A process for extracting and separating micropowder from iron and steel smelting converter steel slag

A converter steel slag and iron and steel smelting technology, which is applied in the field of iron and steel smelting, can solve problems such as waste, metal iron powder mixed into water, and large water consumption, and achieve the effect of simple structure, avoiding waste, and saving expenditure and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

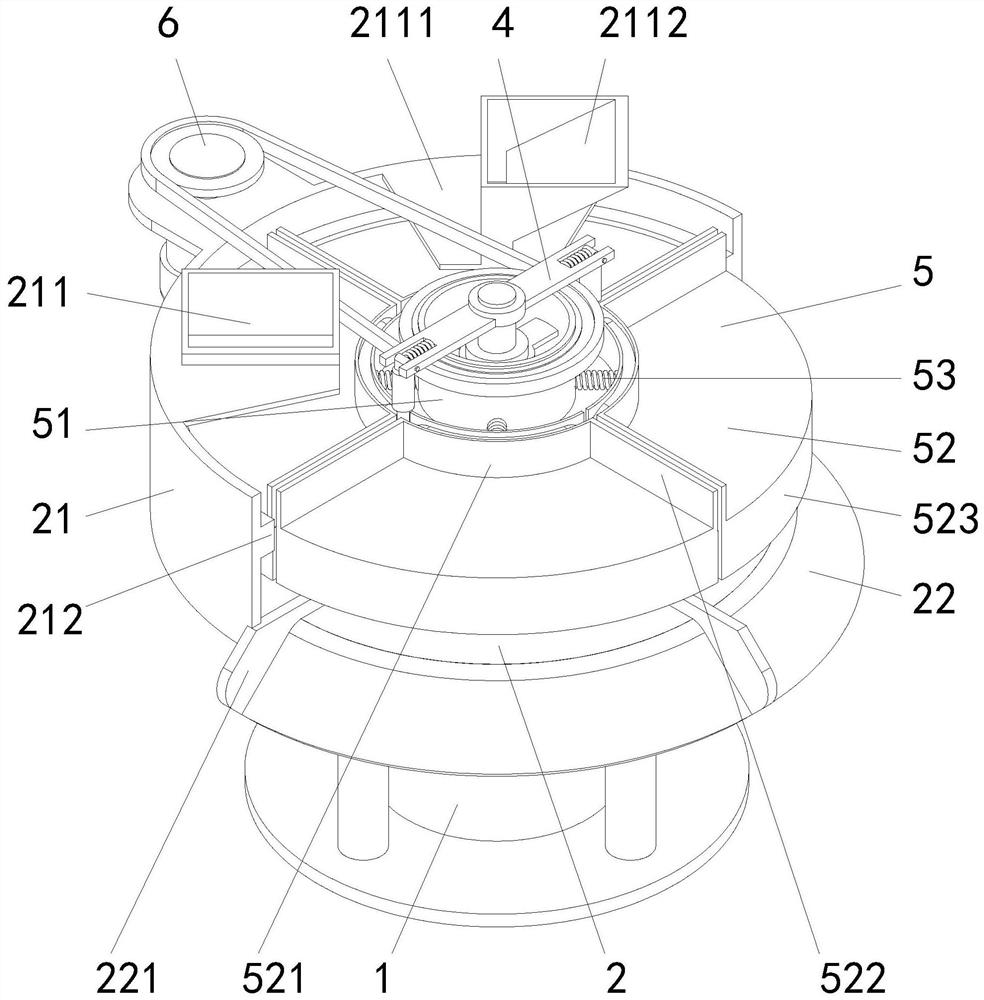

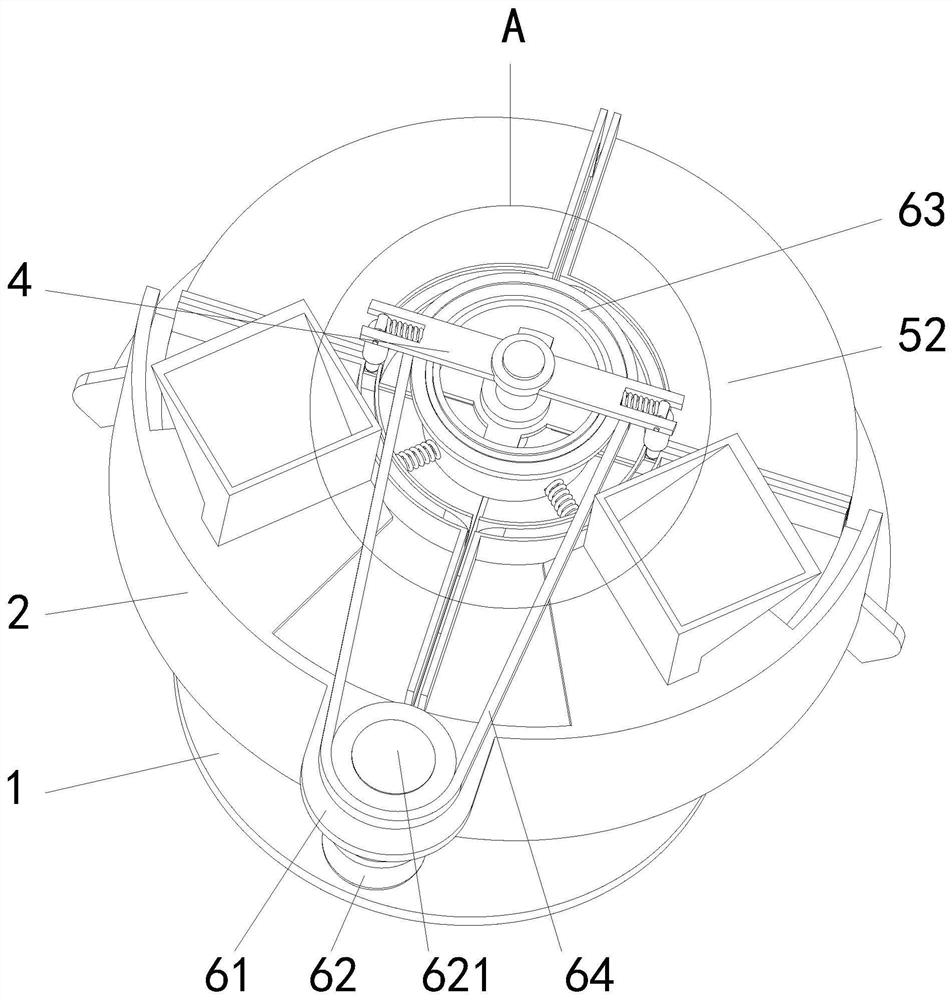

[0038] The following is a comparison with the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention will be further elaborated, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept of the present invention, technical solutions, and contribute to its implementation, but not as a limitation of the present invention.

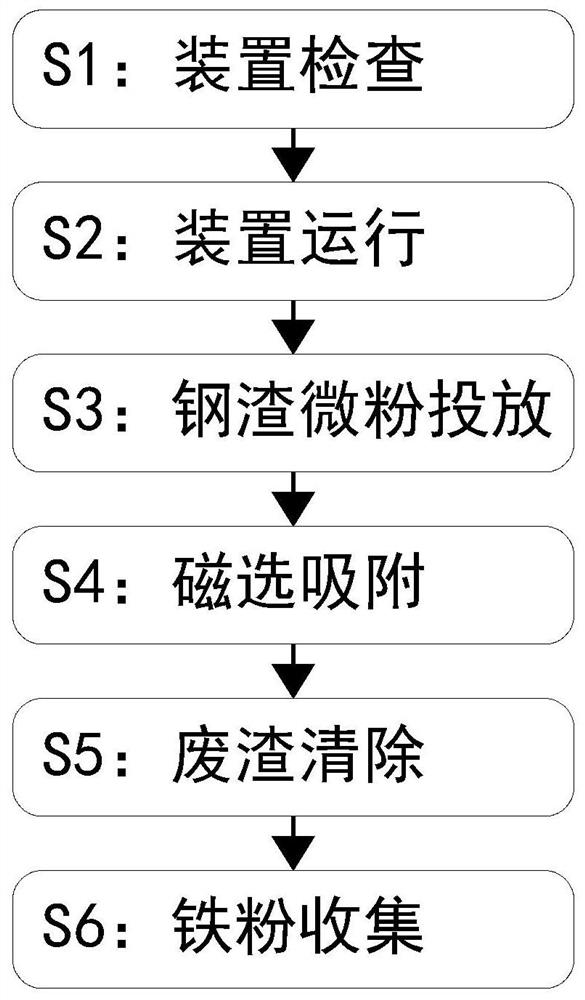

[0039] See Appendix Figure 1-8 As shown, a steel smelting converter steel slag treatment micronized powder extraction and separation process, the separation process specifically includes the following steps:

[0040] S1, device inspection: a kind of steel smelting converter steel slag treatment micro powder extraction and separation device is inspected to ensure that it can operate normally in the process of steel slag treatment of steel slag extraction and separation;

[0041] S2, the operation of the device: start a steel smelting conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com