An accessory painting equipment for rattan chair frame

A painting equipment and skeleton technology, which is applied in painting booths, spraying devices, liquid spraying devices, etc., can solve problems such as troublesome painting operations, and achieve the effects of convenient operation, long-lasting use, and uniform spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

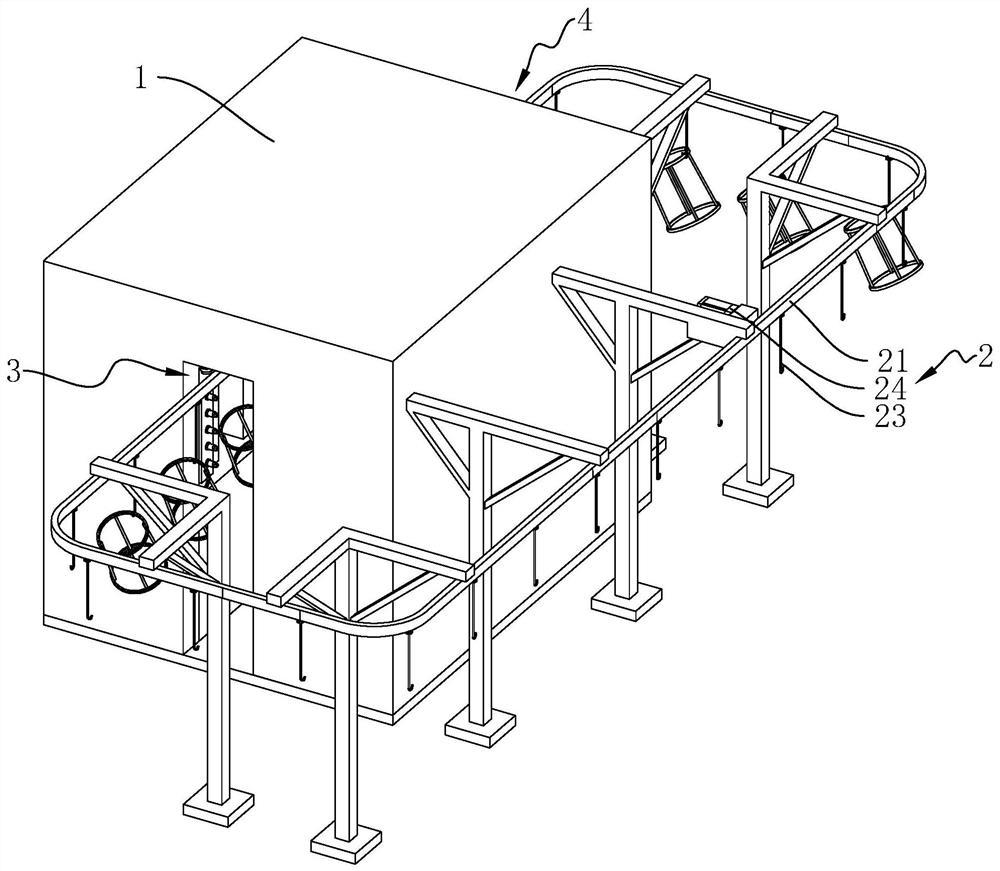

[0047] An accessory painting equipment for rattan chair skeleton, such as figure 1 As shown, it includes a painting room 1 and a suspension conveyor 2, and the suspension conveyor 2 is erected on the ground.

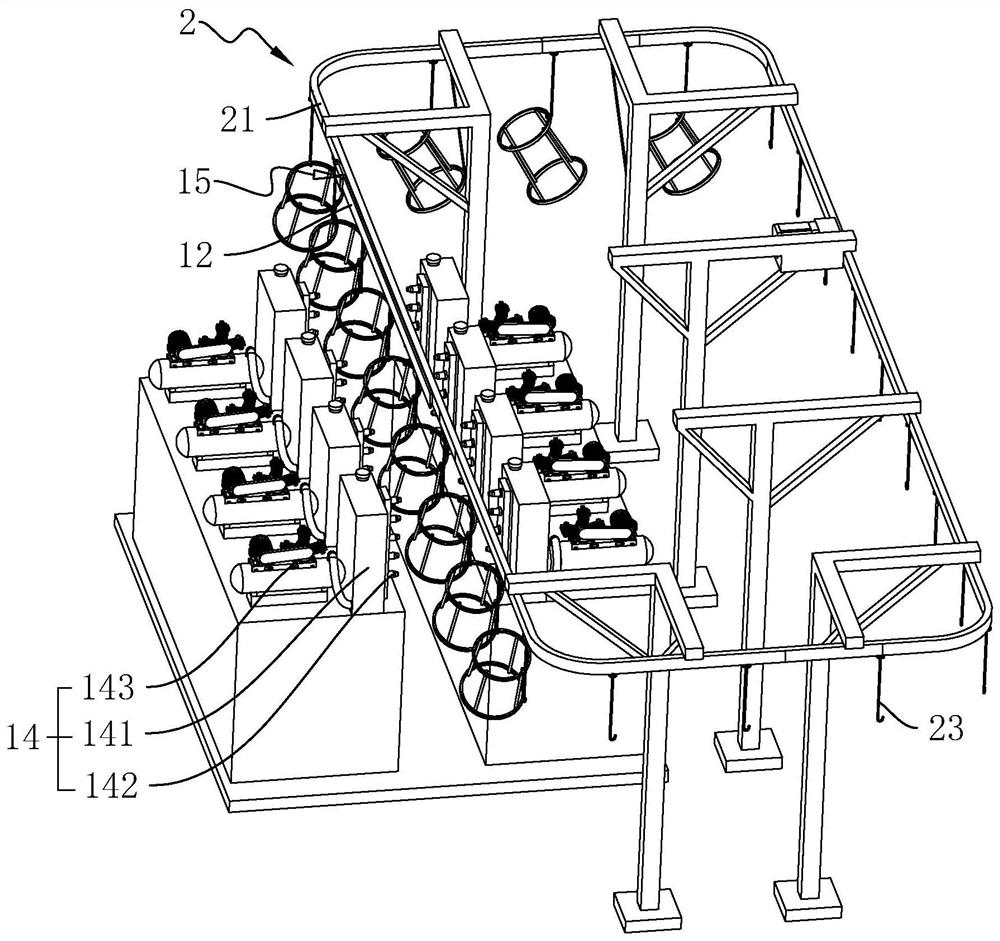

[0048] Such as figure 2 , image 3As shown, the suspension conveyor 2 includes a carriage track 21, a traction chain 22 arranged in the carriage orbit 21, a hanger 23 arranged on the traction chain 22 and a driving device 24 arranged on the carriage rail 21, and the driving device 24 is generally a motor, and the driving device 24 is fixed on the carriage track 21, and the driving device 24 is mainly used to drive the traction chain 22 to run. The carriage rail 21 is provided in a ring shape, and the carriage rail 21 is arranged through the painting booth 1 , so that the suspension conveyor 2 is annular and passes through the painting booth 1 . An inlet 3 and an outlet 4 are respectively provided on the spray booth 1 where the carriage rail 21 passes through. The lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com