Welding forming correction treatment process for chemical tank manufacturing

A technology of welding forming and processing technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing, etc., can solve the problems of high labor intensity, large safety hazards, complex correction procedures, etc., and achieve the goal of improving efficiency and quality, and improving quality and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

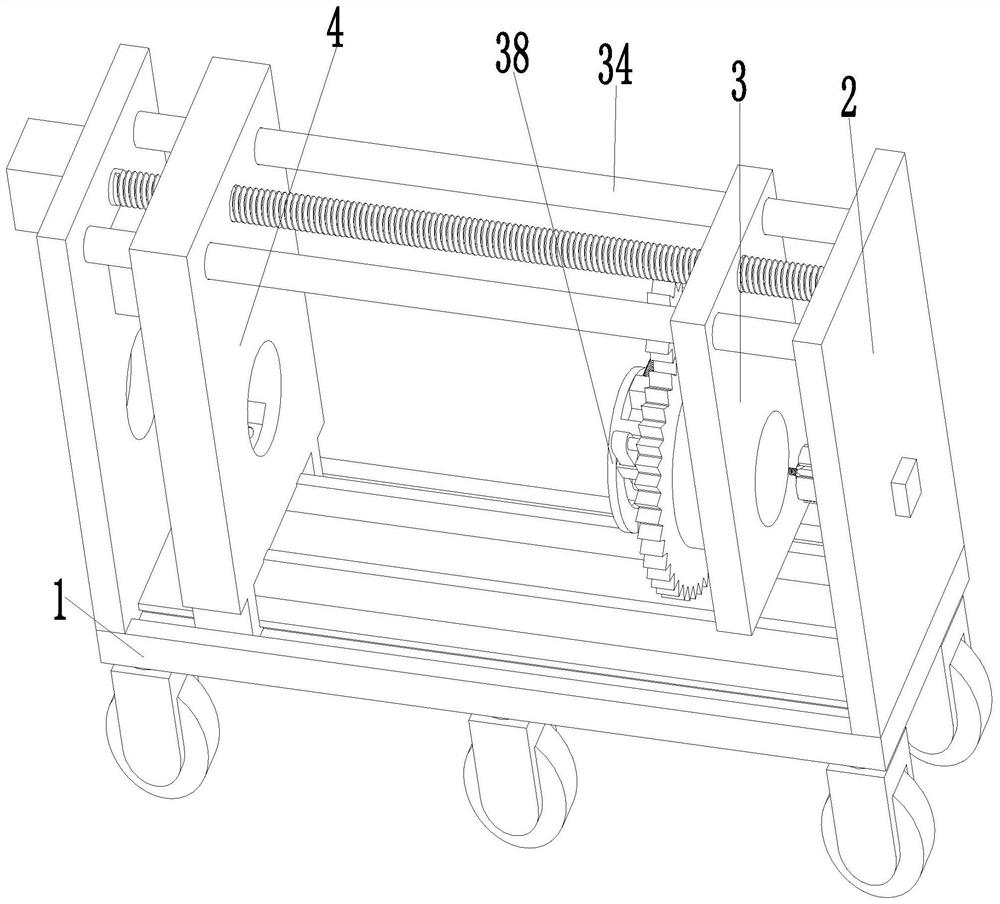

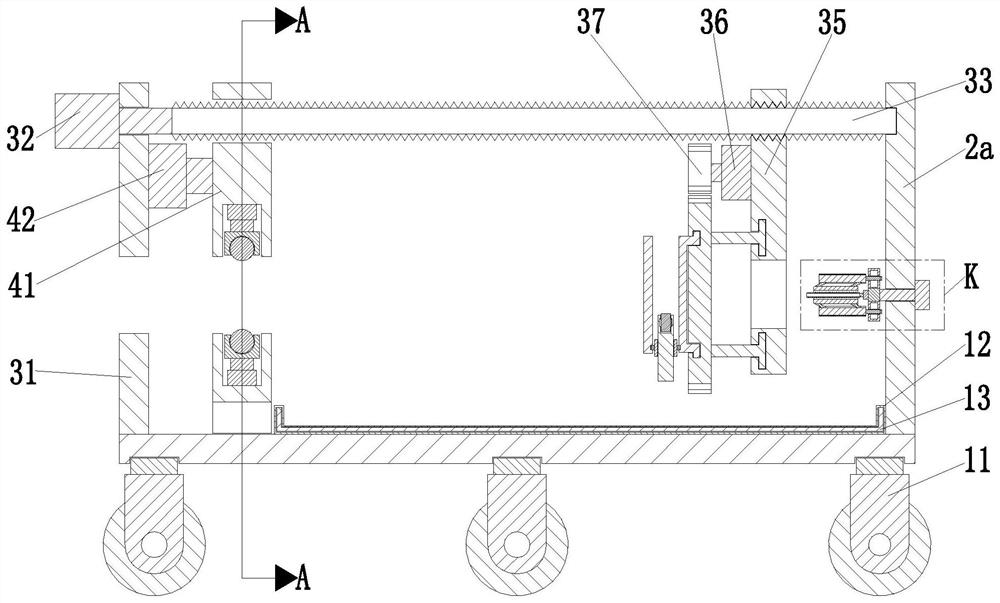

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

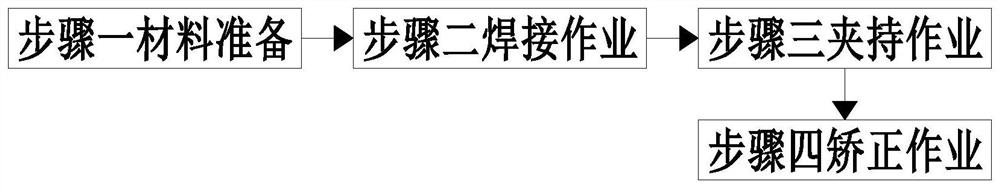

[0033] like Figure 1 to Figure 7 As shown, a chemical tank manufacturing welding forming correction treatment process mainly includes the following steps:

[0034] Step 1, material preparation, prepare the raw materials required for the manufacture of chemical tanks, and obtain the raw materials for the tanks;

[0035] Step 2, welding operation, performing welding operation on the raw material of the tank body obtained in step 1 to obtain a welded and formed tank body;

[0036] Step 3, clamping operation, performing clamping and positioning operations on the welded and formed tank body through the clamping device 2 and the abutting device 4, to obtain a clamped and positioned tank body;

[0037] Step 4, rectification operation, correcting and cle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap