A kind of lidocaine microemulsion gel and preparation method thereof

A lidocaine and microemulsion gel technology, which is applied in the directions of pharmaceutical formulations, emulsion delivery, medical preparations of inactive ingredients, etc., can solve the problem of low drug loading, microemulsion surfactant and cosurfactant dosage large, safety and effectiveness need to be improved to achieve the effect of increasing the amount of solubilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

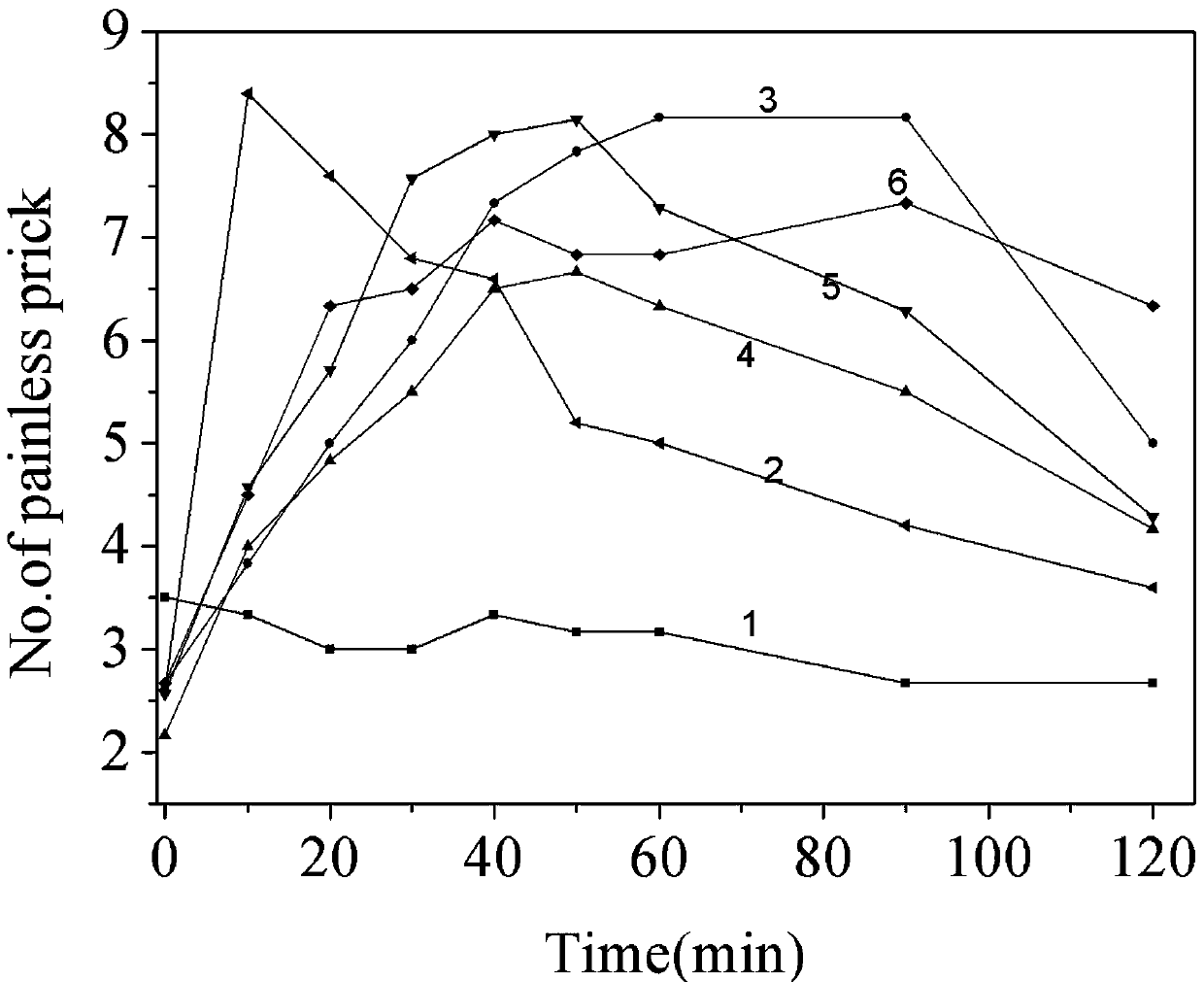

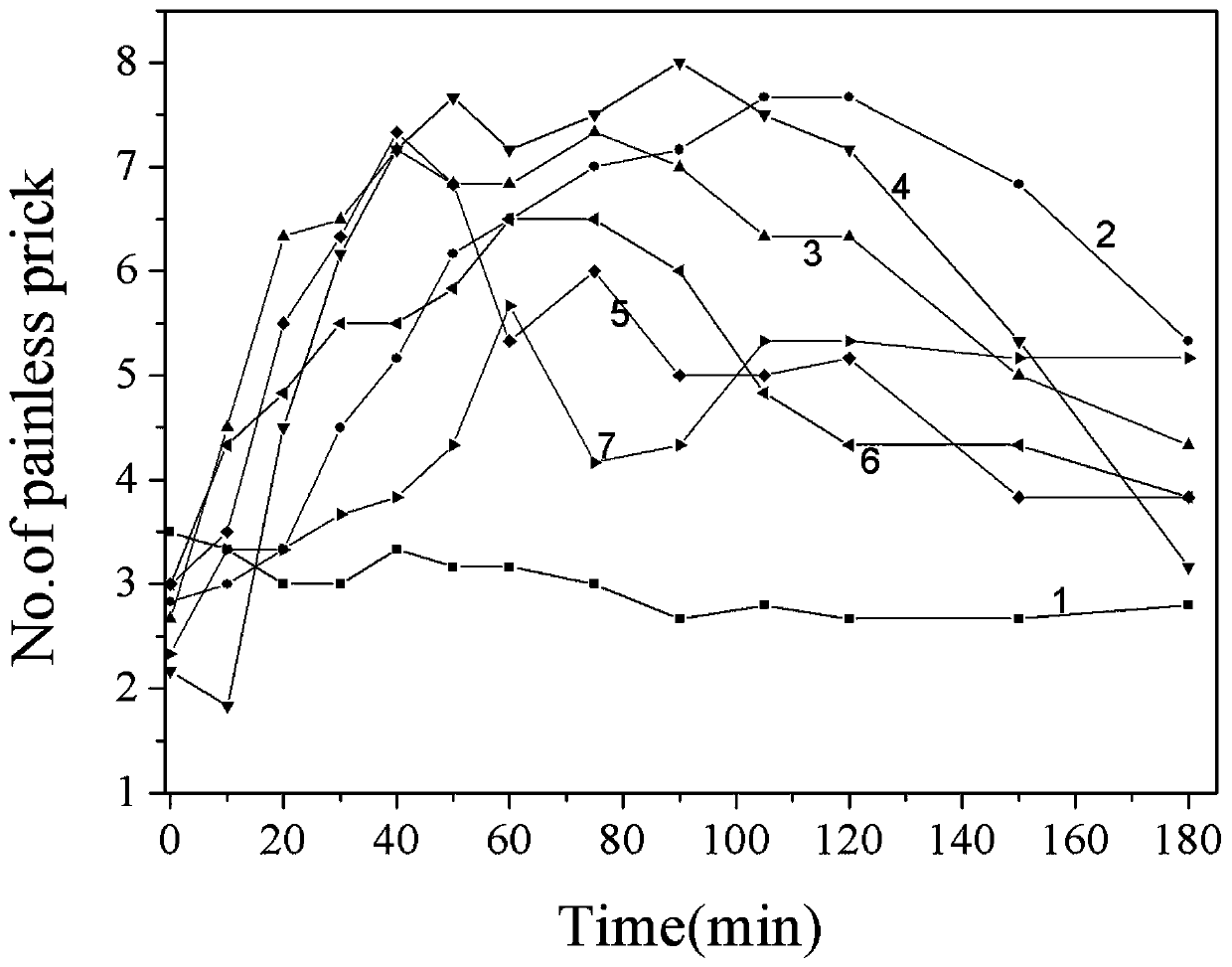

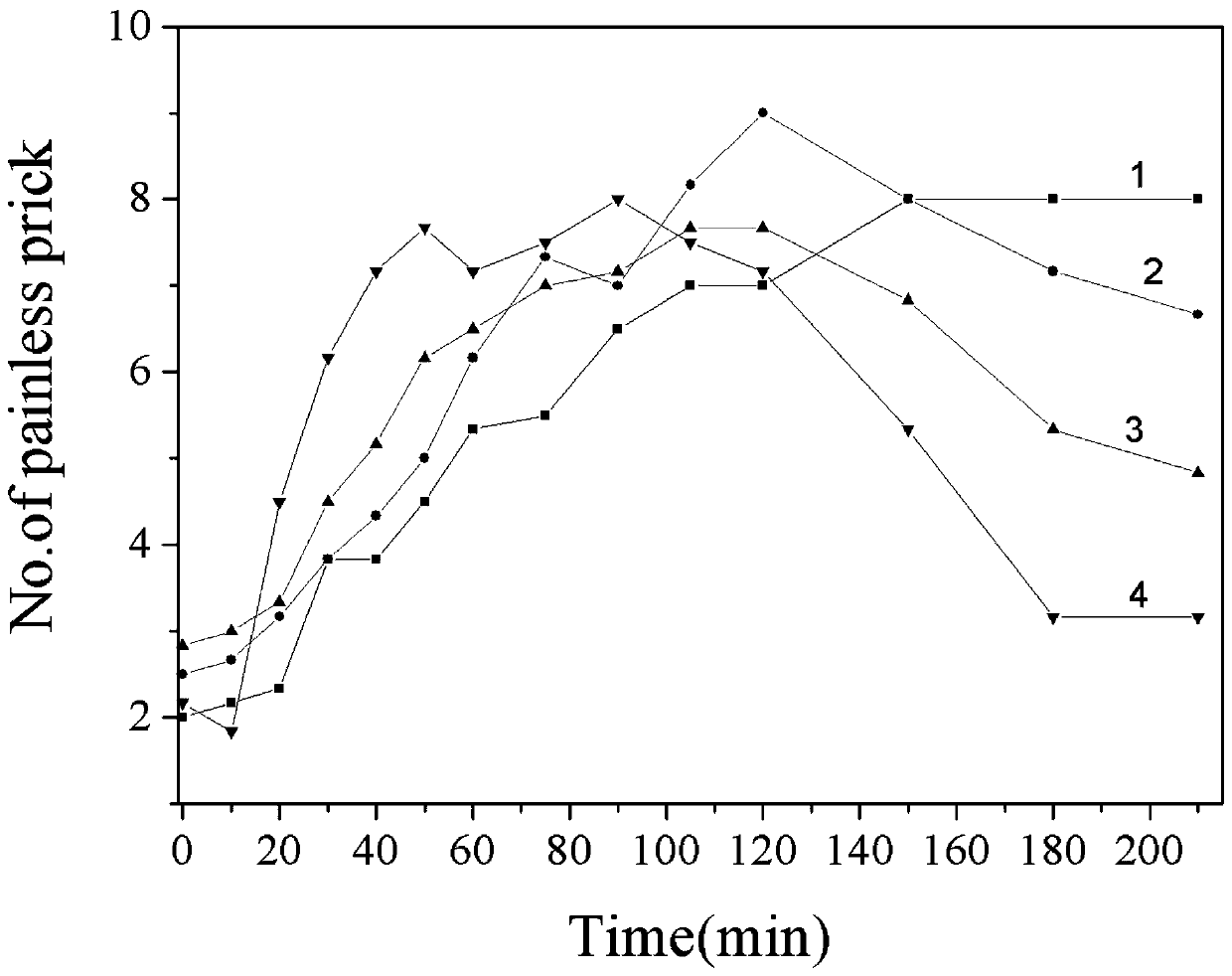

Embodiment 1

[0020] Example 1 Dissolve 2g of lidocaine in a mixture of 3.75g of olive oil and vitamin E succinate (mass ratio 6:1) at 70°C, and add 8.75g of surfactant (polyoxyethylene hydrogenated Castor oil and Span 80 are mixed at a mass ratio of 5:1), and then the required amount of distilled water is added drop by drop under stirring to form a microemulsion. After adding 0.1g of preservative (sodium methylparaben and sodium propylparaben mixed at a mass ratio of 1:1), let it stand to cool to room temperature, then sprinkle 0.4g of Carbomer 980, fully After swelling, stir, degas, and sterilize to prepare 100 g of lidocaine microemulsion gel with a concentration of 2%.

Embodiment 2

[0021] Example 2 4g of lidocaine was dissolved in 3.75g of olive oil and vitamin E succinate (mass ratio 6:1) mixed oil at 70°C, and 8.75g of surfactant (polyoxyethylene hydrogenated Castor oil and Span 80 are mixed at a mass ratio of 5:1), and then the required amount of distilled water is added drop by drop under stirring to form a microemulsion. After adding 0.1g of preservative (sodium methylparaben and sodium propylparaben mixed at a mass ratio of 1:1), let it stand to cool to room temperature, then sprinkle 0.4g of Carbomer 980, fully After swelling, stir, degas, and sterilize to obtain 100 g of lidocaine microemulsion gel with a concentration of 4%.

Embodiment 3

[0022] Example 3 5g of lidocaine was dissolved in 3.75g of olive oil and vitamin E succinate (mass ratio 6:1) mixed oil at 70°C, and 8.75g of surfactant (polyoxyethylene hydrogenated Castor oil and Span 80 are mixed at a mass ratio of 5:1), and then the required amount of distilled water is added drop by drop under stirring to form a microemulsion. After adding 0.1g of preservative (sodium methylparaben and sodium propylparaben mixed at a mass ratio of 1:1), let it stand to cool to room temperature, then sprinkle 0.4g of Carbomer 980, fully After swelling, stir, degas, and sterilize to obtain 100 g of lidocaine microemulsion gel with a concentration of 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com