A split mold

A split type, mold technology, applied in the direction of molds, mold auxiliary parts, manufacturing tools, etc., can solve the problems of ceramic defects, gypsum entering the gap, etc., and achieve the effect of improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

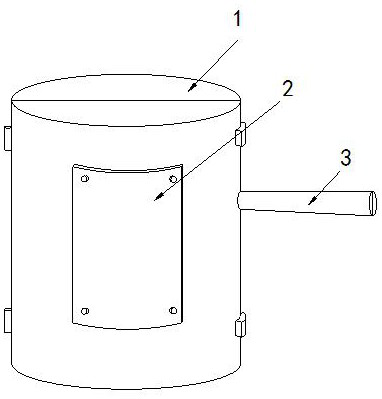

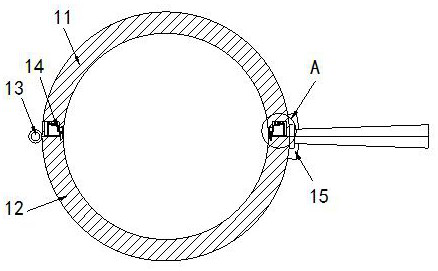

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

[0027] Its structure includes a main body 1, a model plate 2, and a handle 3. The side end of the main body 1 is provided with a model plate 2, and the handle 3 is installed in the middle of the side end of the main body 1. The main body 1 includes an upper module 11, a lower module 12, rotating shaft 13, rolling device 14, closing switch 15, the other side of described upper module 11 is provided with lower module 12, and described rotating shaft 13 connects upper module 11 and lower module 12, and described rolling device 14 It is arranged in the upper module 11 and movably cooperates with the lower module 12 .

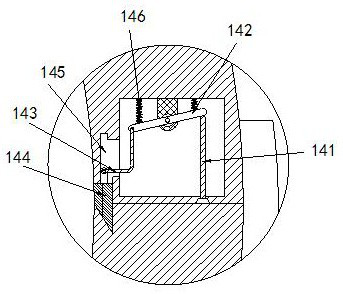

[0028] The flattening device 14 includes a push rod 141, a balance bar 142, a push rod 143, a smoothing block 144, a slide groove 145, and a first spring 146. Movably fit, the balance bar 142 is engaged on the top of the rolling device 14, the...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The smoothing block 144 includes a rolling groove b1, a roller b2, a movable rod b3, an elastic piece b4, and a smoothing body b5. The rolling groove b1 is arranged at the side end of the smoothing block 144. , and installed in the rolling groove b1, the movable rod b3 is provided with two, and installed crosswise in the roller b2, the elastic sheet b4 connects the two movable rods b3, and the smoothing body b5 is embedded in At the end of the movable rod b3, the included angle between the smoothing blocks 144 is 120 degrees, which is beneficial to smoothing the protruding gypsum.

[0034] The smoothing body b5 includes a fixed block b51, a mud collecting groove b52, a groove b53, and a plastering block b54. There are two fixed blocks b51, which are located at the bottom of the smoothing body b5 and move with the movable rod b3 Cooperate, the said...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com