Power assembly suspension with variable three-way rigidity and adjustable height and limiting distance

A powertrain and assembly technology, which is applied to power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve problems such as affecting the vibration isolation performance of mounts, affecting riding comfort, affecting R&D efficiency and quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

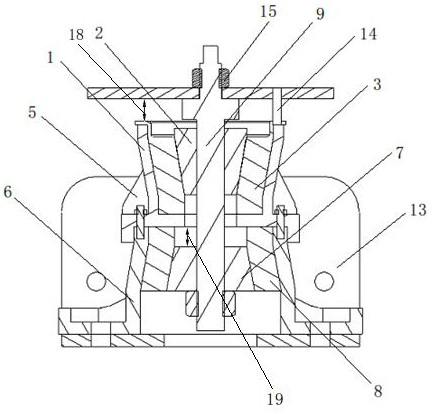

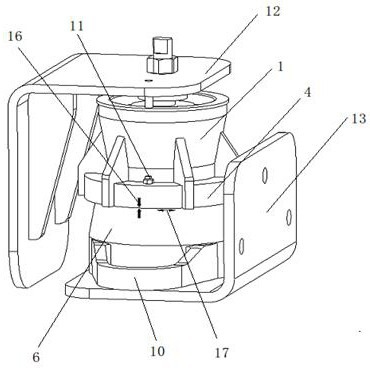

[0017] Below in conjunction with accompanying drawing, the present invention is further described in detail:

[0018] The invention relates to a buffer device for a power assembly, in particular, a power assembly suspension device with variable stiffness in three directions and adjustable height and limit spacing. The present invention includes two parts, an upper suspension assembly and a lower suspension assembly, and the upper suspension and the lower suspension are fixed by screw threads arranged on the edges of the two. Part 4, the inner surface of the door type part 4 is provided with threads, and the upper edge of the lower suspension assembly is provided with threads corresponding to the door type part 4, so that the upper suspension assembly and the lower suspension assembly can pass through the threads The rotary connection is integrated, and the relative height of the two can be adjusted according to how much the threads are screwed in.

[0019] In the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com