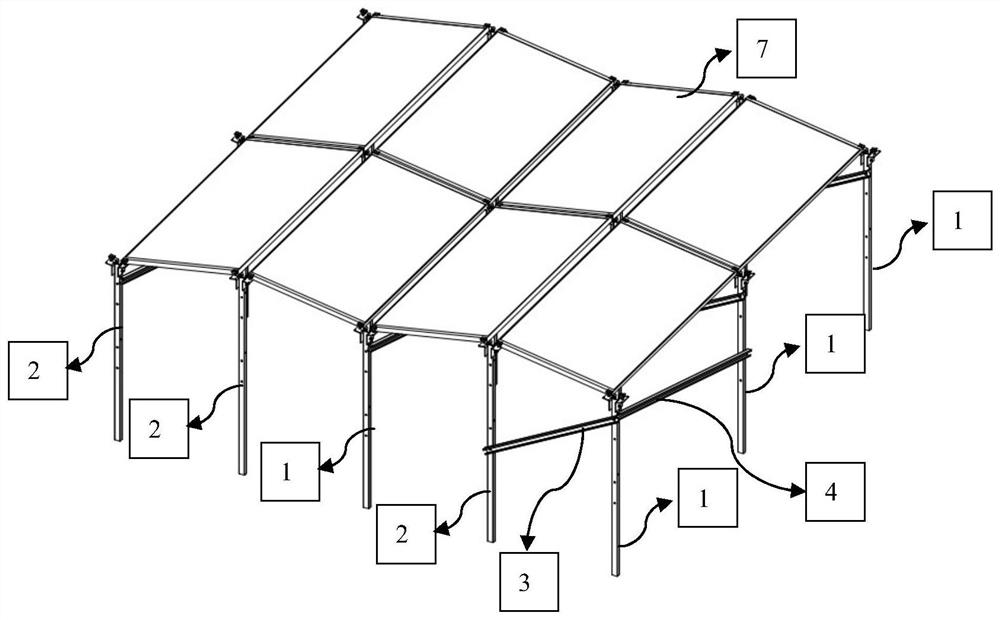

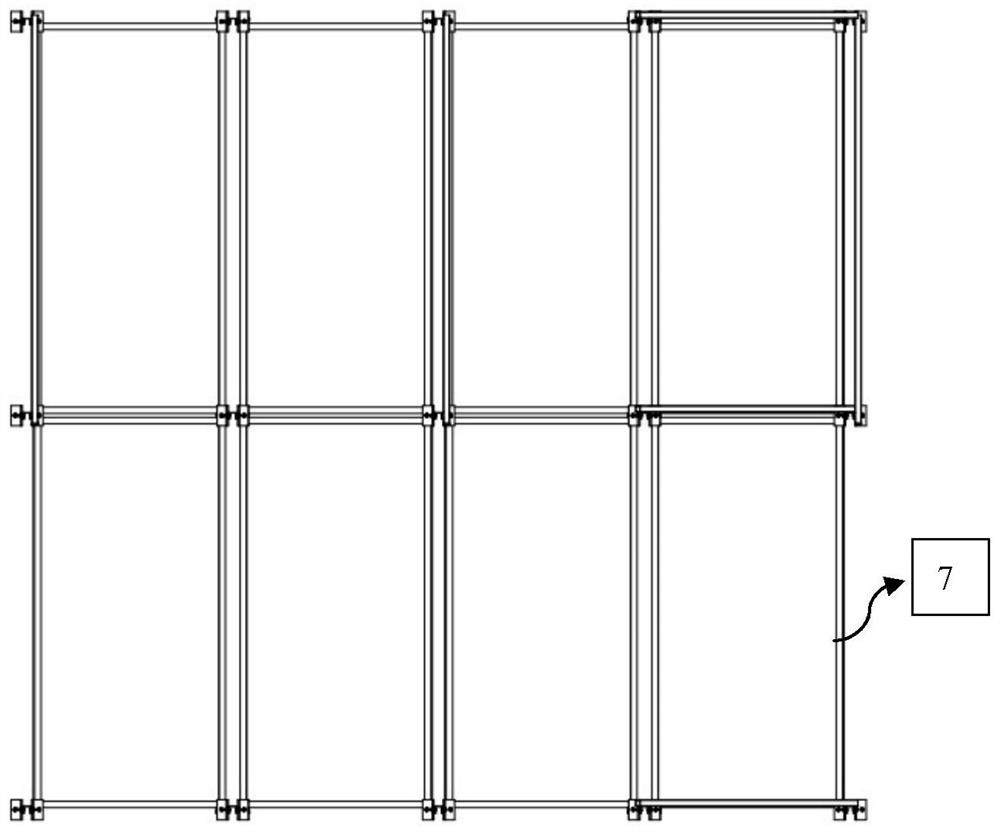

[0038] The present invention is a new main-beam-less photovoltaic module mounting bracket. The photovoltaic bracket provided by this scheme has a simple structure, a small number of parts, and a simple production process; the main parts of this structure are only three kinds-upright columns, diagonal braces and nodes The plate, column and diagonal brace are of the same cross-section, and the overall processing is simple; specific, such as figure 1 As shown, the photovoltaic support includes:

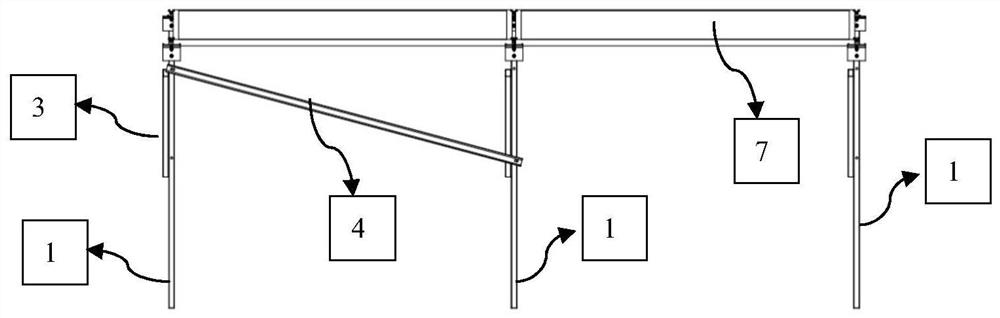

[0039] A column, the column is installed vertically, and is used to provide the supporting force in the vertical direction for the photovoltaic module;

[0040] Diagonal bracing, the diagonal bracing is installed at an angle to the horizontal direction, and its two ends are fixed on the column;

[0041] A gusset plate, the gusset plate is installed on the column, mounting holes are provided on different heights of the column for installing the gusset plate, through the mounting hole, th...

Embodiment 2

[0056] Based on a new main-beam-free photovoltaic module mounting bracket provided in Example 1, this embodiment provides an assembly method for the photovoltaic bracket. After the first column and the second column are driven into the ground by a piling machine, diagonal braces are installed to control the overall After stabilization, install the first and second gusset plates (No. 5 and 6) and adjust to the angle and height required by the design, then install the components, and fix the components on the adjustment plate with pressing blocks.

[0057] The assembly process of the bracket is convenient, which solves the problem of a large number of bracket parts and inconvenient installation. The number of parts is small, and each is relatively independent, and the production, transportation and installation are easy to operate, which can greatly improve the photovoltaic bracket system. production efficiency and installation efficiency. The components used in the invention ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com