Welding agent storing and heating equipment

A technology for heating equipment and flux, applied in welding equipment, metal processing equipment, auxiliary devices, etc., can solve problems such as poor protection effect, and achieve the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below through specific examples.

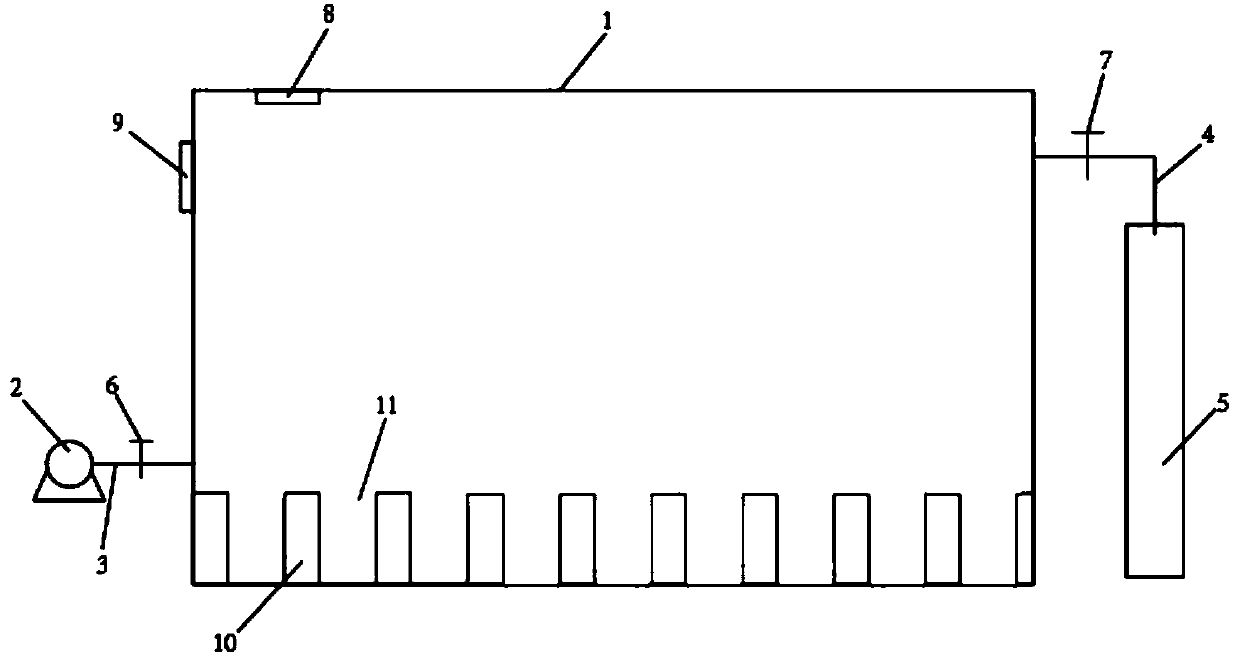

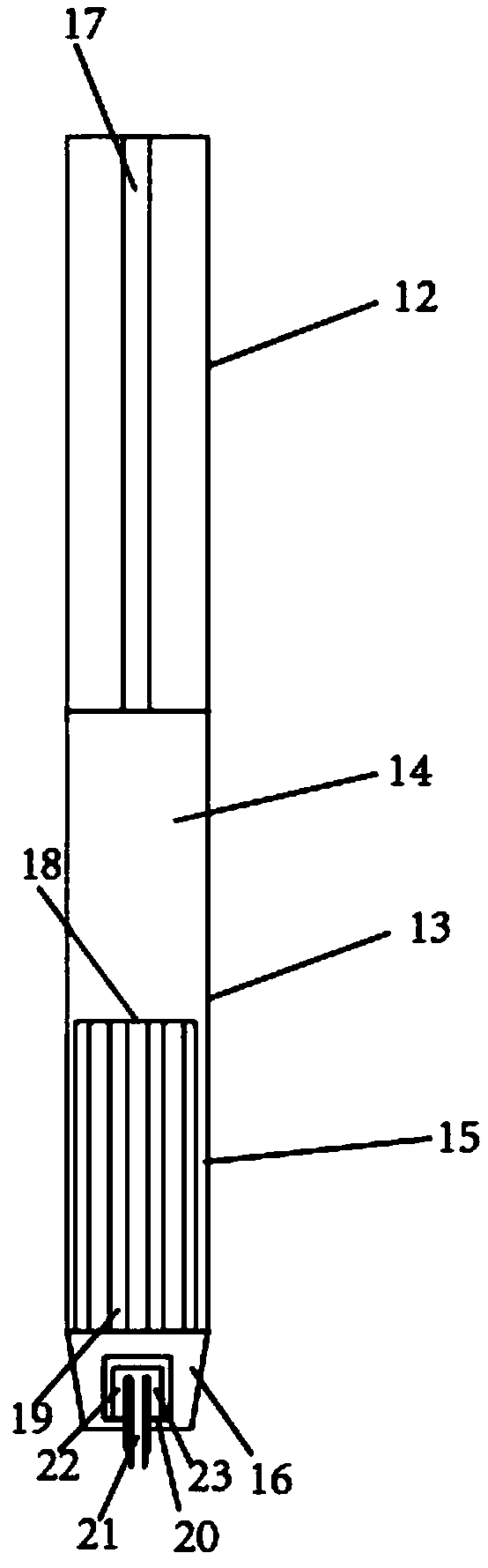

[0015] like figure 1 and figure 2 As shown, among them, 1 is the storage bin, 2 is the exhaust pump, 3 is the exhaust pipe, 4 is the intake pipe, 5 is the protective gas storage tank, 6 is the exhaust valve, 7 is the intake valve, and 8 is the pressure detector , 9 is a pressure controller, 10 is a placement frame, 11 is a placement hole, 12 is a hand-held part, 13 is a high temperature resistant container, 14 is a flux chamber, 15 is a melting chamber, 16 is a lead-out device, 17 is a lead hole, 18 19 is a guide hole, 20 is a flux controller, 21 is a longitudinal outlet pipe, 22 is an L-shaped outlet left pipe, and 23 is an L-shaped outlet right pipe.

[0016] Flux storage and heating equipment, including storage bins, storage devices, exhaust pumps, exhaust pipes, intake pipes, pressure detectors and protective gas storage tanks. The storage devices are pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com