Perforating device and perforating method of wind power blade

A technology for drilling devices and wind turbine blades, which is applied in the direction of drilling templates for workpieces, etc., can solve the problems of difficult dimensions, failure to meet the size requirements of drawings, and inability to ensure consistency, etc., to achieve the effect of reducing size errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

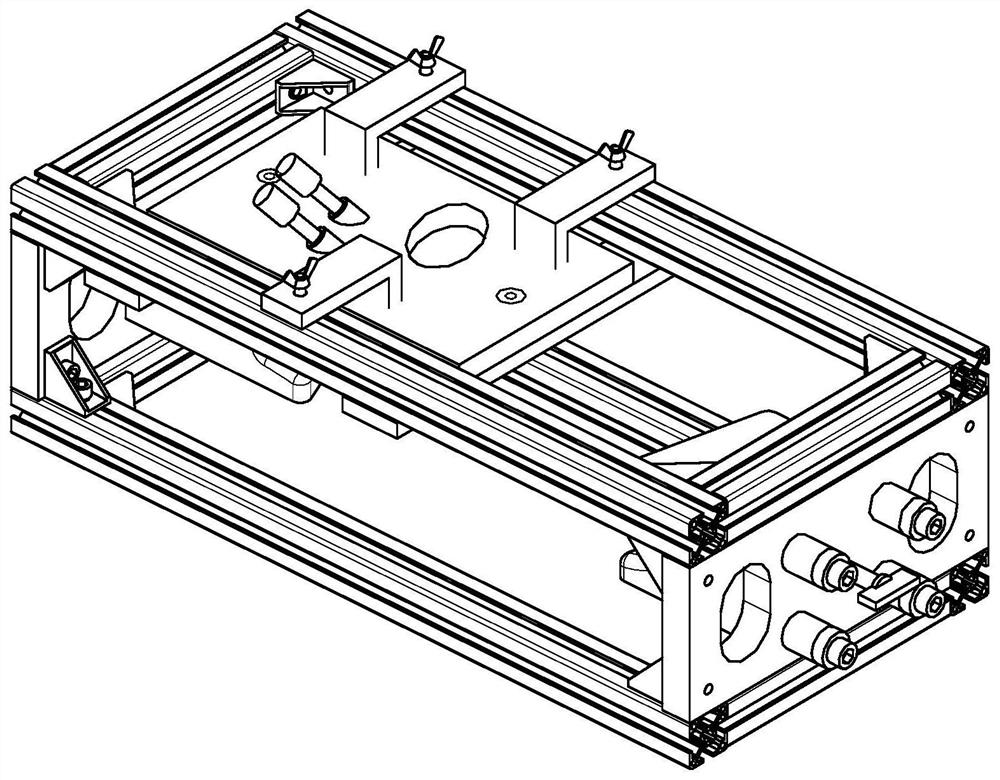

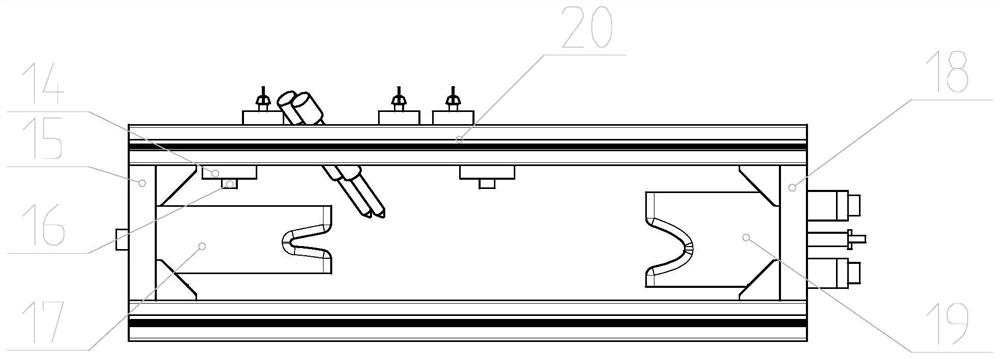

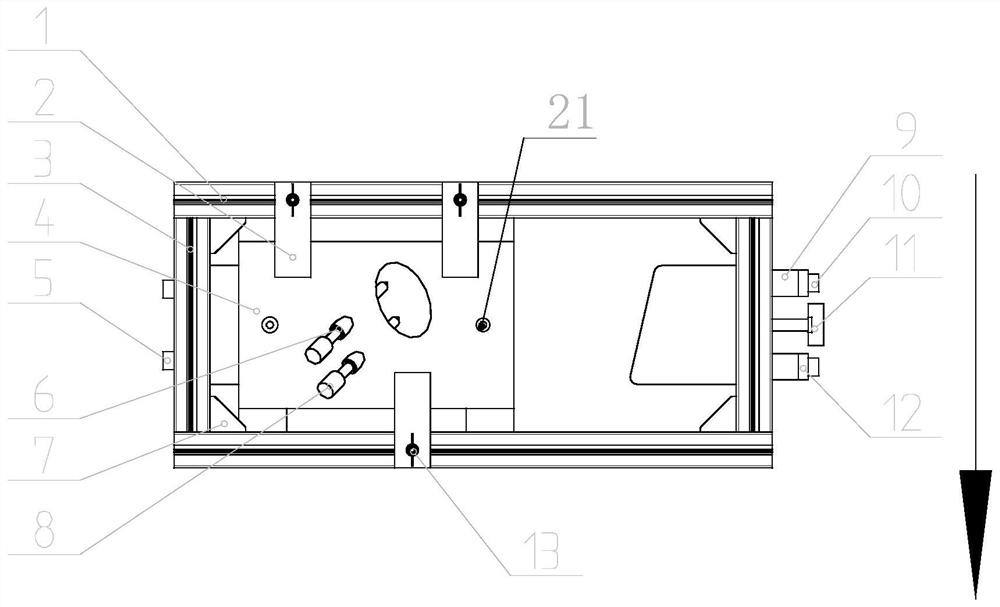

[0029] As shown in the figure, the beam 1 and the longitudinal beam 3 of the present invention form the upper frame and the lower frame of the device, the upper and lower frames are supported and connected by the first side plate 15 and the second side plate 18, and each connection point is reinforced by a corner piece 7 connection, the upper end and the middle part of the lower end of the crossbeam 1 are respectively provided with tracks for the sliding of the second wing bolt 13 and the locking bolt 16, the first side plate 15 is connected to the fixed limit plate 17 by the first bolt 5, and the second side plate 18 is connected with the accompanying limit block 19 through the unloading bolt 10, and the rectangular spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com