Sewage purification treatment device for factory discharge

A sewage purification and treatment device technology, which is applied in chemical/physical processes, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of low efficiency, inability to spread medicine evenly, and large demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

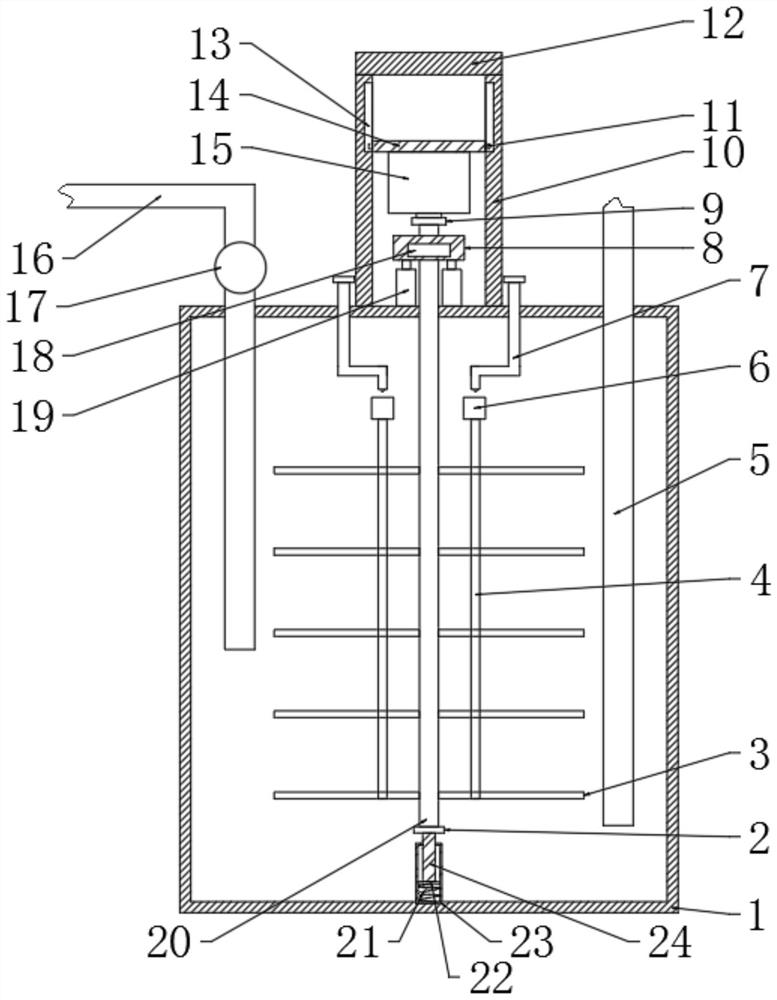

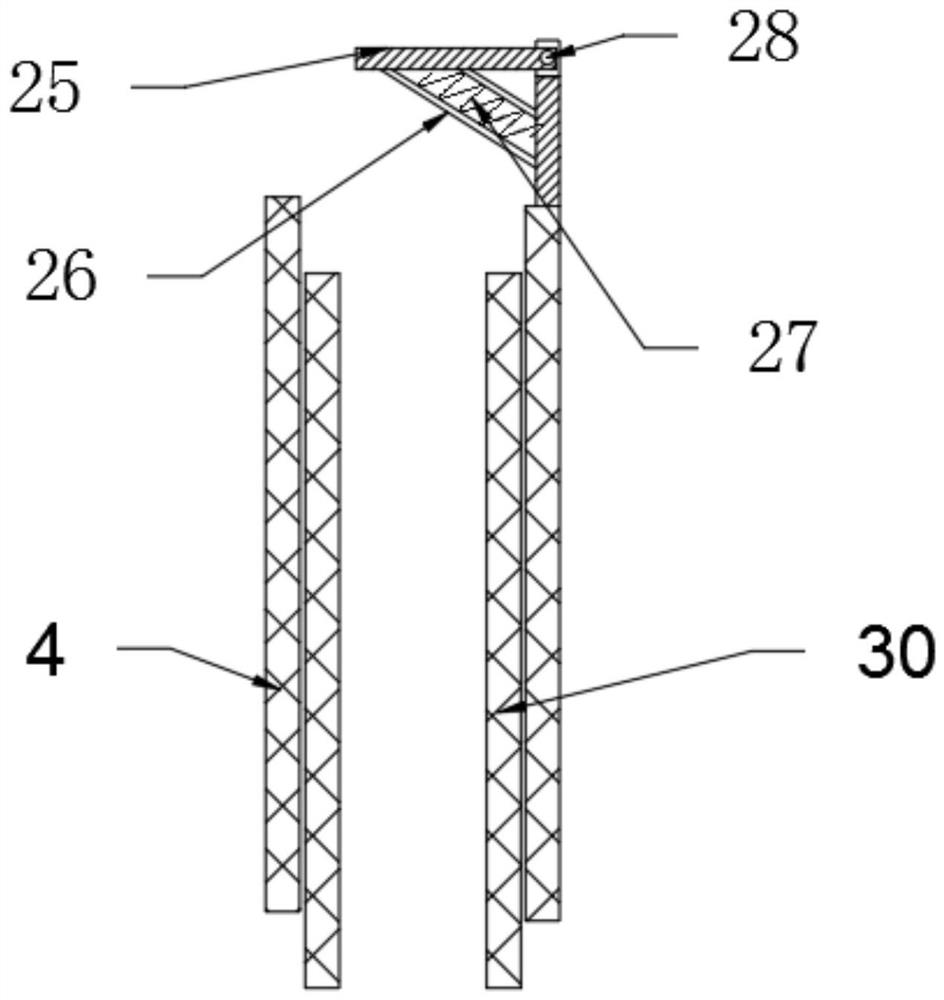

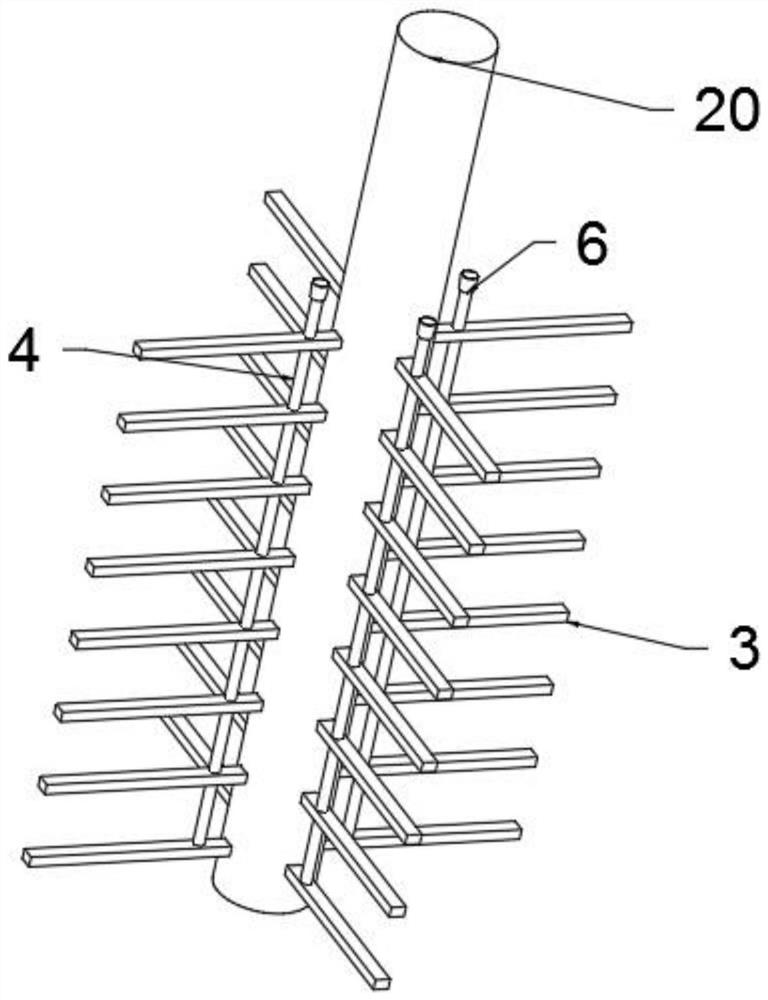

[0020] see Figure 1-4 , a sewage purification treatment device for factory discharge, comprising a box body 1, a water inlet structure and a sewage treatment structure, the side of the box body 1 is fixedly provided with a water inlet structure, and the side of the water inlet structure is provided with a sewage treatment structure , the sewage treatment structure includes a lifting mechanism, a power mechanism, a medicine entering pipeline 7, a receiving seat 6, a medicine spreading pipeline 4, fan blades 3, a rotating shaft 20, a medicine spreading internal pipeline 30 and a medicine spreading hole 29, and the box body 1 The top is fixed with a lifting structure, the middle of the lifting mechanism is rotatably connected to the rotating shaft 20, and the end of the rotating shaft 20 is rotatably connected to a power mechanism, and the rotating shaft 20 is fixedly provided with a number of uniformly arranged fan blades 3, and the fan blades 3 There is a spraying pipeline 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com