Advancement agency

A technology of a propulsion mechanism and a rotating mechanism, which is applied in the directions of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as supporting settings, and achieve the effect of reducing space and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

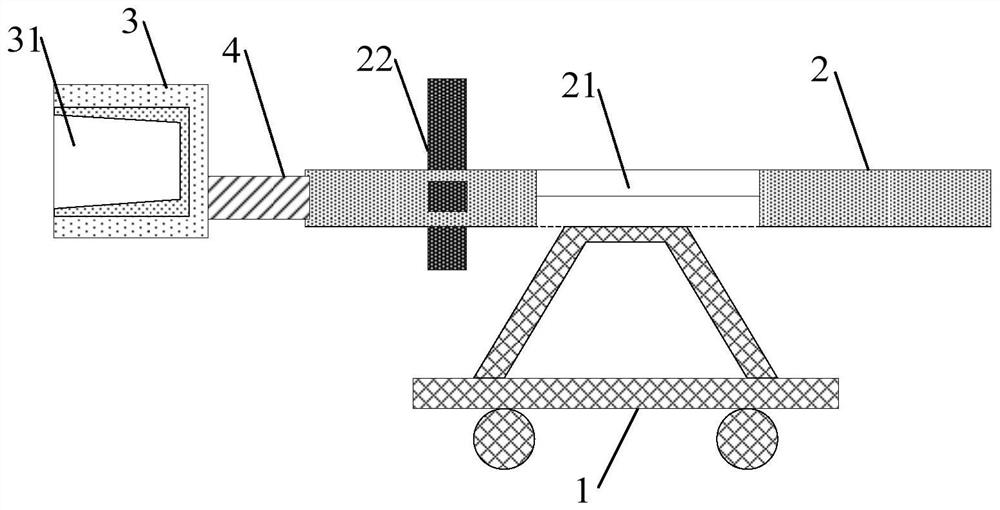

[0033] FIG. 1 illustrates a schematic structural diagram of a propulsion mechanism according to an embodiment of the present invention. As shown in Figure 1, the propulsion mechanism package

[0044] Further, each support rod 22 in the plurality of support rods 22 is provided with a roller at one end away from the push rod 2. This

[0046] Wherein, the soft material can be a sponge, a rubber pad, etc., which is not limited in the embodiment of the present invention. Cavity 31 can be

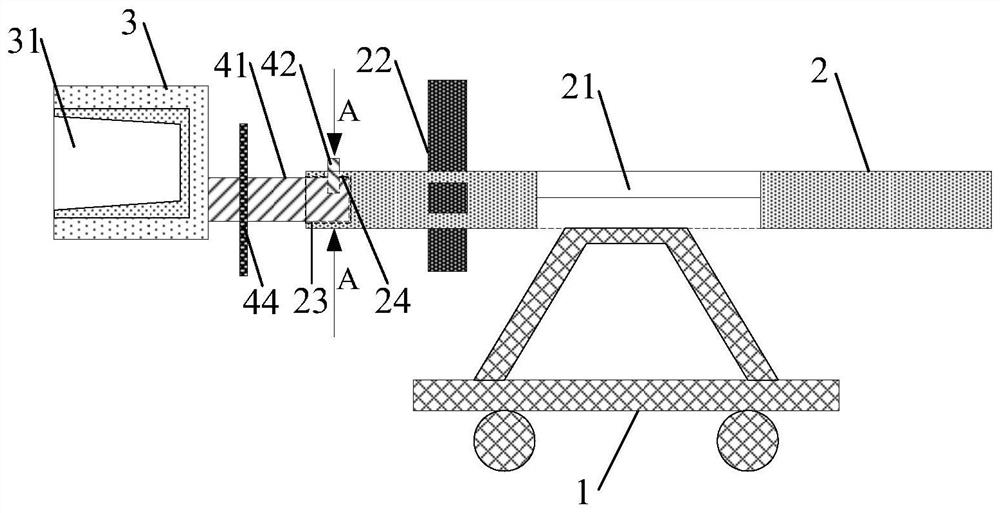

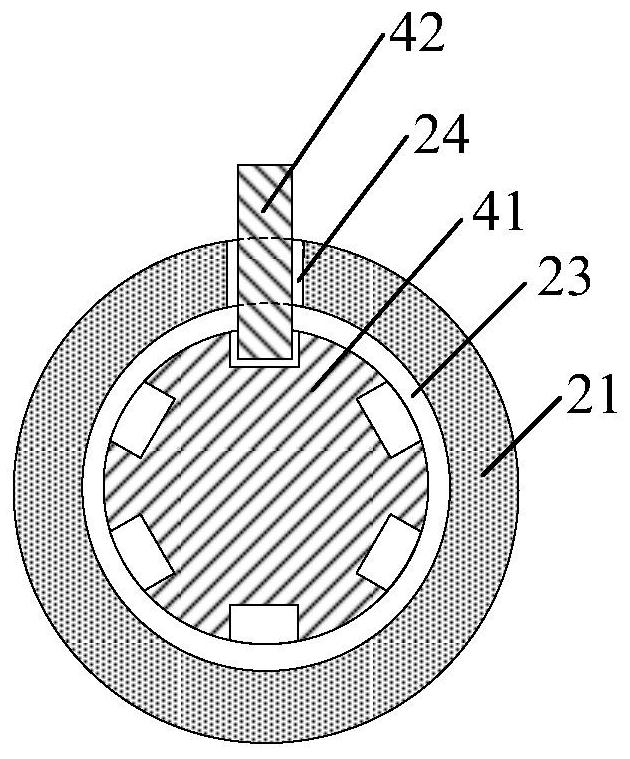

[0047] In the embodiment of the present application, as shown in FIG. 2 and FIG. 3, the rotating mechanism 4 may include a fixed rod 41 and a fixed latch 42,

[0049] Wherein, the cross section of the fixing rod 41 can be circular, of course, can also be a polygonal structure. The groove 23 can be

[0054] Wherein, the cross section of the fixed rod 41 can be circular, of course, can also be a polygonal structure. The groove 23 can be

[0058] Wherein, the actual structure of the fixing rod 41 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com