Intelligent slip casting machine for hydrodynamic rupture zone

A broken belt and grouting machine technology, which is applied in building maintenance, infrastructure engineering, construction, etc., can solve the problems of easy shaking and displacement of equipment, affecting use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

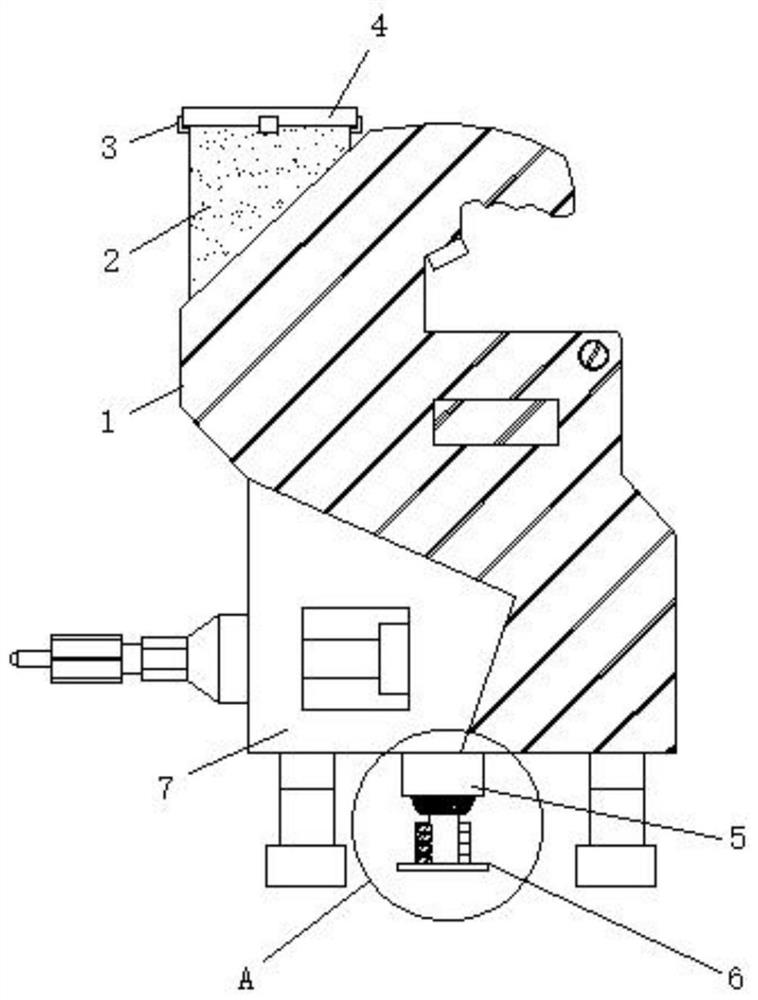

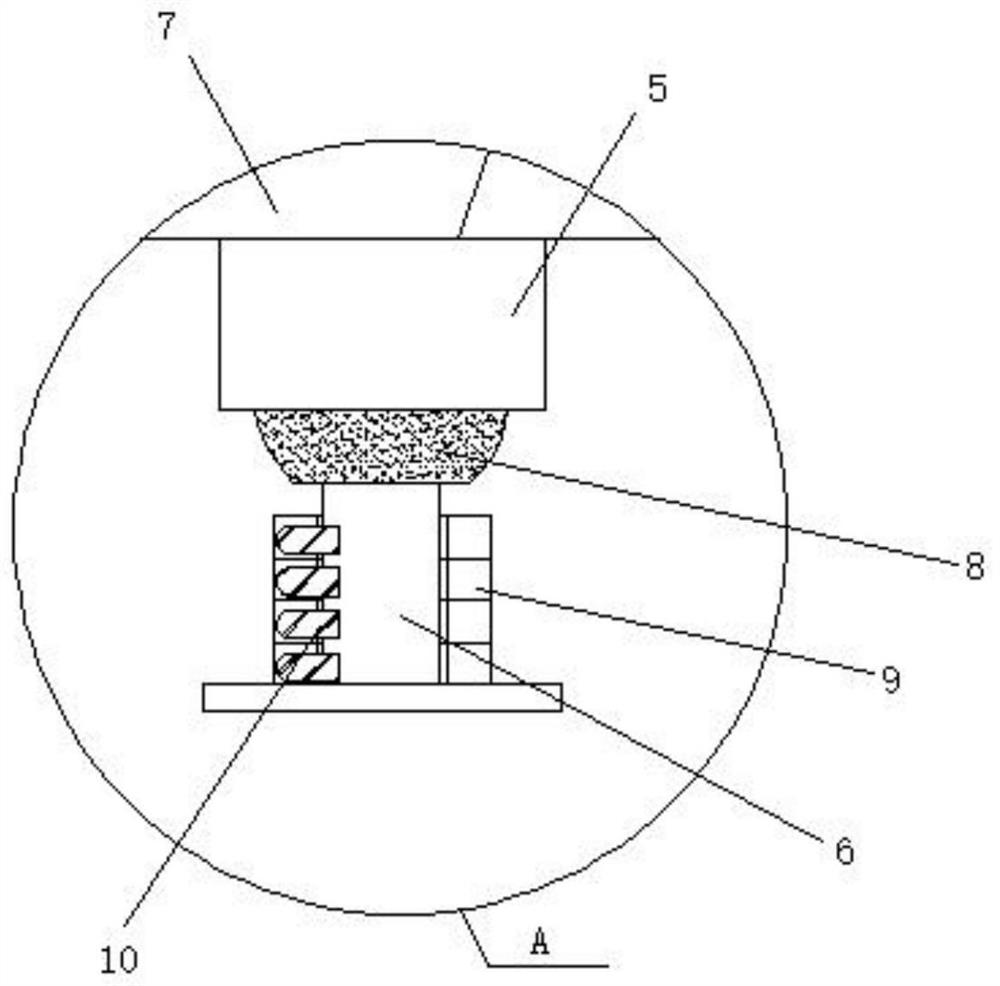

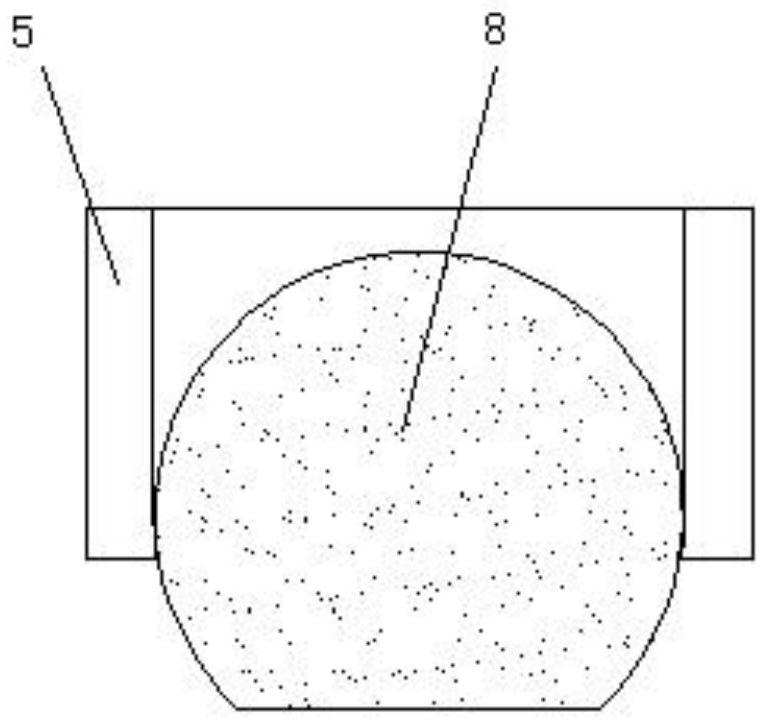

[0021] see Figure 1 to Figure 4 , the present invention provides a technical solution: an intelligent grouting machine for dynamic water crushing belt, including a body 7, a casing 1 is set outside the body 7, a bottom block 5 is fixed at the center of the bottom end of the body 7, and the inside of the bottom block 5 is Balls 8 are provided, and through the design of balls 8, according to the inclination of its body, the bottom frame 6 can be adjusted at multiple angles, thereby ensuring the maximum weight of the weight block 9. The bottom of the balls 8 is fixed with the bottom frame 6, and the bottom The surface of the frame 6 is provided with a load-bearing block 9. Through the designed load-bearing block 9, gravity is applied to the present invention, thereby increasing its total weight, making it less prone to vibration and displacement. The inside of the bottom block 5 is a hollow structure, and the ball 8 is located inside the bottom block 5 It can roll freely, and th...

Embodiment 2

[0023] see Figure 1 to Figure 4 , the present invention provides a technical solution: an intelligent grouting machine for dynamic water crushing belt, including a body 7, a casing 1 is set outside the body 7, a bottom block 5 is fixed at the center of the bottom end of the body 7, and the inside of the bottom block 5 is Balls 8 are provided, and through the design of balls 8, according to the inclination of its body, the bottom frame 6 can be adjusted at multiple angles, thereby ensuring the maximum weight of the weight block 9. The bottom of the balls 8 is fixed with the bottom frame 6, and the bottom The surface of the frame 6 is provided with a load-bearing block 9. Through the designed load-bearing block 9, gravity is applied to the present invention, thereby increasing its total weight, making it less prone to vibration and displacement. The inside of the bottom block 5 is a hollow structure, and the ball 8 is located inside the bottom block 5 It can roll freely, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com