Laser welding method and system

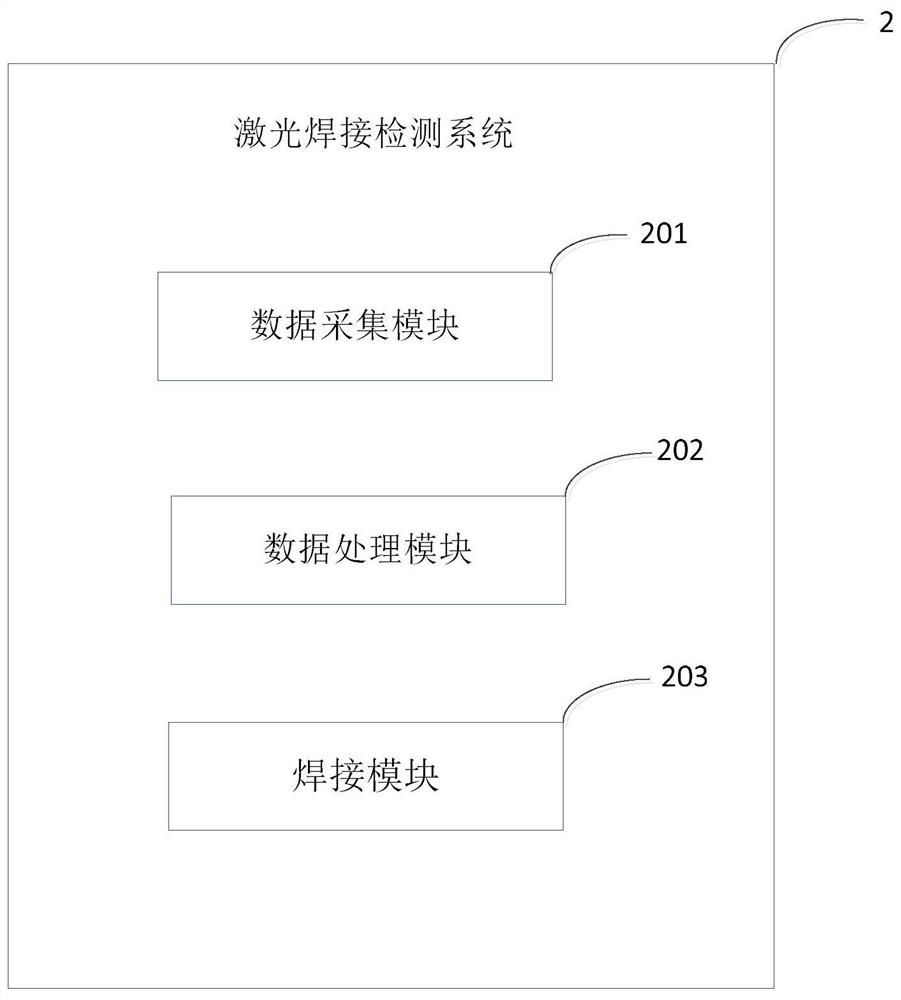

A technology of laser welding and welding points, which is applied in the field of solar cells, can solve the problems of low manual welding operation efficiency and good product rate, affecting battery production efficiency, etc., and achieve the effect of improving operation efficiency and good product rate, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] The present invention will be specifically described below in conjunction with a specific embodiment, but it should be noted that this specific embodiment is only for better describing the present invention, and does not constitute an improper limitation of the present invention.

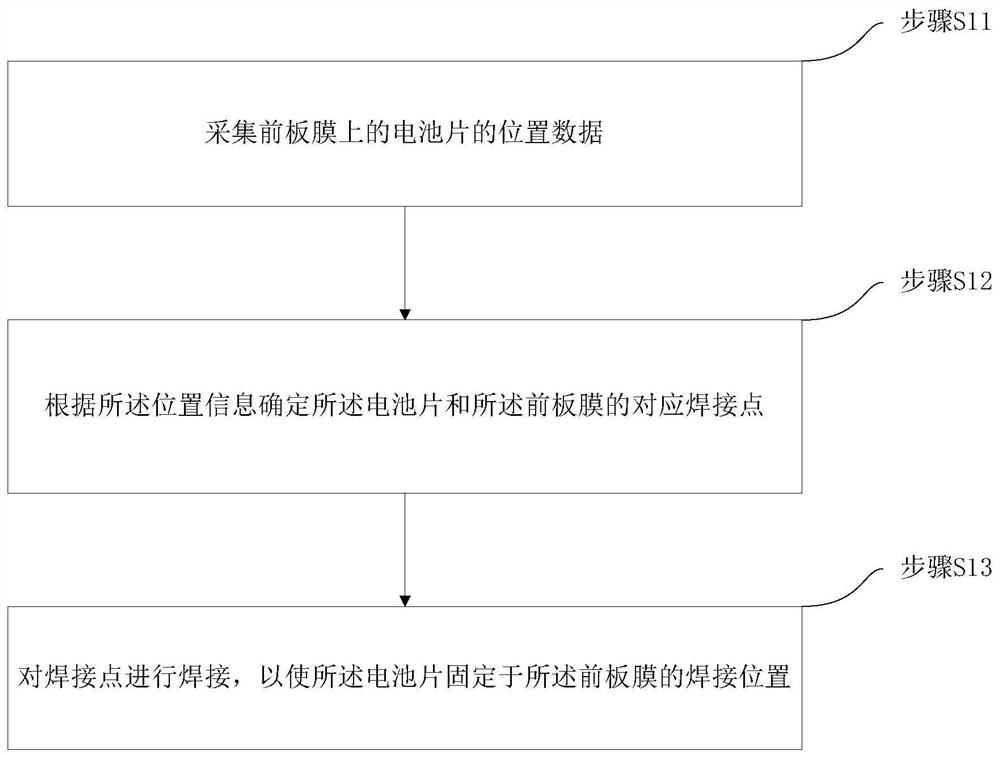

[0049] First, fix the battery sheet on the front panel film, use the image acquisition device to take pictures of the battery sheet and the front panel film and collect the image data of the battery sheet and the front panel film.

[0050] Then, according to the image data of the battery sheet and the front sheet film, set the "cross mark" on the front sheet film, so that the "cross mark" can be used as the marking point to determine the welding point of the cell sheet and the front sheet film. In particular, the welding area is cross-shaped or S-shaped, and there may be multiple welding points, which are arranged sequentially on the same side of the battery sheet and the front plate film.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com