Potato processing module of automatic food processing device

An automatic processing and potato technology, which is used in food forming, food coating, food processing, etc., can solve problems such as single processing method, serious homogeneity of potato and sweet potato processing, and inability to achieve multi-style processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

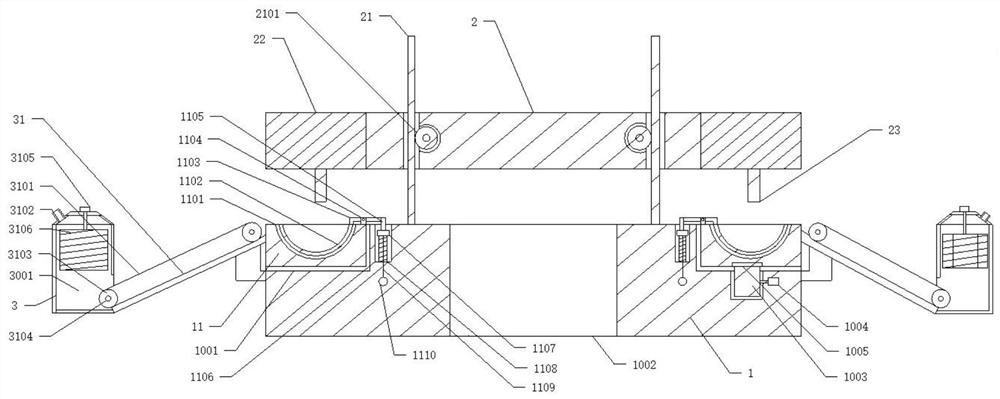

[0043] Such as Figure 1 to Figure 10 As shown, an automatic food processing device includes a potato processing module and a conveying module;

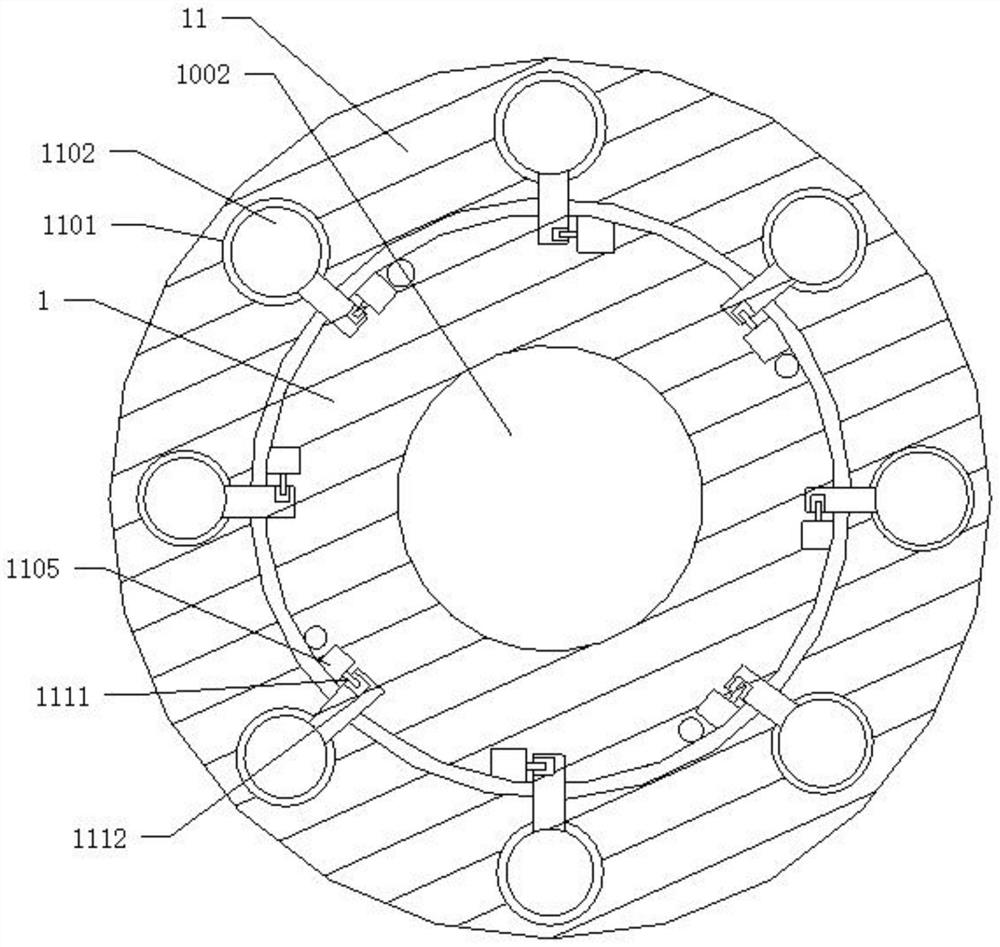

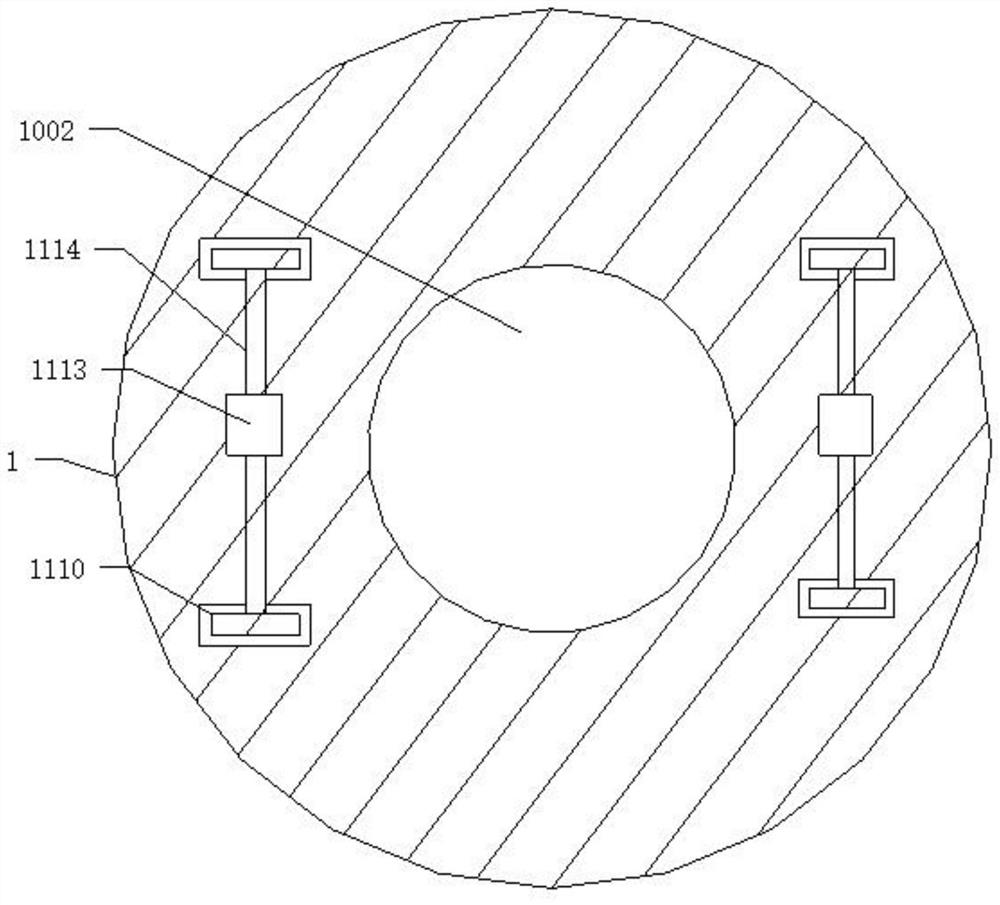

[0044] The potato processing module includes a processing body 1, a processing turntable 11, a pressing turntable 2, a control end 22, and a clamping piece 23. The processing turntable 11 is arranged in an annular shape. Rotate on the body 1, the processing turntable 11 is provided with a plurality of semicircular turntable grooves 1101, the turntable grooves 1101 are respectively provided with a semicircular fixed disk 1102, the processing body 1 is provided with a sliding sliding plate 1107, the sliding plate 1107 drives the fixed plate 1102 to swing synchronously, the processing body 1 is provided with a machine body port 1002, and the fixed plate 1102 swings synchronously with the Corresponding to the body port 1002.

[0045] The processing body 1 is arranged in a circular shape, and the processing turntable 11 is arranged in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com