Torque flange calibration device

A calibration device and torque method technology, applied in measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve the problems of poor practicability and low precision in field operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments.

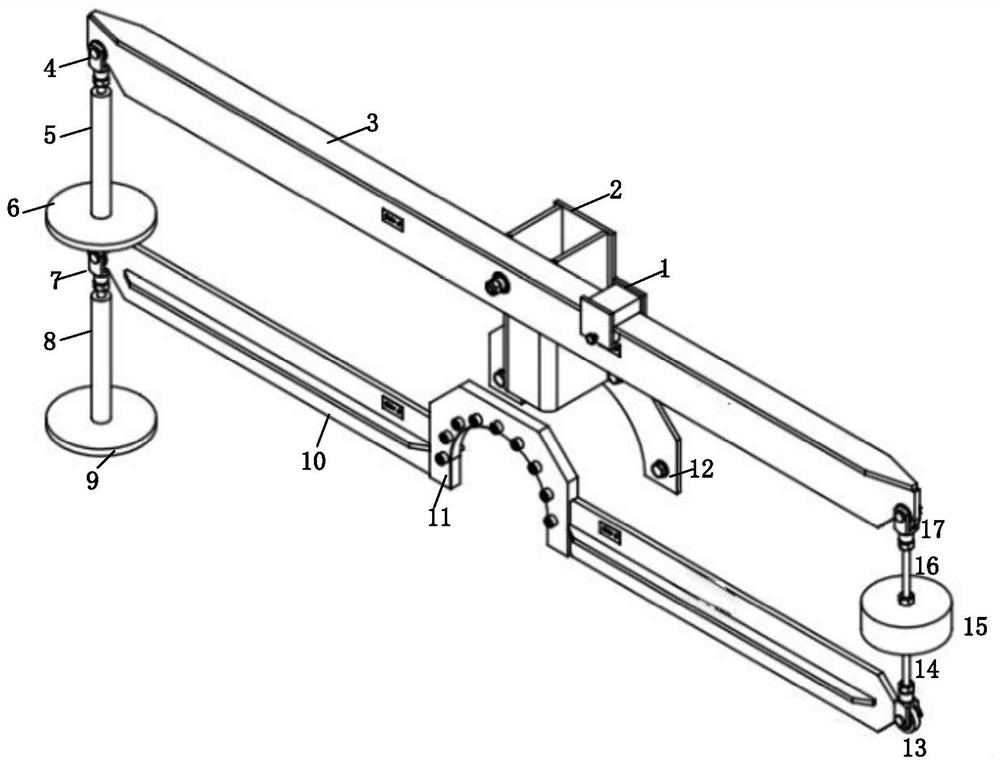

[0028] from figure 1 It can be seen that the torque flange calibration device in this embodiment is mainly composed of an adjustment weight 1, an upper arm support 2, an upper arm 3, an upper arm weight support 5, an upper arm weight tray 6, and a lower arm weight support 8. The lower arm weight tray 9, the lower arm 10, the lower arm adjustment block strut 14, the adjustment block 15, and the upper arm adjustment block strut 16 are composed. Wherein the upper arm 3 and the lower arm 10 can be telescopic arms, and the length of the arms can be adjusted according to different amounts of stroke torque flanges. The axial center of the lower arm 10 is provided with a torque flange adapter 11. It can also be understood that the lower arm 10 is two equal-length arms, and the two equal-length arms are respectively welded on the torque flange adapter 11. on both sides. The struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com