Agricultural modern fertilizer blending and irrigation equipment

A fertilizer and agricultural technology, applied in the field of agricultural modern fertilizer blending and irrigation equipment, can solve the problems of uneven distribution of solution concentration, inaccurate proportion of fertilizer blending, and error in the proportion of fertilizer blending, so as to simplify fertilizer blending and fusion operations, and improve equipment. The effect of automation, enhanced efficiency and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

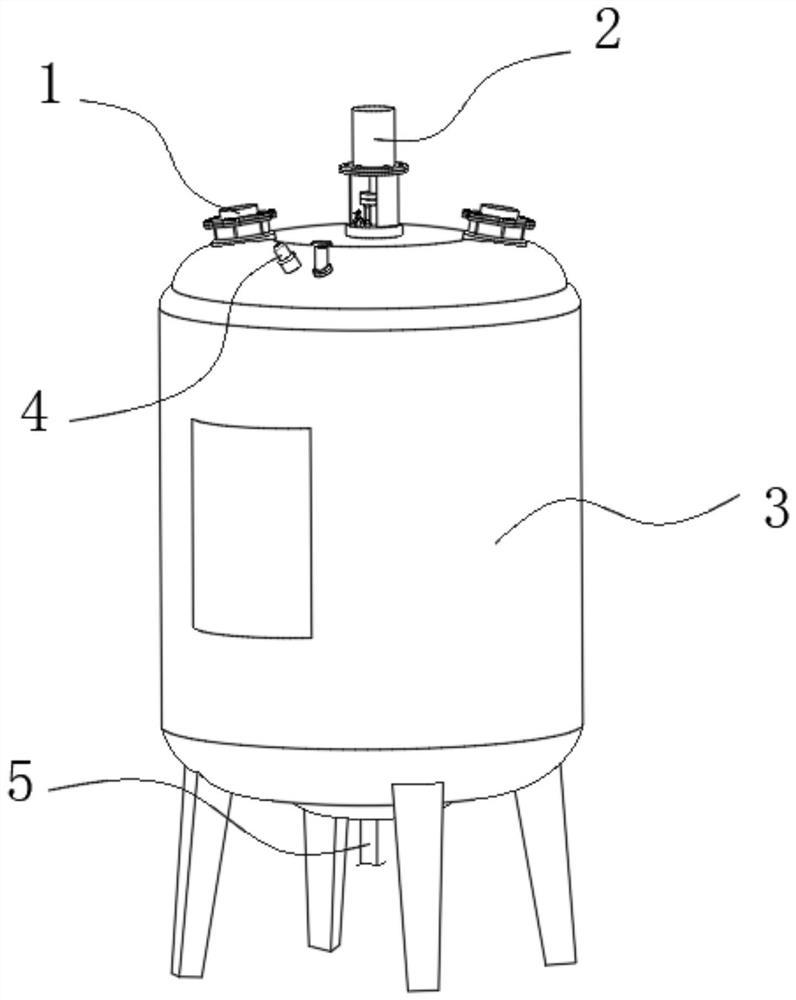

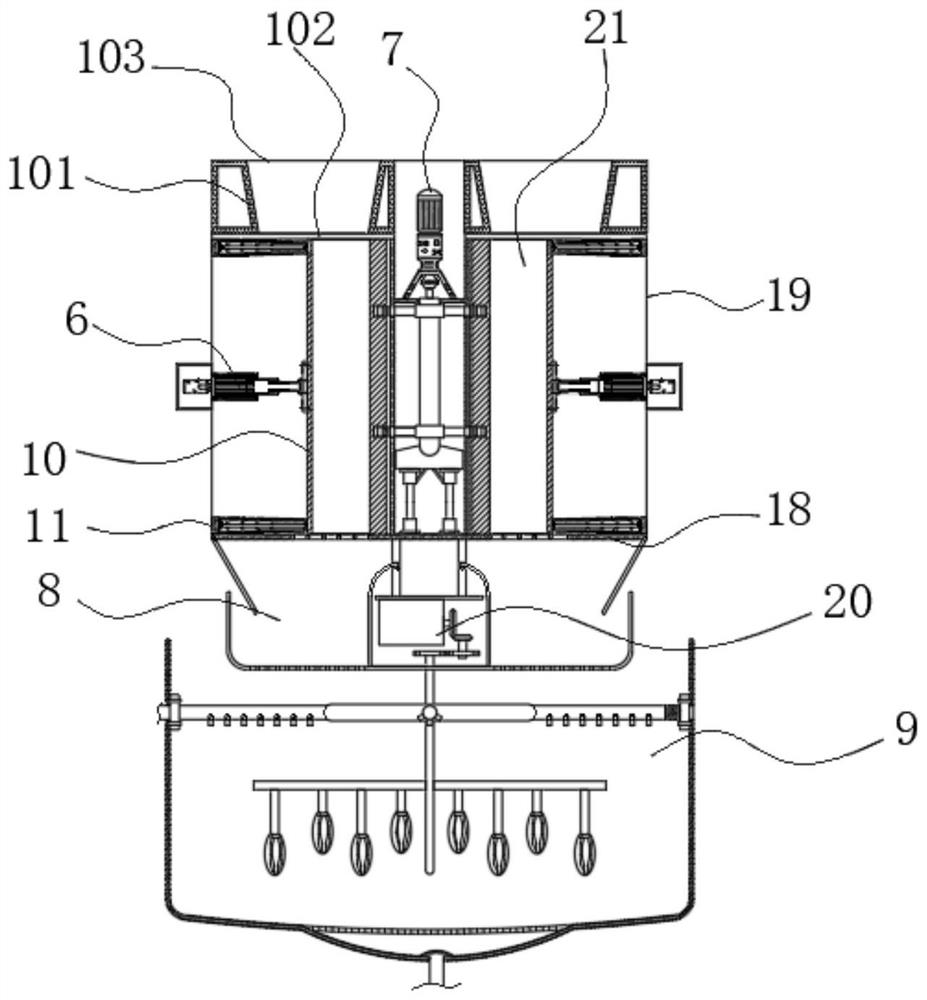

[0030] refer to figure 1 , 2 , 3. The present invention provides a technical solution: a modern agricultural fertilizer deployment and irrigation equipment, which includes a distribution tank 3, a deployment rotating assembly 2, a liquid inlet pipe 4 and a storage device 1, and the shaft center of the distribution tank 3 is provided with The deployment rotating assembly 2, the storage device 1 is connected and fixed above the preparation tank 3, and a plurality of storage devices 1 are arranged in a circular arrangement, the liquid inlet pipe 4 is connected to the upper end flange of the preparation tank 3, and the deployment A drain port 5 is provided at the axis center of the bottom end of the tank 3;

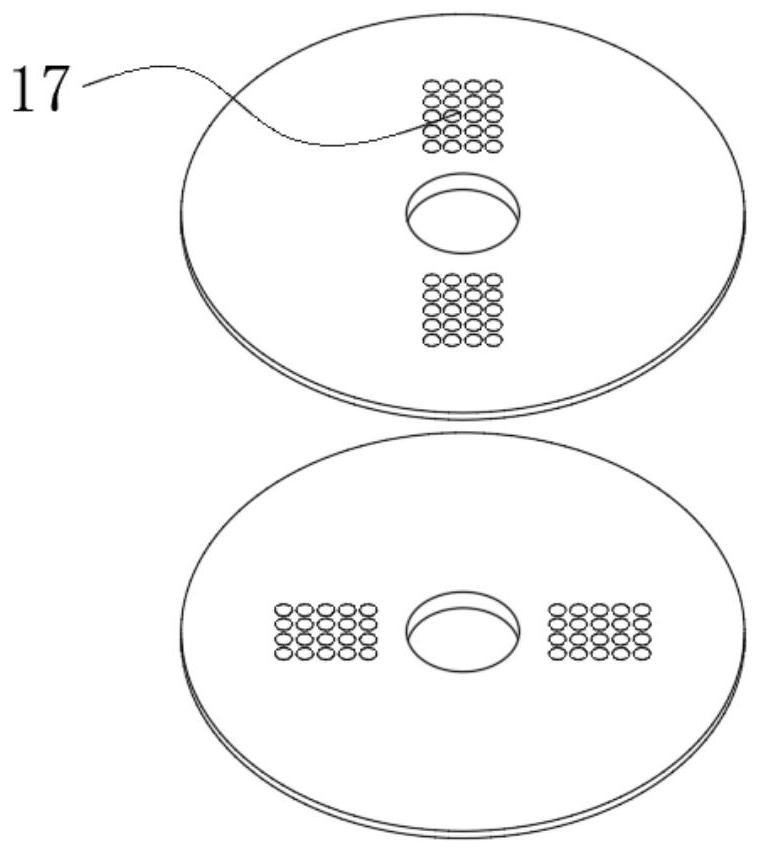

[0031] The fertilizer is stored by the storage device 1 above the deployment tank 3, the volume of a plurality of storage chambers 21 is adjusted by the deployment rotating assembly 2, and the deployment box 19 is rotated by the deployment rotating assembly 2, so that the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com