Thermostatic bath and control method thereof

A constant temperature control and control method technology, which is applied to chemical instruments and methods, laboratory appliances, heating or cooling equipment, etc., can solve the problems of long waiting time, high energy consumption, frequent heating and cooling, etc., and achieve short waiting time and low energy consumption. The effect of low energy consumption and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

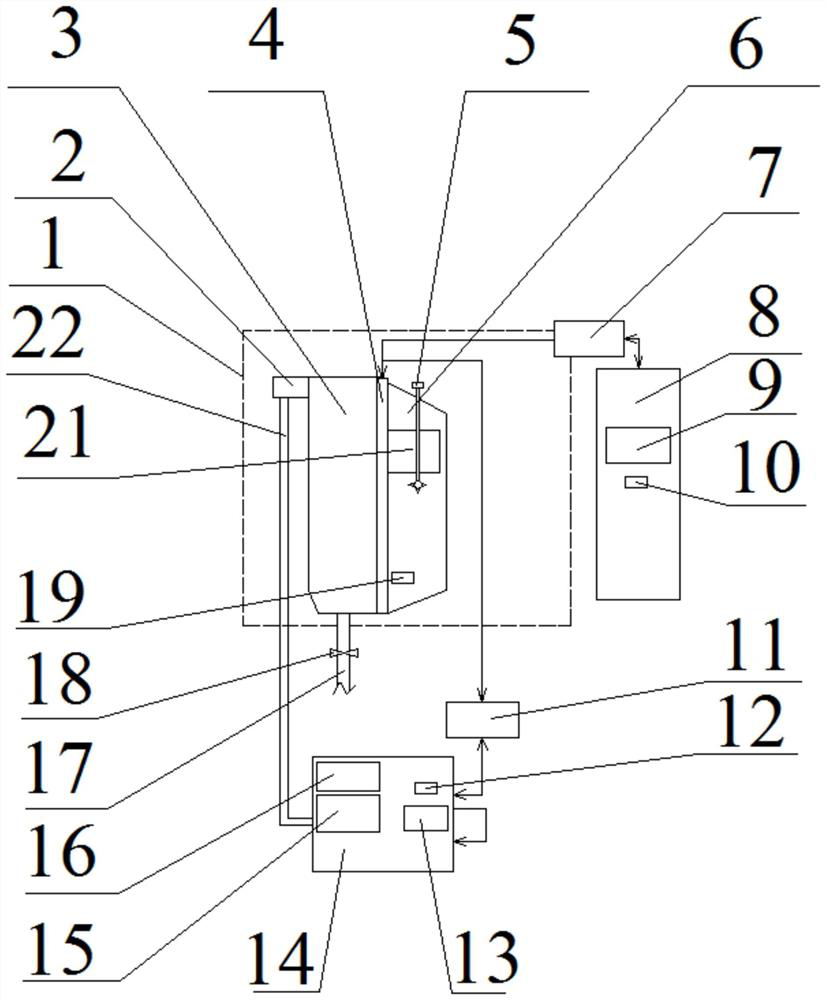

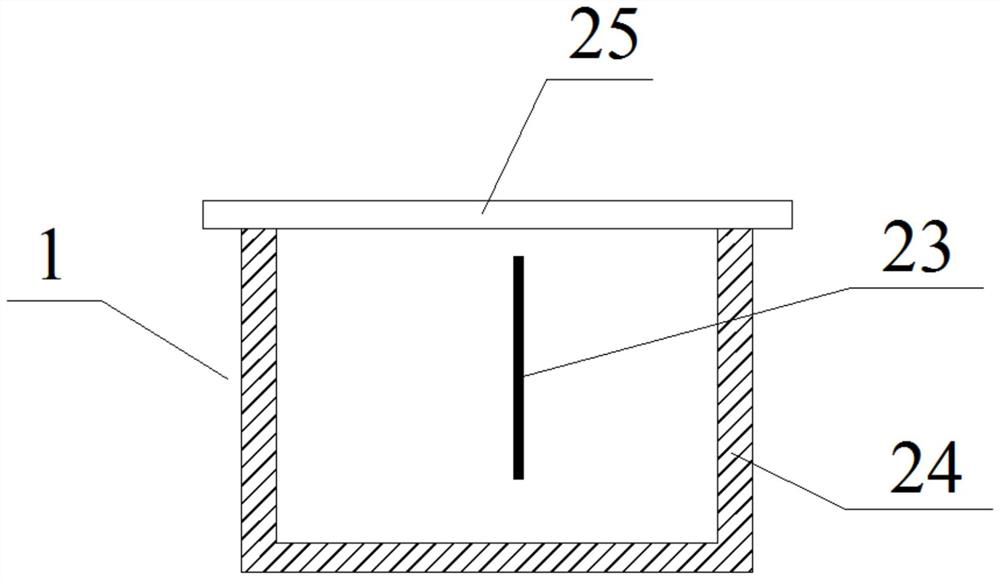

[0041] Such as figure 1 , a constant temperature tank, including a constant temperature tank body 1, and also includes a heating chamber 8 and a cooling chamber 14 communicated with the constant temperature tank body 1, and the heating chamber 8 passes through the second bidirectional pump 7 or at least two unidirectional pumps The combination introduces or exports the circulating high-temperature working medium into the constant temperature tank 1, and the refrigeration chamber 14 introduces or exports the circulating low temperature working medium into the constant temperature tank 1 through the first two-way pump 11 or a combination of at least two unidirectional pumps. working medium.

[0042] Working process: when switching between high and low temperature, turn on the second two-way pump 7 to transport the high-temperature working medium in the working chamber 3 to the heating chamber 8, then turn off the second two-way pump 7, turn on the first two-way pump 11, and turn...

Embodiment 2

[0045] Such as figure 1 , On the basis of Embodiment 1, a third heater 9 and a third temperature control sensor 10 are arranged in the heating chamber 8 . It plays the role of pre-heating and pre-controlling the high-temperature working medium in the heating chamber 8.

Embodiment 3

[0047] Such as figure 1 , On the basis of Embodiment 1, a second heater 16 , a refrigeration evaporator 15 and a second temperature control sensor 12 are arranged in the refrigeration chamber 14 . The second heater 16 is used for heating the low-temperature working medium, the refrigeration evaporator 15 is used for cooling the low-temperature working medium, and the second temperature control sensor 12 is mainly used for testing the heating and cooling speed and the temperature of the low-temperature working medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com