A fault handling method for the speed measuring motor in the ssb pitch motor

A fault handling method and a tachometer motor technology, which are applied in the field of wind power, can solve the problems of long workload and working time, high cost of spare parts for pitch motors, waste of spare parts cost, etc., so as to reduce the cost of spare parts and reduce the workload and working time. , reduce the effect of lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

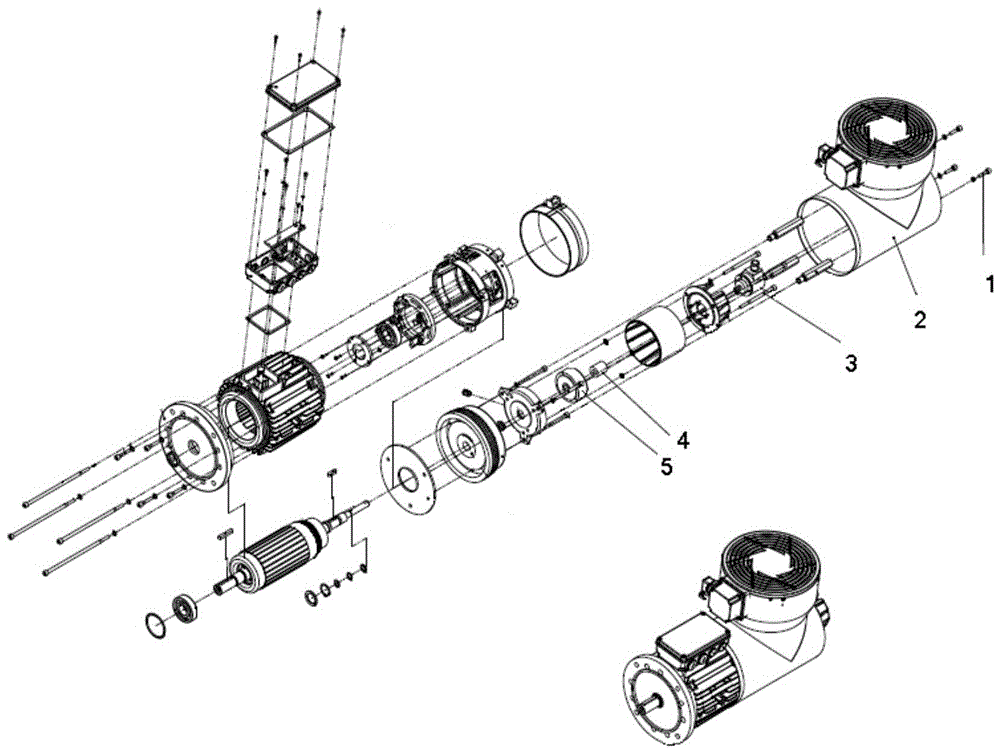

[0035] The invention provides a fault handling method for a speed-measuring motor of an SSB variable-pitch motor, that is, the speed-measuring motor is replaced separately.

[0036] With the prolongation of the running time of the unit, the speed measuring motor in the SSB pitch motor will have a certain degree of wear or abnormal output, which will cause the feathering speed of the pitch motor to be too fast or shake, and when it is too fast, it will greatly exceed the internal setting of the drive. Emergency stop speed (7 degrees / second), will cause pitch system failure.

[0037] For the situation that the feathering speed is too fast or shakes on site, first check the related components and circuits of the pitch control system. If there is no problem, it can be judged that the speed measuring motor is faulty.

[0038] see figure 1 As shown, replacing the tachometer motor in the pitch motor separately includes the following steps:

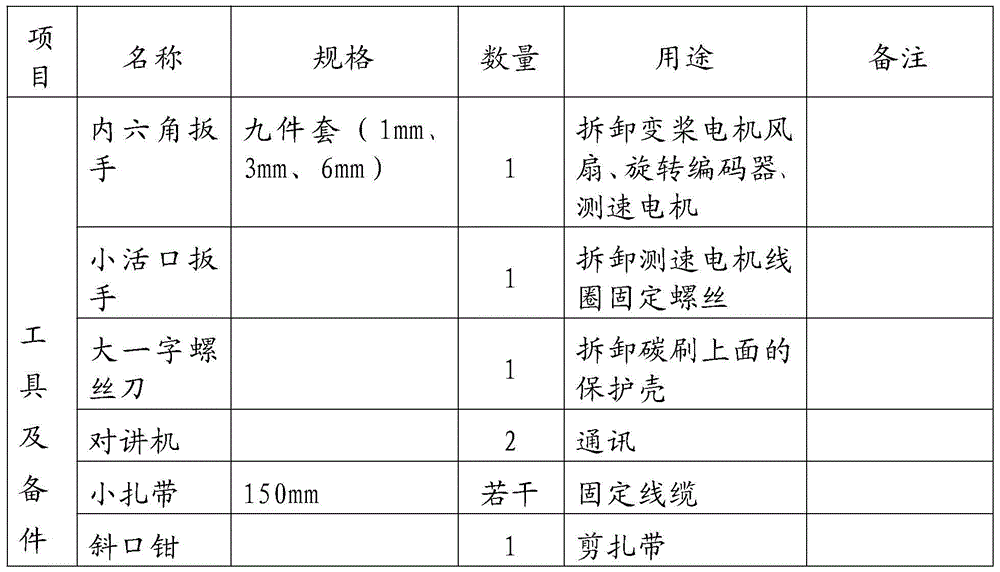

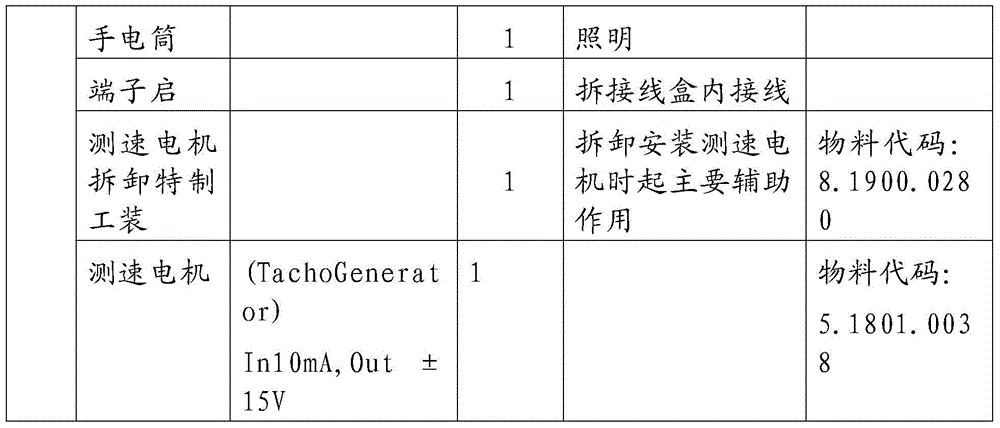

[0039] First of all, for the preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com