Eccentric shaft structure of medical reciprocating saw handpiece

A technology of eccentric shaft and reciprocating saw, applied in the field of eccentric shaft structure, can solve the problems of inconvenient operation of medical reciprocating saw handpiece, low height, easy wear of eccentric shaft and sliding sleeve, heating speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

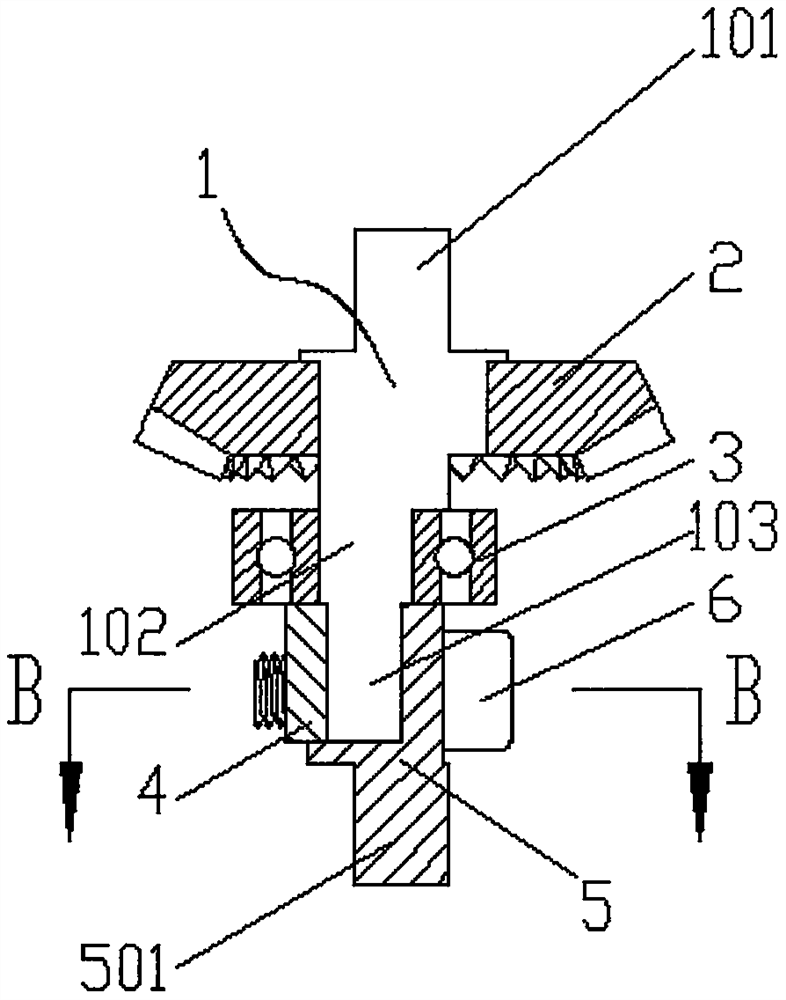

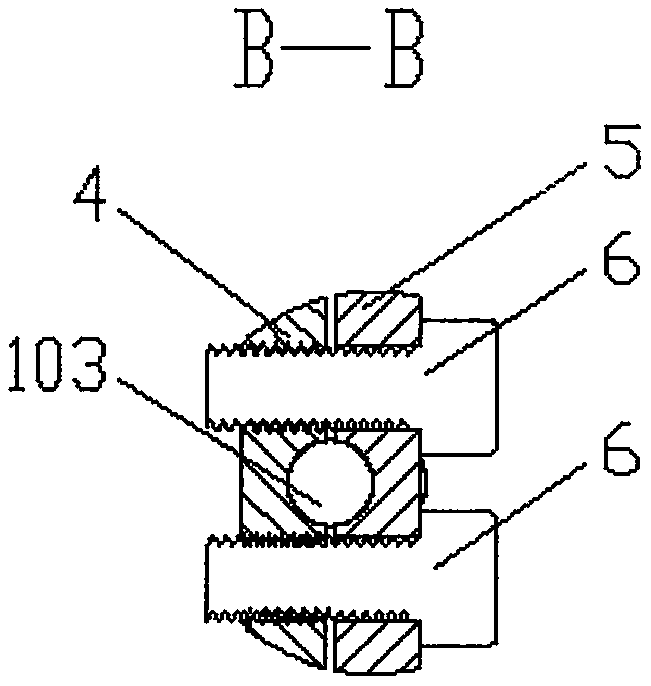

[0012] In order to describe the technical contents and structural features of the present invention in detail, further detailed descriptions are given below in conjunction with the implementations and drawings.

[0013] An eccentric shaft structure of a medical reciprocating saw mobile phone, including the eccentric shaft main body (1), bevel gear (2), bearing (3), left pressing block (4), right pressing block (5) and locking screw (6) , the eccentric shaft main body (1) and the bevel gear (2) are nested and fixed together, the bearing (3) is installed on the middle shaft (102) of the eccentric shaft main body (1), the The left pressing block (4) and the right pressing block (5) are respectively provided with grooves matching with the lower end shaft (103) of the eccentric shaft main body (1), and are tightened on the said locking screw (6) On the lower end shaft (103) of the eccentric shaft main body (1), the end of the right press block (5) is provided with a right press blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com