Tire centering device and method

A centering device and tire technology, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve problems such as falling off, unable to meet the normal input of processing equipment, inconvenient tire fixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

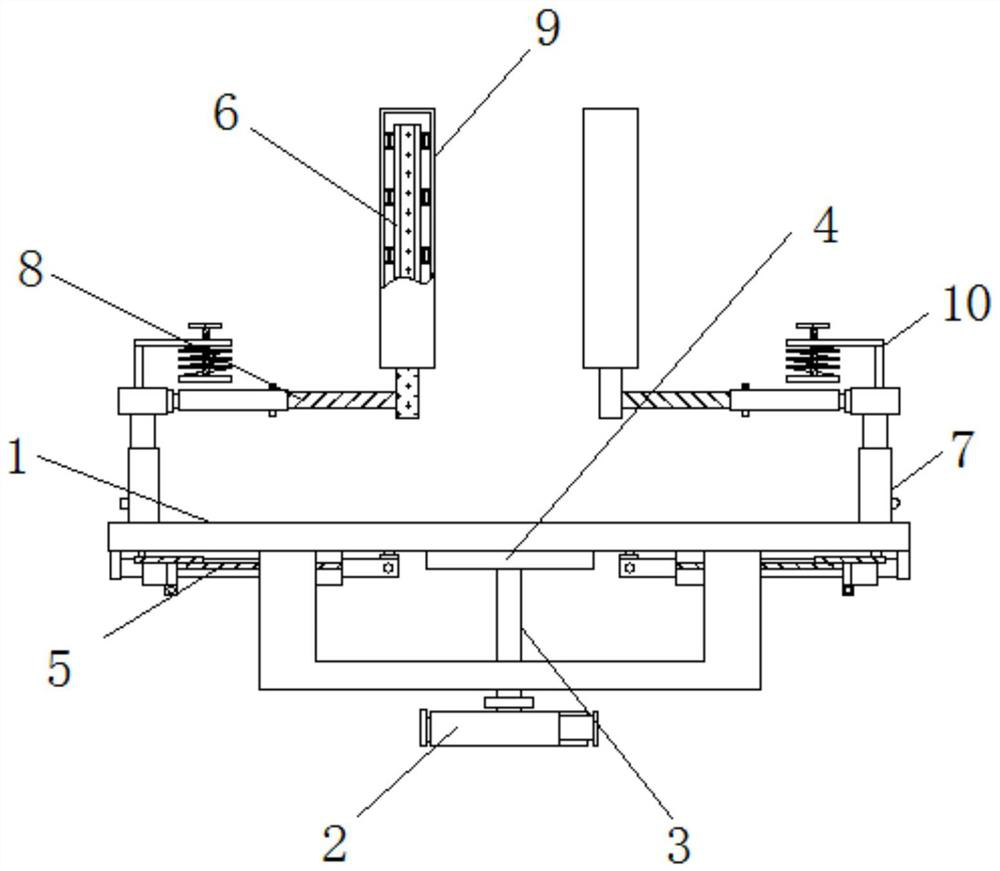

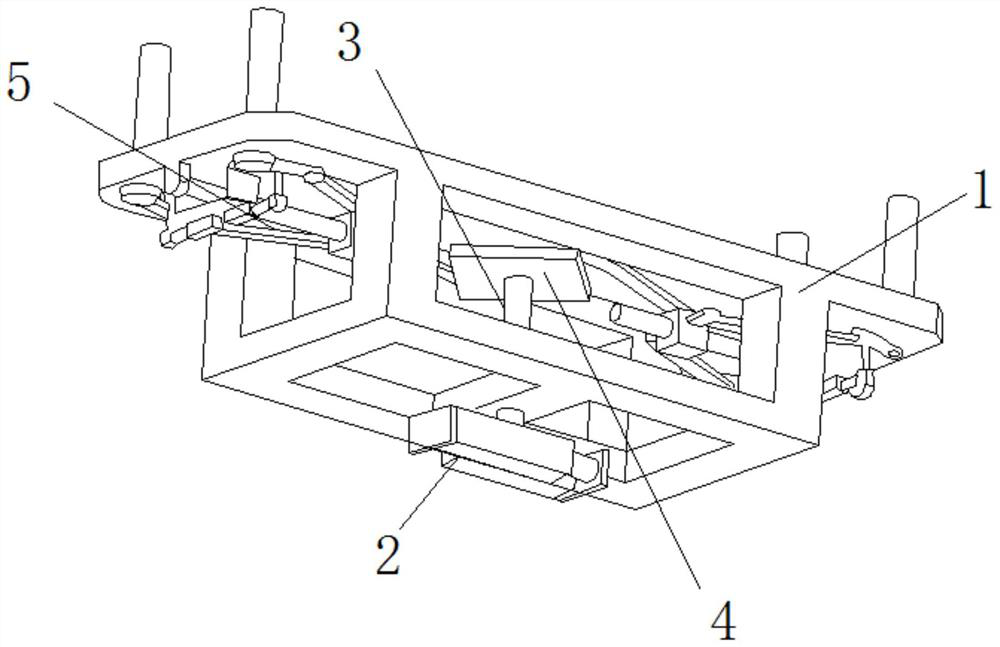

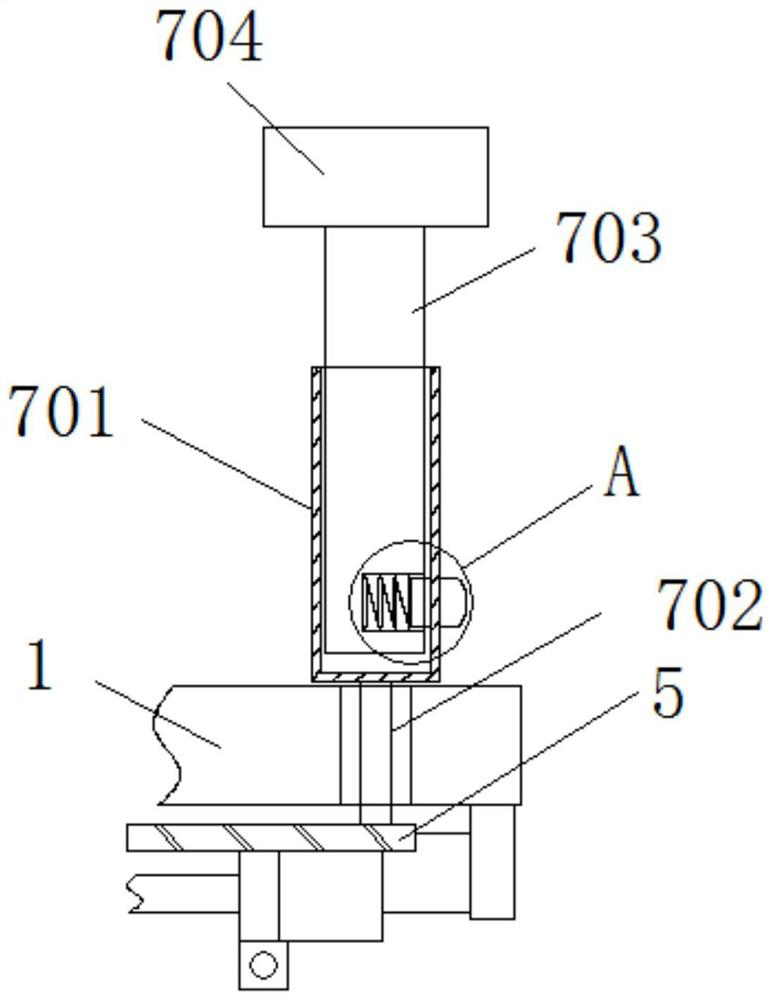

[0049] The present invention provides such Figure 1-7The tire centering device shown includes a mounting frame 1, a cylinder 2 is fixedly installed at the bottom of the mounting frame 1, and a rotating rod 3 is fixedly connected to the top of the cylinder 2, and the rotating rod 3 passes through the bottom end of the mounting frame 1 and is welded to a The center turntable 4, the two sides of the center turntable 4 are fixedly connected with the connecting rod module 5, the upper end of the installation frame 1 is installed with four claws 6, the top of the installation frame 1 is installed with a lifting adjustment mechanism 7, and the inside of the lifting adjustment mechanism 7 includes and installs The telescopic outer rod 701 is movably connected around the top of the frame 1, the bottom end of the telescopic outer rod 701 is welded and connected with a connecting rod 702, the connecting rod 702 is fixedly connected with the connecting rod module 5, and the telescopic out...

Embodiment 2

[0052] Specific as Figure 3-4 As shown, the connecting rod 702 is movably socketed with the top of the installation frame 1, and one side of the telescopic outer rod 701 is equidistantly provided with through holes.

[0053] It should be further explained that the telescopic outer rod 701 is fixedly connected to the rotating part of the link module 5 through the connecting rod 702 , and the telescopic outer rod 701 rotates coaxially with the rotating part of the link module 5 .

[0054] Specific as Figure 5 As shown, the interior of the distance adjustment mechanism 8 includes a rotating shaft 801 fixedly connected to one side of the connecting block 704, the other end of the rotating shaft 801 is rotatably connected to a sleeve 802, and the sleeve 802 is internally threaded with a threaded rod 803, and the threaded rod 803 and One side of the claw 6 is welded, and a pin 804 is inserted between the sleeve 802 and the threaded rod 803 .

[0055] It should be further explain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com