Self-circulation heat radiating type cutting machine

A cutting machine and headstock technology, applied in metal sawing equipment, sawing machine accessories, sawing machine devices, etc., can solve problems such as high temperature of the main shaft and bearings, expansion of the main shaft and bearings, and increased cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

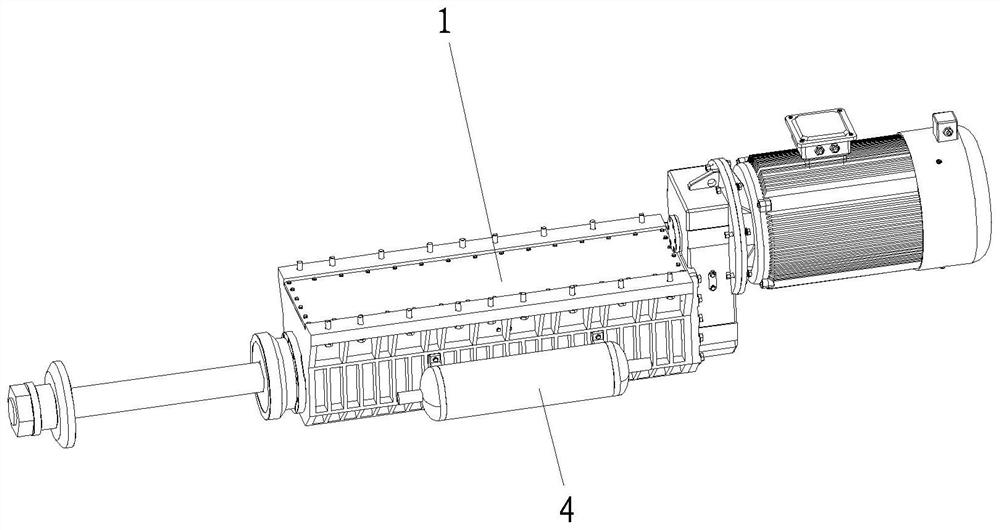

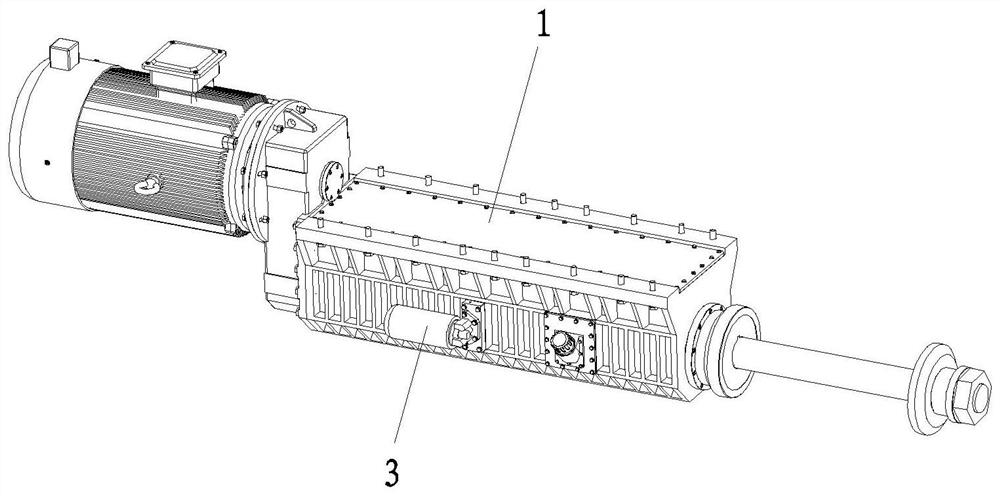

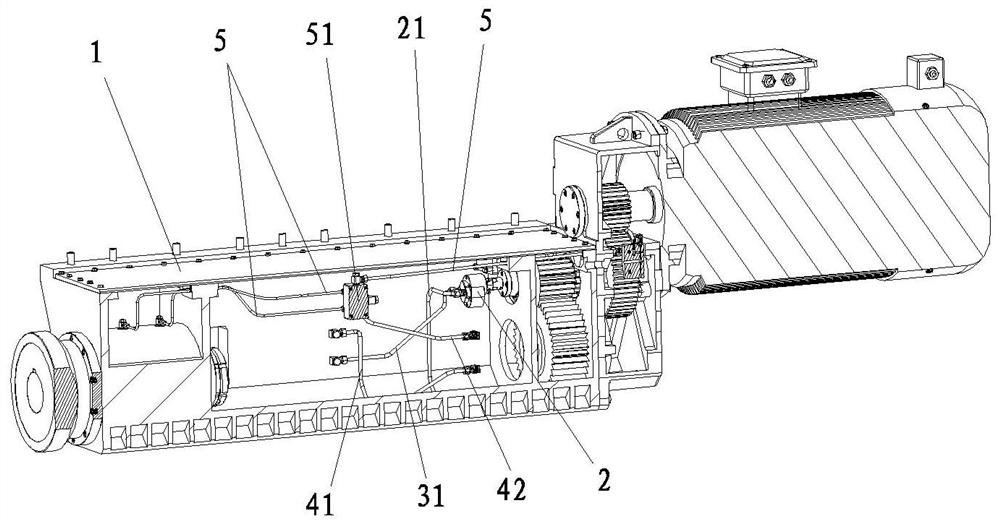

[0043] Such as Figure 1-4 As shown, a self-circulating heat-dissipating cutting machine includes a cutting machine body, and the cutting body includes a headstock 1, wherein the headstock 1 has a coolant that circulates and cools and dissipates heat from the main shaft and bearings inside the cutting machine body.

[0044] After adopting the above-mentioned structure, the coolant can directly contact with the heat-generating parts in the headstock 1, so as to speed up the heat dissipation speed and improve the heat dissipation efficiency. Moreover, the cooling liquid is self-circulating, which can save the amount of cooling liquid, reduce the pollution and consumption of cooling liquid, and greatly save the cooling cost.

[0045] Preferably, it also includes a pump 2 that provides power for the circulation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com