High-temperature-resistant cable for new energy vehicle

A new energy vehicle, high-temperature-resistant technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of affecting transmission performance and insufficient high-temperature resistance of cables, so as to improve transmission efficiency, reduce dielectric constant, and reduce dielectric loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not as limitations of the present invention.

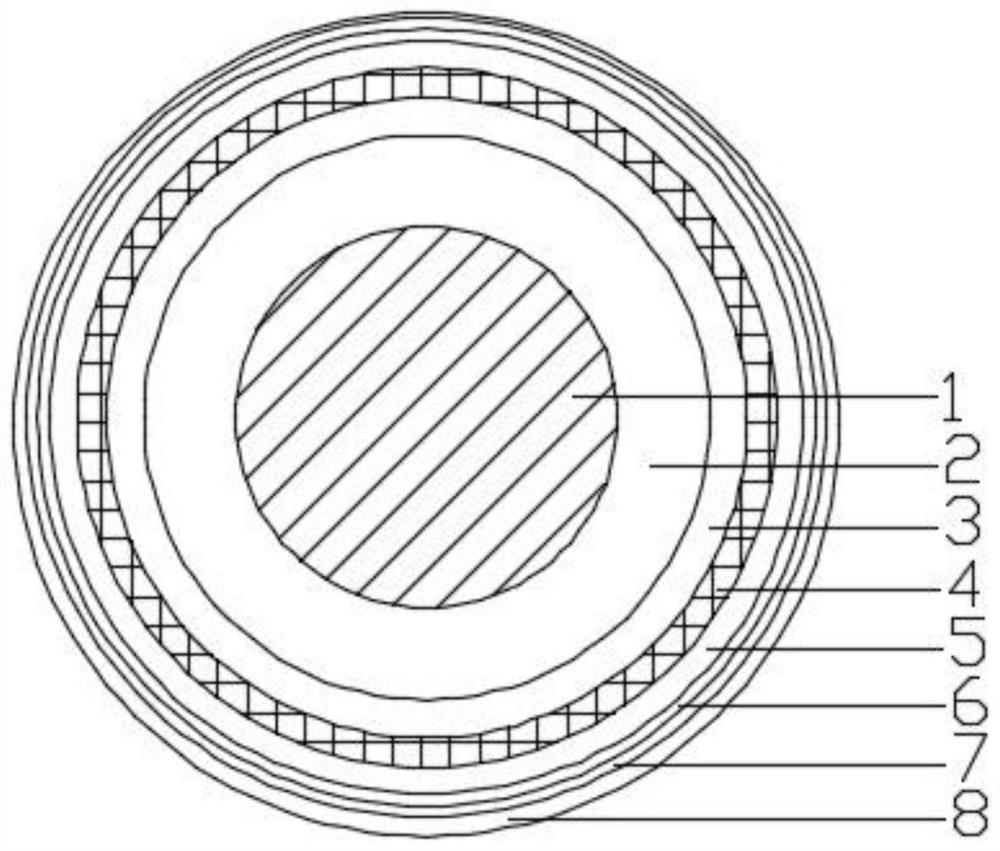

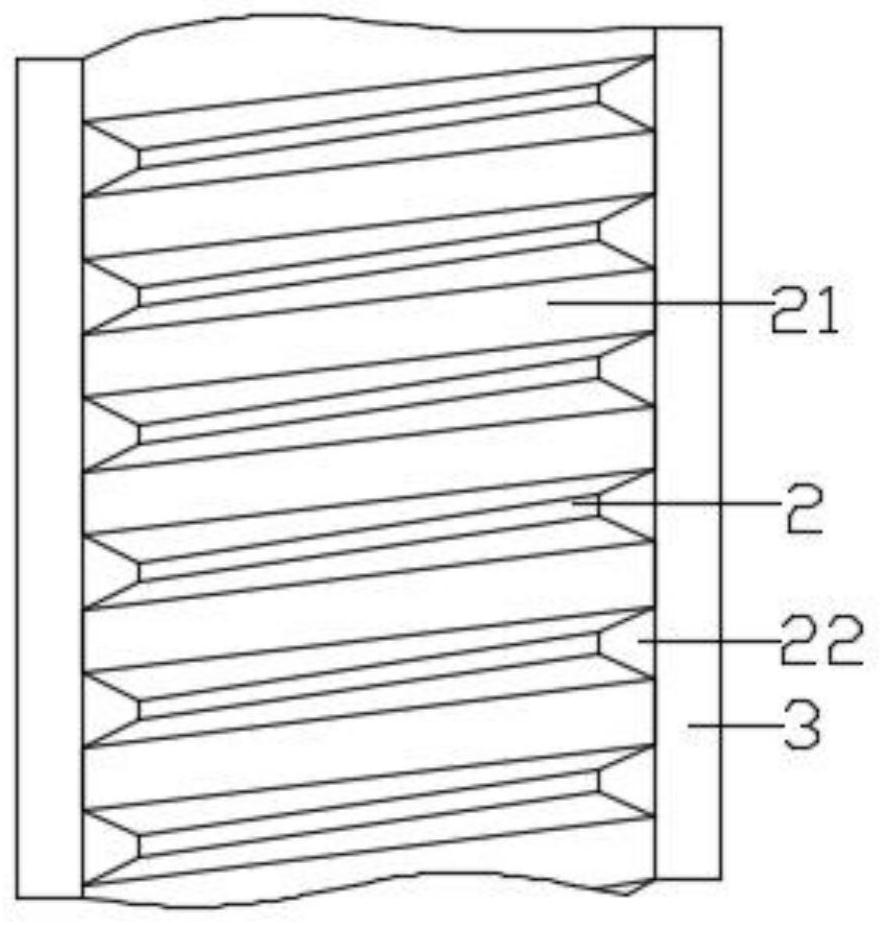

[0023] Such as Figure 1-2 As shown, the high-temperature-resistant cable for new energy vehicles in the embodiment of the present invention includes a core 1, and the core 1 is wrapped with an insulating layer 2, a photonic crystal layer 4 and a sheath layer from the inside to the outside in sequence, and the outer surface of the insulating layer 2 Threads are provided, and the pressure top 21 of the thread is in contact with the inner wall of the photonic crystal layer 4, and a cavity 22 extending along the cable axial direction is formed between the insulating layer 2 and the shielding layer 3. The cavity 22 is filled with air, and the photonic crystal The layer 4 produces a photon forbidden ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com