Step type microfluidic droplet or bubble emulsification module

A micro-droplet, stepped technology, applied in the field of microfluidics, can solve the problems of low channel activation and interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

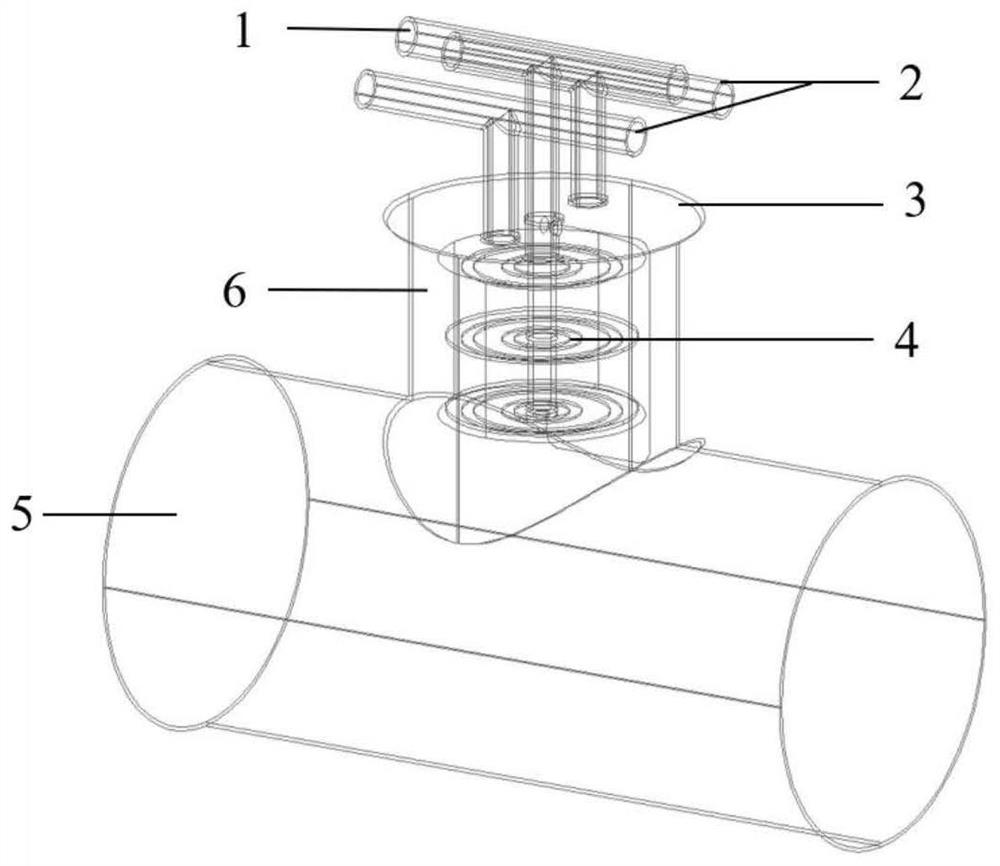

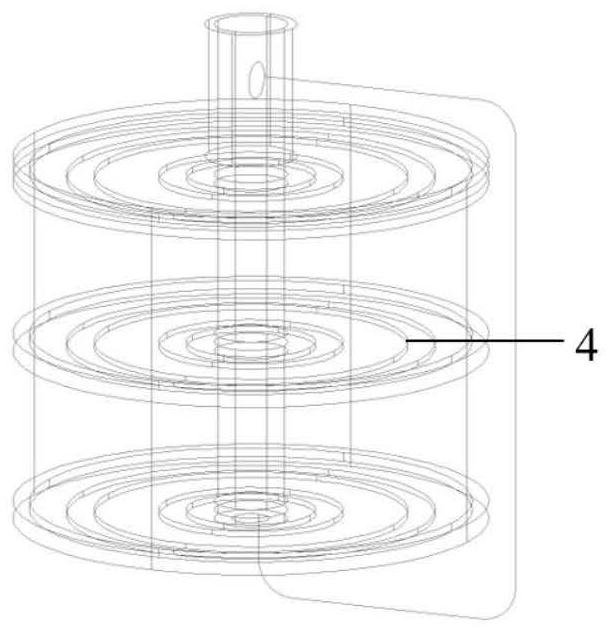

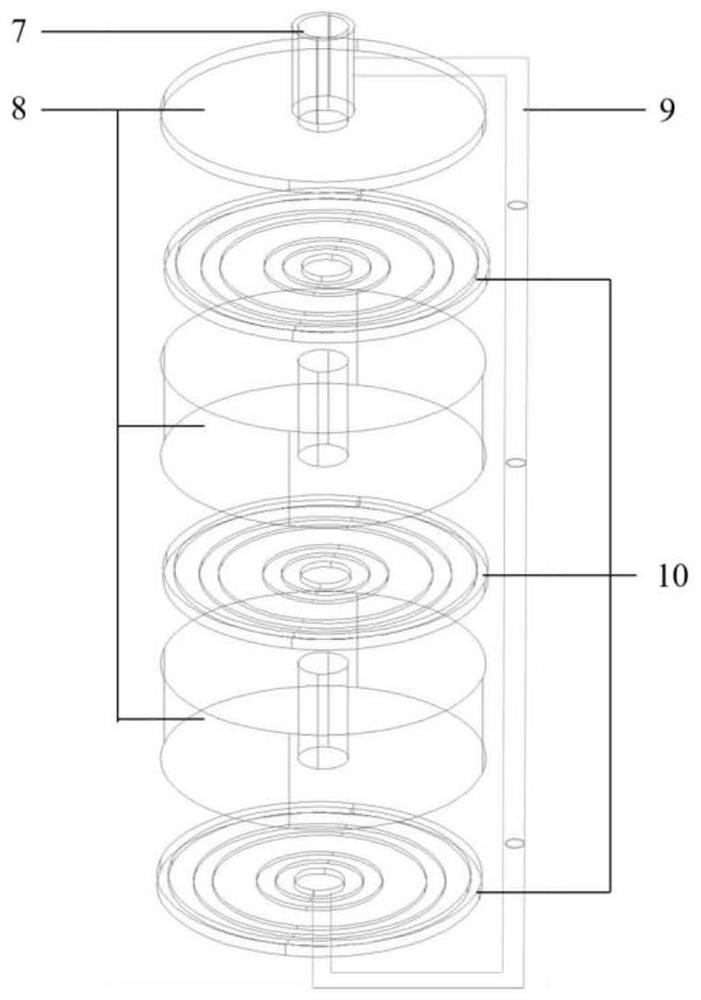

[0031] The structure of the stepped microfluidic droplet / bubble emulsification module of the present invention is as follows: figure 1 As shown, the dispersed phase enters the droplet / bubble emulsifier 4 in the droplet / bubble emulsification chamber 6 through the dispersed phase transportation pipeline 1 in the middle, the continuous phase enters the droplet / bubble emulsification chamber 6 through the continuous phase transportation pipeline 2, and the dispersed phase The droplet / bubble emulsification process is completed in the droplet / bubble emulsifier 4 to generate micro-droplets / bubbles. The droplet / bubble transport channel 5 is in communication with the droplet / bubble emulsification chamber 6, and the micro-droplets generated in the droplet emulsification chamber 6 and the continuous phase in the continuous phase transport pipeline 2 flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com