Environment-friendly treatment method of garbage penetrating fluid

A technology of garbage permeate and treatment method, which is applied in the field of environmentally friendly treatment of garbage permeate, and can solve problems such as inconvenient filtration, uneven aeration, and blockage of aeration pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

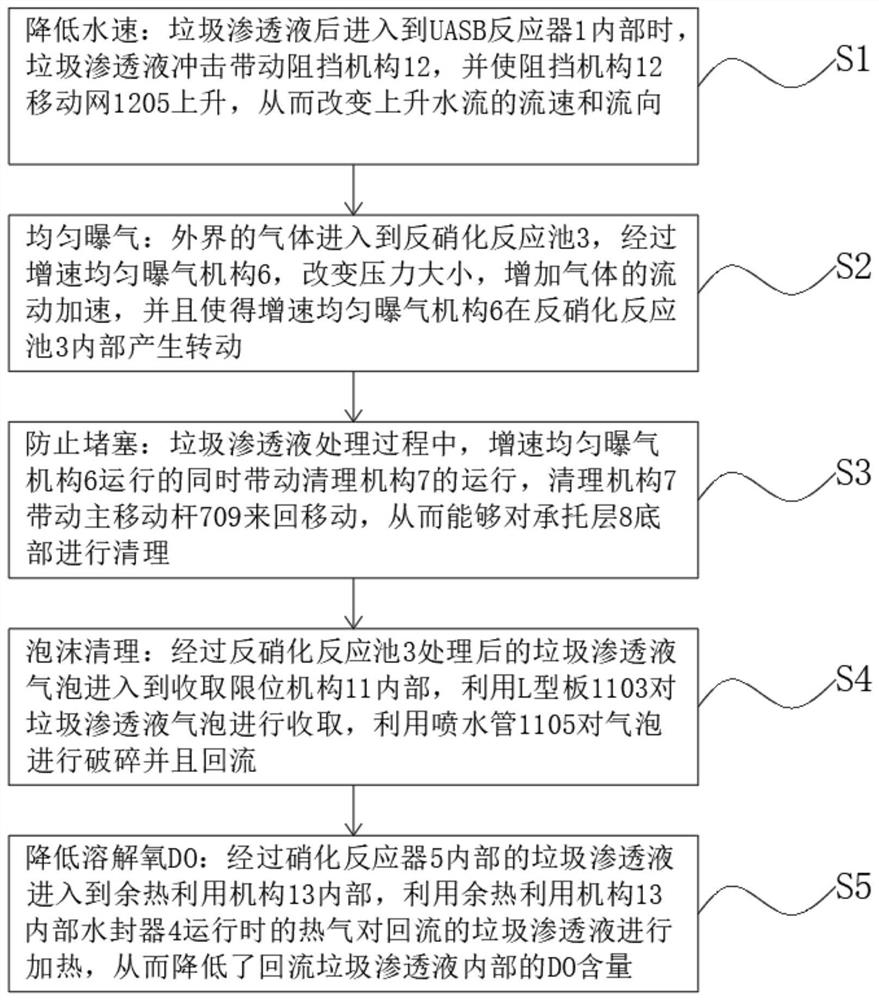

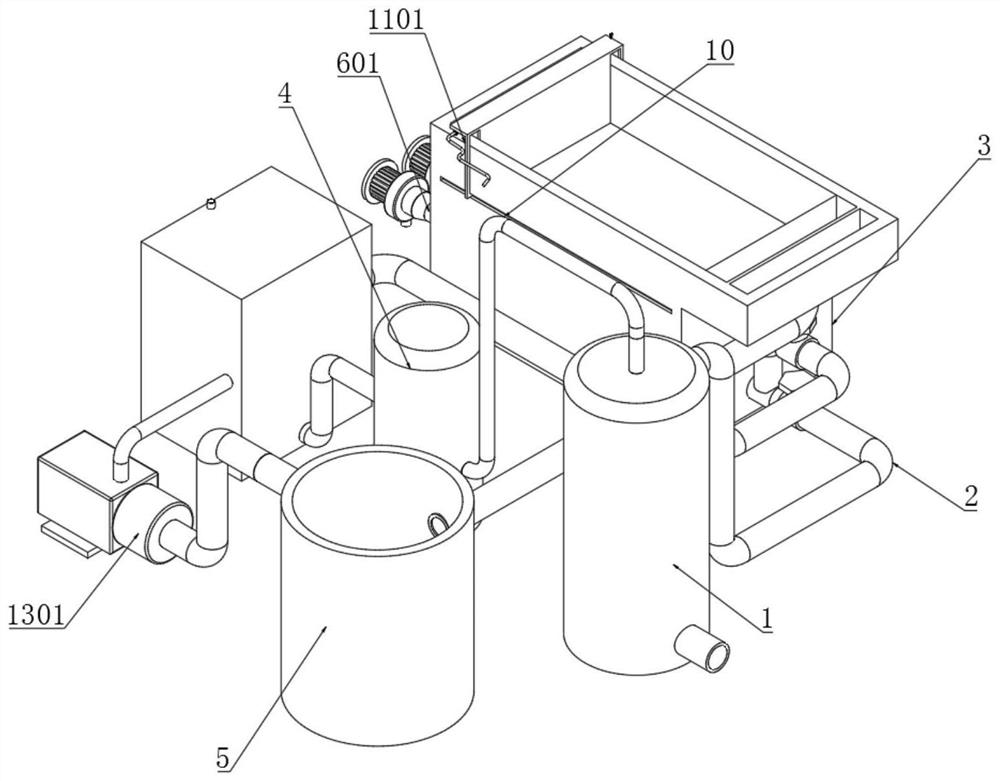

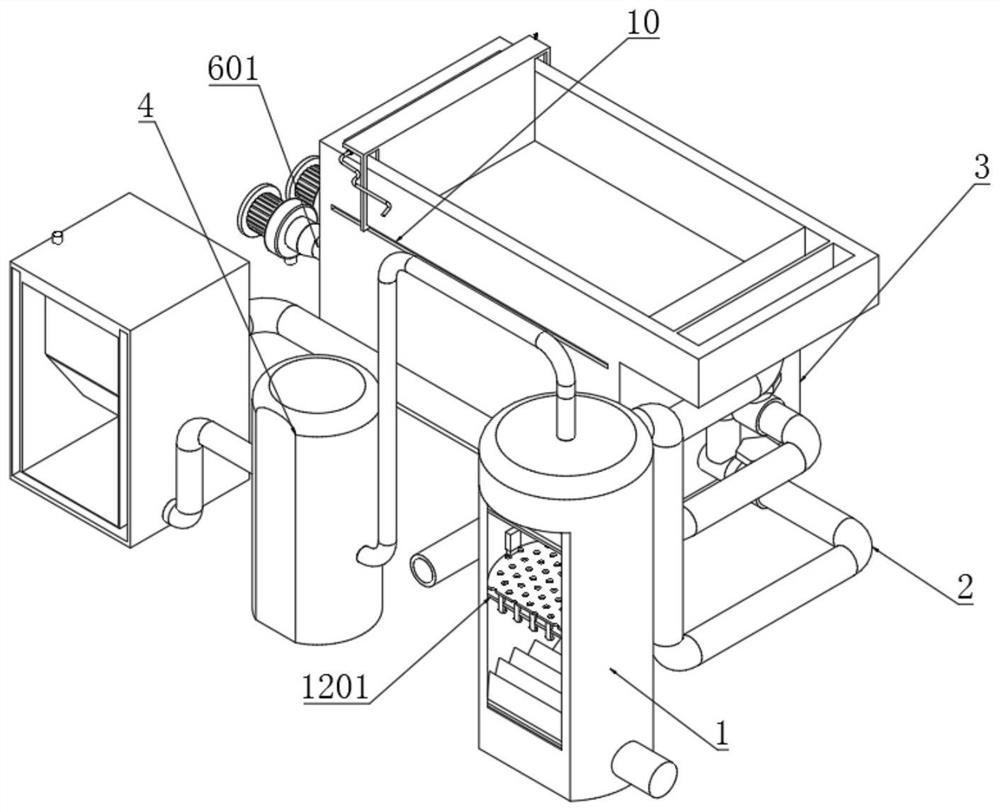

[0042] Example: such as figure 1 As shown, the present invention provides a technical solution, an environmentally friendly treatment method for garbage permeate, comprising the following steps;

[0043] S1: Reduce the water velocity: when the garbage seepage liquid enters the UASB reactor 1, the garbage seepage liquid impacts and drives the blocking mechanism 12, and makes the blocking mechanism 12 move the net 1205 up, thereby changing the flow velocity and direction of the rising water flow;

[0044] S2: Uniform aeration: The outside gas enters the denitrification reaction tank 3, passes through the speed-up uniform aeration mechanism 6, changes the pressure, increases the flow acceleration of the gas, and makes the speed-up uniform aeration mechanism 6 in the denitrification reaction tank 3 internal rotation;

[0045] S3: Prevent clogging: During the process of garbage permeate treatment, the speed-up uniform aeration mechanism 6 operates and drives the operation of the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com