Novel air filter with disinfection and sterilization functions and method

An air filter, disinfection and sterilization technology, applied in the direction of air quality improvement, heating methods, home appliances, etc., can solve problems such as hidden safety hazards in the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

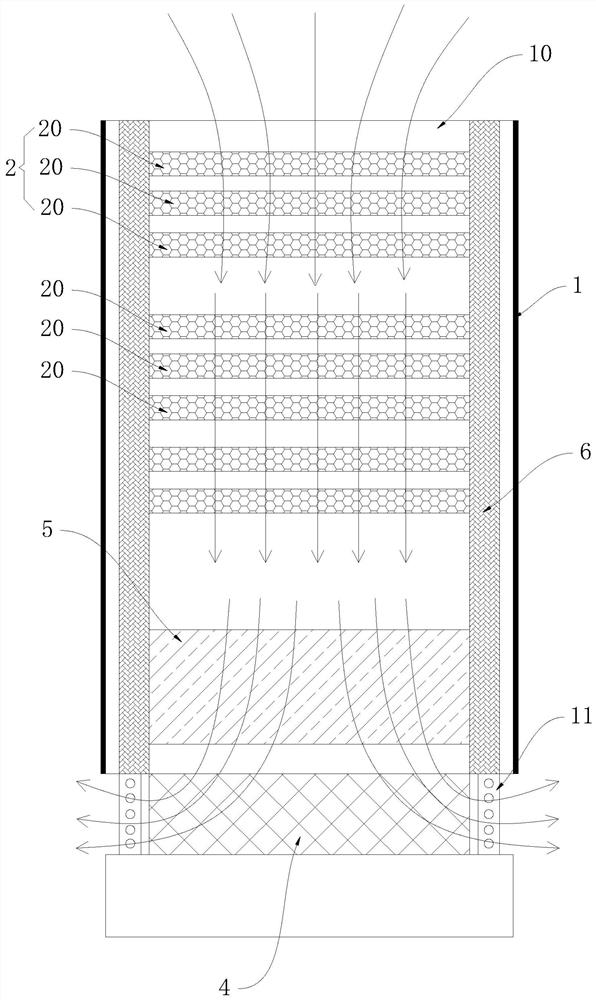

[0023] This embodiment proposes a new type of air filter with disinfection and sterilization functions, please refer to figure 1 , It includes an organic casing 1, the casing 1 is provided with an air inlet 10 and an air outlet 11, the casing 1 is provided with a heating filter unit 2 and a fan 4, the air inlet 10, the heating filter The unit 2, the fan 4 and the air outlet 11 are connected in sequence. When the fan 4 is in operation, air is drawn in through the air inlet 10, and the heated filter unit 2 performs high-temperature sterilization on the drawn air And filtering, and then discharged from the air outlet 11.

[0024] In the above-mentioned filter, a heating filter unit 2 and a fan 4 are arranged in the casing 1, and the fan 4 mainly plays a role of driving air circulation. On this basis, the present invention is arranged near the air inlet 10 Heating filter unit 2, when the fan 4 extracts air flow, the sucked air first enters the heating filter unit 2. Under the high te...

Embodiment 2

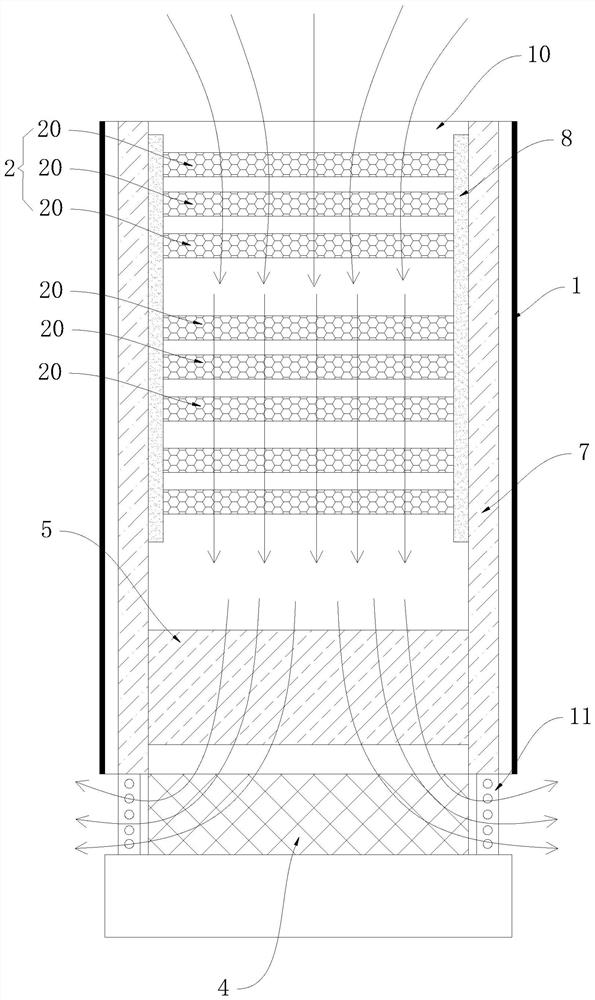

[0037] See figure 2 The difference between this embodiment and the first embodiment is mainly the replacement of the heat insulation layer. As an alternative, in this embodiment, a refrigeration layer 7 is provided on the inside of the casing 1, and the refrigeration layer 7 covers the outside of the heating and filtering unit 2, and the refrigeration tube of the evaporator extends to Inside the refrigeration layer 7.

[0038] This embodiment is preferably provided with a refrigeration layer 7 capable of actively cooling and cooling. The refrigeration layer 7 can better block the heat inside the casing. At the same time, the refrigeration layer 7 and the evaporator use the same refrigeration tube, and there is no need In addition, the evaporator is configured to help save equipment costs.

[0039] In order to avoid adverse effects on the heating and filtering unit 2 during the cooling process, in this embodiment, the outer side of the heating and filtering unit 2 is covered with ...

Embodiment 3

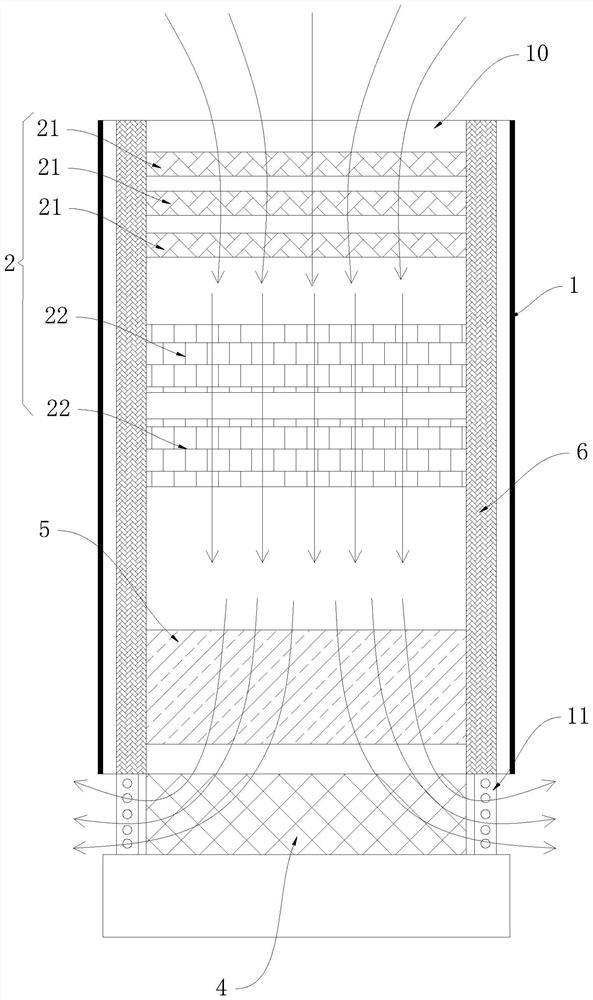

[0041] See image 3 The difference between this embodiment and the first and second embodiments is that this embodiment can use a common electric heater and a common air filter to form the heating filter unit 2, which specifically refers to:

[0042] In this embodiment, the heating filter unit 2 includes an electric heater 21 and an air filter unit 22, the electric heater 21 is close to the air inlet 10, and the air filter unit 22 is provided on the electric heater. The device 21 and the cooling unit 5 or is provided on the output side of the cooling unit 5.

[0043] In the above structure, the electric heater 21 may be a device such as an electric heating tube, and the air filter unit 22 may be an air filter element. In this embodiment, the combination of the electric heater 21 and the air filter unit 22 can achieve high-temperature air destruction. As well as the filtering function, at the same time, in order to prevent the hot air from causing adverse effects on the air filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com