Anti-rotation device and anti-rotation method for cylinder barrel of pushing oil cylinder of extruder

A technology for pushing oil cylinders and extrusion machines, which is applied in the field of aluminum profile extrusion machines. It can solve the problems of anti-rotation of the cylinder barrel of the pushing oil cylinder, affecting production stability, and defects on the aluminum alloy surface, so as to avoid defects, improve production quality, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

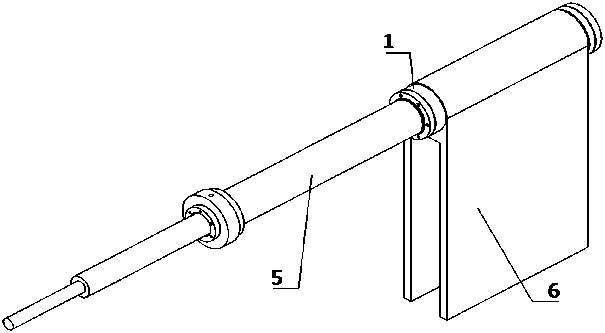

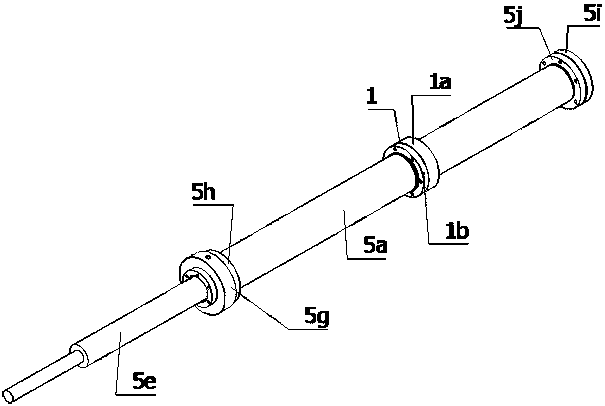

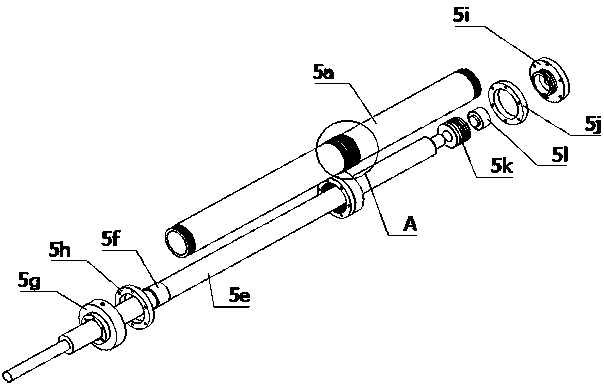

[0044] refer to Figure 1 to Figure 4The illustrated anti-rotation device for pushing the cylinder barrel of an extrusion machine includes a mounting seat 6, a pushing cylinder assembly 5 and a locking mechanism 1, and the pushing cylinder assembly 5 is installed on the mounting seat 6 for locking the pushing cylinder assembly 5. The locking mechanism 1 tightly fixed on the mounting base 6 is fixedly installed on the mounting base 6, and the push cylinder assembly 5 includes a cylinder barrel 5a, a piston rod 5e, an inner copper sleeve 5f, a front end cover 5g, a front flange 5h, and a rear end cover 5i , the rear flange 5j, the piston 5k and the rear end cover 5i, one end of the cylinder 5a passes through the mounting seat 6, and the cylinder 5a is detachably connected with the locking mechanism 1, and the two ends of the cylinder 5a are provided with external threads, The rear flange 5j is engaged on the external thread of one end of the cylinder 5a, and the rear flange 5j i...

no. 2 approach

[0049] refer to Figure 5 In the illustrated anti-rotation device for pushing the oil cylinder of the extruder, the parts that are the same as or corresponding to those in the first embodiment use the same reference numerals as those in the first embodiment, and the reference numerals of the locking mechanism and the cylinder correspond to those of the first embodiment. Adjustment, for example, in the first embodiment, the reference number of the locking mechanism is 1, in the second embodiment, the reference number of the locking mechanism is 2, and the cylinder is similar. For the sake of brevity, only the differences between the second embodiment and the first embodiment will be described below, and repeated descriptions will be omitted. The locking mechanism 2 is a clasp 2a, and the clasp 2a is sleeved on the outer edge of the cylinder 5b, and several clamping strips 5b1 are fixedly arranged on the outer edge of the cylinder 5b, and several clamping strips 5b1 are arranged...

no. 3 approach

[0051] refer to Figure 6 and Figure 7 In the illustrated anti-rotation device for pushing the oil cylinder of the extruder, the parts that are the same as or corresponding to those in the first embodiment use the same reference numerals as those in the first embodiment, and the reference numerals of the locking mechanism and the cylinder correspond to those of the first embodiment. Adjustment, for example, in the first embodiment, the reference number of the locking mechanism is 1, in the third embodiment, the reference number of the locking mechanism is 3, and the cylinder is similar. For the sake of brevity, only the differences between the third embodiment and the first embodiment will be described below, and repeated descriptions will be omitted. The locking mechanism 3 includes a fixed ring 3a and two fastening screws 3b. The fixed ring 3a is sleeved on the outer edge of the cylinder 5c, and the fixed ring 3a is fixedly connected with the mounting base 6 by screws. On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com