A method for synergistically cleaning oil-based mud by using cloud point and in-situ emulsification and a matching cleaning agent

A cleaning agent and cleaning oil technology, applied in the directions of detergent compounding agents, chemical instruments and methods, detergent compositions, etc., to achieve the effects of good temperature resistance, improved cleaning effect, and increased solubilization amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

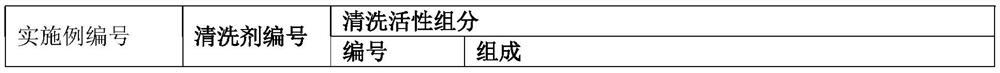

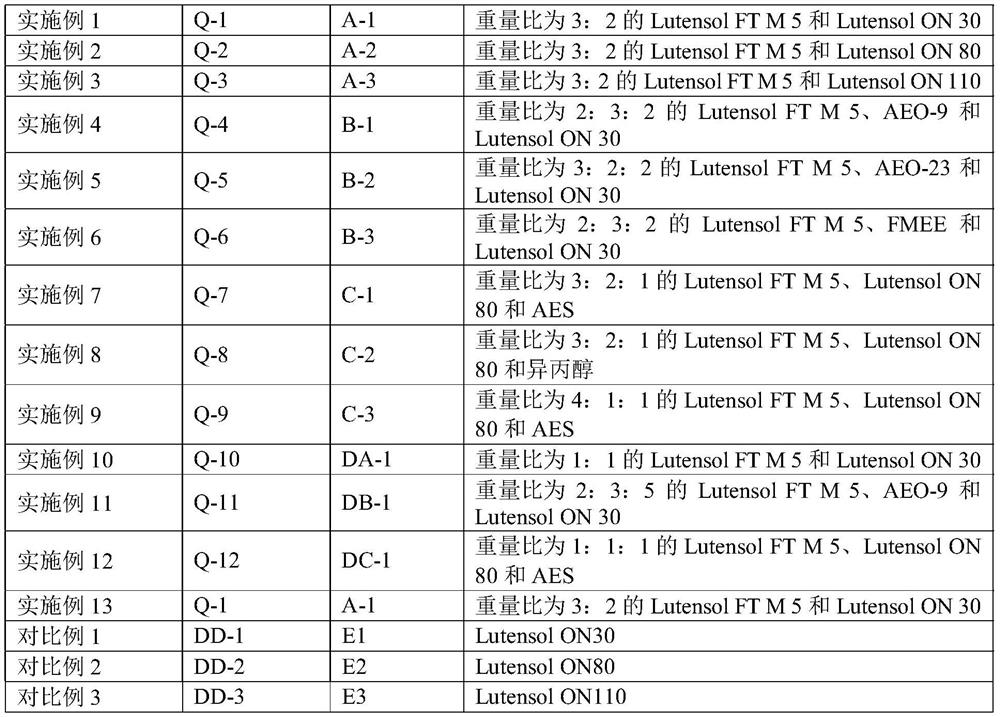

[0043] In the cleaning agent, the first nonionic surfactant is Lutensol FT M 5, and the second nonionic surfactant is selected from at least one of Lutensol ON 30, Lutensol ON 80 and Lutensol ON 110.

[0044] In the cleaning agent provided in Embodiment 1, the content weight ratio of the first nonionic surfactant to the second nonionic surfactant is 1:0.25-0.67.

specific Embodiment approach 2

[0046]In the cleaning agent, the first nonionic surfactant is Lutensol FT M 5, the second nonionic surfactant is Lutensol ON 80, and the cloud point enhancer is selected from fatty alcohol polyoxyethylene ether sodium sulfate at least one of them. In a particularly preferred case, the fatty alcohol polyoxyethylene ether sodium sulfate described in the present invention is the fatty alcohol polyoxyethylene ether sodium sulfate mixture provided by BASF.

[0047] In the cleaning agent provided in Embodiment 2, the content weight ratio of the first nonionic surfactant, the second nonionic surfactant and the cloud point improver is 1:0.25-0.67:0.25 -0.33.

[0048] The inventors found that the cleaning agent provided in the above preferred embodiments has higher solubilization amount of wellbore oil pollution and better cleaning effect of oil pollution.

[0049] In the present invention, there is no strict requirement for the water phase, which can be deionized water, distilled wa...

specific Embodiment approach

[0059] In the present invention, according to a preferred embodiment, the method for synergistically cleaning oil-based mud by cloud point and in-situ emulsification comprises the following steps:

[0060] (1) The cleaning agent described in the first aspect is transported to the bottom of the well to be cleaned, and the cloud point temperature of the cleaning agent is not higher than the temperature of the bottom of the well;

[0061] (2) soaking the downhole oily casing and / or the well wall in the cleaning agent for 5-20min and flushing for 5-15min to obtain a cleaning solution containing oily dirt;

[0062] (3) Return the oil-containing cleaning fluid to the wellhead.

[0063] In the present invention, the cleaning agent is directly transported to the bottom of the well to be cleaned without pre-preparing into a micro-emulsion or a nano-emulsion, avoiding the pre-incorporation of the oil phase, and improving the solubilization amount of oil pollution in the wellbore.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com