Fruit juice production filtering device with filter screen convenient to replace

A filter device and filter screen technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of affecting convenience, low processing efficiency, troublesome disassembly of filter devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

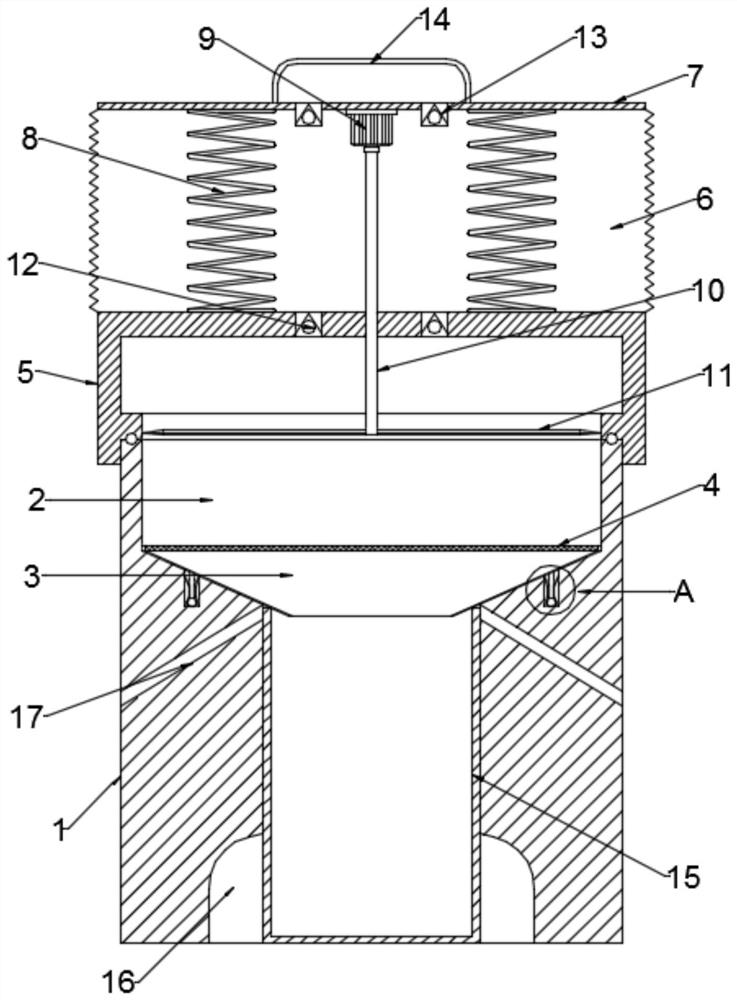

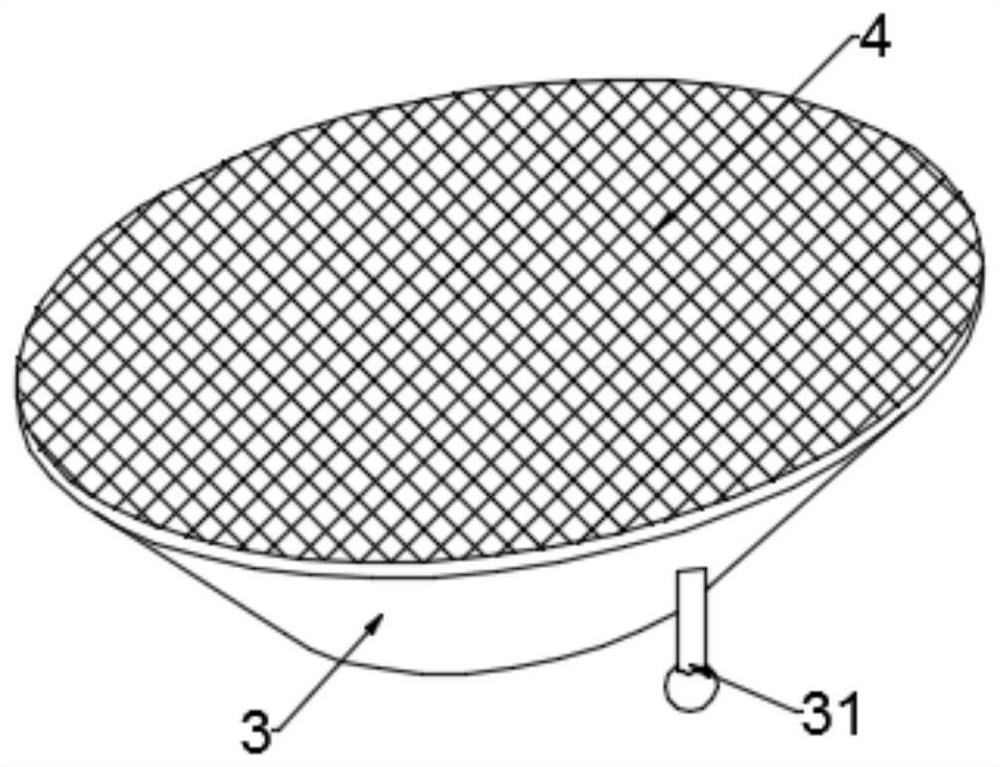

[0023] see figure 1 , in an embodiment of the present invention, a filter device for fruit juice production that is convenient for replacing the filter screen, includes a base 1 and a filter screen 4, the upper end of the base 1 is embedded with a filter cavity 2, and the bottom of the filter cavity 2 is movably assembled and connected A guide ring 3 is provided, the upper end of the guide ring 3 is fixedly connected with a filter screen 4, the upper end of the base 1 is assembled and connected with an upper cover 5, and the upper end of the upper cover 5 is elastically connected with an output end and the The air injection mechanism facing the filter screen 4, the upper cover 5 is slidingly fitted with a crushing mechanism whose output end is opposite to the filter screen 4, and the air injection mechanism and the crushing mechanism are synchronously linked.

[0024] The bottom of the base 1 is slidably embedded with a collection bucket 15, the opening of the collection bucke...

Embodiment 2

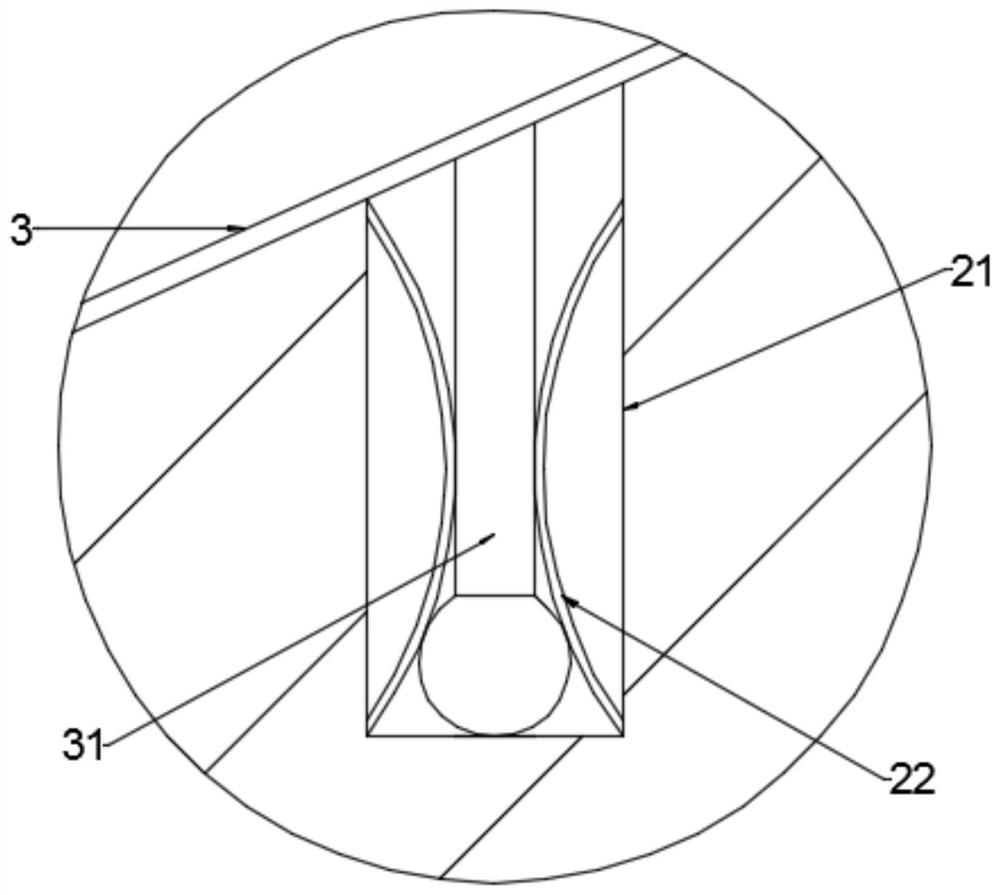

[0031] see Figure 2~3 , in an embodiment of the present invention, a filter device for fruit juice production that is convenient for replacing the filter screen, blind holes 21 are embedded symmetrically on both sides of the bottom of the filter chamber 2, and the symmetrical fixed connections on the two walls of the blind hole 21 are limited. Position piece 22, the two groups of limit pieces 22 are relatively curved arc-shaped spring steel sheets, the lower end of the guide ring 3 and the relative position of the blind hole 21 are fixedly connected with a limit rod 31, and the limit rod 31 31 is composed of a thin rod that slides through the gap between the stoppers 22 and a ball head that is fixedly connected to the end of the thin rod. It is easy to assemble and connect, and is convenient for the replacement of the filter screen 4.

[0032] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com